Best Devices for Hydraulic Oil Reservoir Tank Level Monitoring

Level Measurement in the Hydraulic Oil Reservoir Tank: Precision That Powers Performance

In industrial systems reliant on hydraulic power, accurate level measurement in the hydraulic oil reservoir tank is not just important, it is absolutely critical. Hydraulic oil circulates throughout the system, and over time, gradual losses occur from leak points and lubrication paths. Without proper detection and timely refilling, these losses can result in pump cavitation, reduced system efficiency, and ultimately damage to key equipment components, leading to costly downtime.

Hydraulic oil reservoirs are typically designed with a measuring range of up to 2 meters and operate in environments ranging from 0 to +50°C under atmospheric pressure. However, the composition of hydraulic oil can change over time due to aging, contamination, or thermal variations. These changes can affect the oil’s properties and dielectric constant, making it even more important to have accurate and reliable level detection in place to ensure the system operates optimally.

Application in Hydraulic Oil Reservoir Tanks

Hydraulic systems face a variety of environmental and operational challenges. These include:

- Oil composition variations: Aging or contamination can alter the oil’s dielectric constant, making it harder to measure levels accurately.

- Low-pressure and low-temperature environments: Hydraulic systems often operate in a wide range of conditions, from high pressures to low temperatures.

- Space constraints: Hydraulic oil tanks are often installed in tight spaces, requiring compact measurement solutions.

- Non-contact or minimally intrusive measurement technologies: In many applications, non-contact measurement technologies are preferred to avoid fouling, wear, or contamination.

Jiwei offers advanced solutions tailored to meet the specific requirements of hydraulic oil applications, ensuring accuracy, reliability, and minimal maintenance.

Jiwei’s Recommended Level Measurement Devices for Hydraulic Oil Reservoir Tanks

Rada-31 Radar Level Meter

The Rada-31 radar level meter is a highly reliable non-contact solution, utilizing 80GHz FMCW technology to deliver accurate measurements even in challenging conditions. With the ability to detect low-dielectric liquids like hydraulic oil, it performs exceptionally well in environments where oil composition varies, and external factors such as foam, vapor, or surface agitation could otherwise interfere with measurements.

Key Benefits:

- Non-contact measurement: Prevents issues like fouling and wear, reducing the need for maintenance.

- Effective in varying oil compositions: The radar technology is not affected by changes in oil properties, ensuring accuracy despite contamination or aging oil.

- Remote setup: Configure and monitor the device using the 计为智控 Bluetooth mini-program, making it ideal for remote and hard-to-reach locations.

- Wide operating range: -40 to +200°C, which is suitable for most hydraulic oil environments.

- Compact design: Perfect for tight spaces in hydraulic systems, enabling installation in confined areas.

- Explosion-proof version: Available for use in hazardous environments, ensuring safety in critical applications.

The Rada-31 radar level meter offers reliable, maintenance-free performance for continuous level monitoring in hydraulic oil reservoir tanks, making it an ideal choice for industrial applications.

