Explosion-Proof Instruments: Essential Safety Solutions for Flammable and Explosive Environments

Explosion-Proof Instruments Play a Vital Role in Flammable and Explosive Production Areas

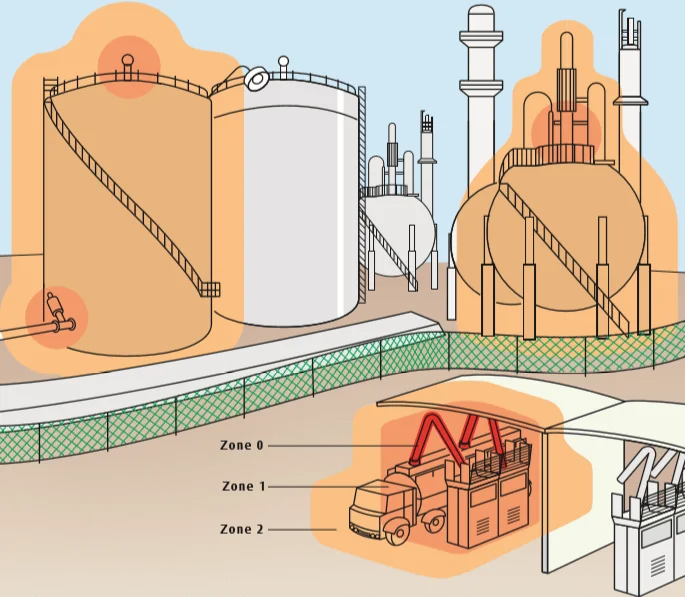

In production environments where flammable and explosive substances are present, explosion-proof instruments are not just a technical necessity but a critical part of safety management. Instrument operation in such areas is not only a highly technical task but also one that carries significant risk. Therefore, to ensure personnel safety and maintain stable equipment performance, it is essential to strictly follow operational protocols. Whether it’s maintenance personnel, instrument technicians, or production line operators, everyone must fully understand the hazard level and relevant explosion-proof standards of the area before entering, ensuring all actions stay within the designated safety boundaries.

Understanding the Fundamental Safety Requirements

Before entering a hazardous area, operators must clearly understand the area’s level of danger and its explosion-proof requirements to minimize the risk of ignition caused by electrical sparks or heat sources.

Proper personal protective equipment (PPE) is mandatory. This includes flame-resistant clothing, anti-static safety boots, hard hats, and protective goggles, all designed to reduce injury risks from sparks or explosions.

Lone work is prohibited. Instrument operation in explosive environments should always involve at least two people—one performing the task and another on standby for monitoring. This ensures rapid response in the event of an emergency.

Standard Procedures for Instrument Operation Explosion-Proof Instrument

Communication is essential. Always inform and coordinate with process personnel before handling any instrument maintenance or troubleshooting, to avoid unnecessary disruption or conflict.

When dealing with instruments integrated into interlock systems, switch them to manual mode and disable the interlock before performing any maintenance. This prevents unintended process interruptions or safety risks due to false triggering.

Use only certified explosion-proof tools. Avoid using spark-generating tools such as steel hammers or other striking instruments.

Follow proper installation and removal procedures. Never attempt to dismantle instruments like level transmitters or pressure gauges while under pressure. Rushing such tasks may lead to serious accidents.

Electrical Safety Considerations

Electrical safety must never be overlooked. All lighting equipment used in hazardous areas must be explosion-proof certified to prevent ignition caused by electrical sparks.

Power and signal cable connections must follow strict sealing and installation standards to prevent flammable gases from entering instrumentation housings.

All automation instruments and electrical equipment must be properly grounded. In the event of a leakage, grounding ensures power is quickly cut off to avoid ignition. Regular insulation checks are also necessary to ensure equipment remains in safe operating condition. Remember the rule: secure grounding, and routine insulation testing—no exceptions.

Special Work Requirements in Hazardous Areas

Hot work operations (e.g., welding, grinding) must be approved through the appropriate work permit system. Only after gas analysis confirms safety can personnel enter the site, and designated personnel must monitor gas concentrations throughout the task.

For high-temperature work, operators must wear thermal protective gear, and insulation barriers should be placed around the work area to prevent burns or heat-related injuries.

Working at heights near flammable equipment or piping requires prior isolation—closing valves or pressure taps—and wearing certified fall protection gear at all times.

Other Precautions for Instrument Safety

Regular inspection and maintenance of all instrumentation are essential. Any anomalies must be addressed immediately to prevent potential hazards from escalating.

Smoking and open flames are strictly prohibited. Flammable and explosive materials must never be brought into the working area.

All operations must strictly follow established safety procedures. Any deviation can lead to severe consequences, including fire, explosion, or personal injury.

Explosion-Proof Instrument Solutions by Jiwei Automation

With years of expertise in level measurement technologies, Shenzhen Jiwei Automation has developed a range of independently designed explosion-proof instruments, all certified by the Tianjin Explosion-Proof Institute and compliant with strict explosion-proof standards.

Jiwei’s explosion-Proof Instruments includes vibrating rod level switches, tuning fork level switches, tuning fork liquid level switches, reed switch-based remote transmitters, magnetic switches, and float level transmitters, available in both flameproof (Ex d) and intrinsically safe (Ex ia) versions to meet the demands of various hazardous environments. Additionally, ultrasonic level transmitters and rotary paddle level switches are available with flameproof designs.

Of course, even the most advanced instruments cannot compensate for improper handling. Unsafe operation can still lead to serious safety hazards. Therefore, operators must rigorously follow all outlined safety guidelines, continuously strengthen safety awareness, and undergo regular safety training to ensure safe and reliable use of explosion-proof instrumentation.