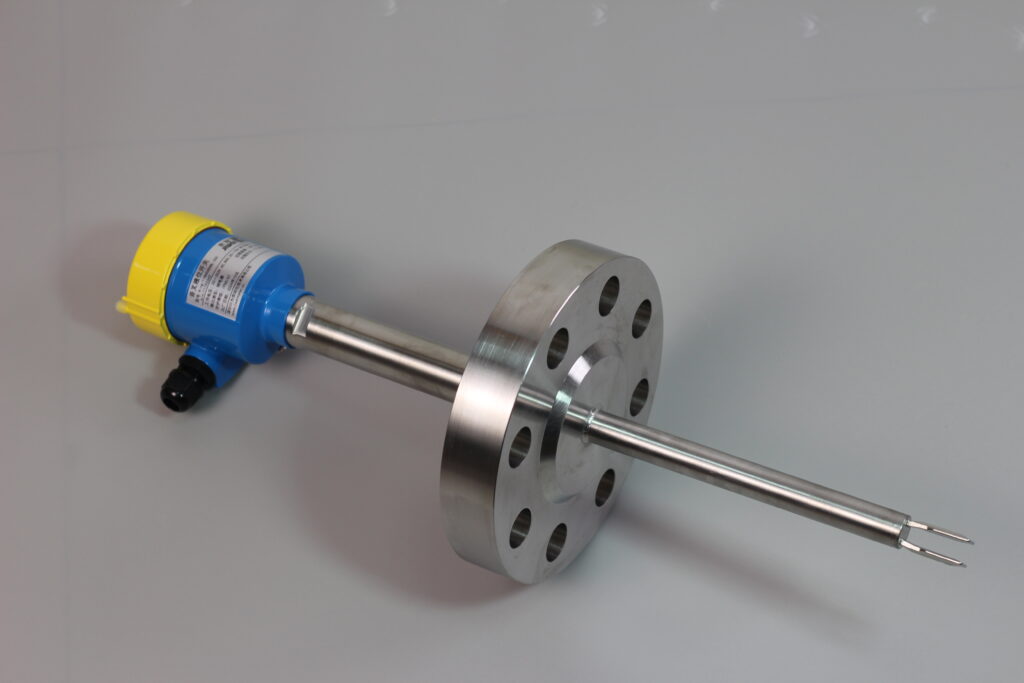

Ring-11 Vibrating Level Switch

The Ring-11 Vibrating Level Switch is designed for precise high and low point-level detection in hydraulic oil reservoir tanks. Unlike traditional tuning fork sensors, it features a ring-shaped vibrating probe that detects media presence by measuring frequency shifts. This unique design minimizes the risk of buildup or false triggering, making it an ideal solution even in tanks with contaminated or aging oil.

Key Features:

- Compact 40mm probe: Perfect for small or space-constrained tanks, the Ring-11’s probe can be easily integrated into existing systems.

- Immune to foam and viscosity changes: The Ring-11 operates effectively even in foamy or viscous oil environments, ensuring reliable readings.

- No calibration required: Once installed, it provides zero maintenance and reliable performance over time.

- Wide temperature range: It can withstand temperatures from -40 to +280°C, making it versatile in extreme environments.

- SIL2/SIL3 certification: Available for safety-critical applications, ensuring compliance with the highest safety standards.

- High sensitivity and fast response: Ideal for detecting point-levels for dry-run protection or overflow alarms.

The Ring-11 is designed to deliver precise and reliable results, whether it is installed at the bottom of the tank for dry-run protection or at the top to monitor overflow conditions.hydraulic oil reservoir tanks

Why Jiwei’s Solutions Stand Out

Jiwei’s level measurement solutions are engineered to provide reliable operation in real-world conditions. Here’s why Rada-31 and Ring-11 are standout options for hydraulic oil reservoir tanks:

- Effective in varying oil compositions: Both devices are capable of handling changes in oil properties, ensuring consistent performance.

- Resistance to interference: Foam, vapor, and viscosity changes are not an issue, making both devices perfect for challenging environments.

- Compact installation options: The devices are designed to fit into space-constrained systems, allowing for easy installation in small tanks.

- Maintenance-free operation: Both solutions are designed to operate with minimal intervention, providing long-term reliability.

- Safety certifications: With SIL2/SIL3 certification and explosion-proof options, these devices meet the safety requirements of critical applications.

By combining the Rada-31 for continuous monitoring and the Ring-11 for precise point-level detection, Jiwei provides a comprehensive solution for efficient hydraulic oil management, ensuring both reliability and safety.hydraulic oil reservoir tanks

Final Thoughts

For industries where hydraulic oil level measurement is crucial, Jiwei offers top-tier solutions with the Rada-31 radar level meter and Ring-11 vibrating level switch. With their advanced technology, zero-maintenance operation, and adaptability to varying oil compositions, these devices provide the accuracy and reliability needed to keep hydraulic systems running smoothly.

These solutions are ideal for industries such as manufacturing, automotive, and power generation, where maintaining optimal hydraulic oil levels is essential for equipment protection and system efficiency. Jiwei’s products enable businesses to reduce downtime, prevent costly repairs, and ensure continuous operation of critical hydraulic systems. hydraulic oil reservoir tanks

FAQs for Hydraulic Oil Level Measurement

1. How does the Rada-31 radar level meter improve hydraulic oil monitoring?

The Rada-31 provides non-contact measurement, which is ideal for varying oil compositions in hydraulic systems. It remains unaffected by foam, vapor, or surface agitation, ensuring accurate level readings in challenging conditions.

2. What makes the Ring-11 vibrating level switch suitable for hydraulic oil reservoirs?

The Ring-11 offers high sensitivity and quick response for point-level detection, ensuring accurate overflow or dry-run protection. Its immunity to foam and viscosity changes makes it an excellent choice for hydraulic oil monitoring.