Tank Level Measurement: Maximize Efficiency with 5 High-Performance Solutions

Introduction

In industrial processes, accurate and reliable tank level measurement is crucial for ensuring smooth operations, minimizing waste, and maintaining safety. Different measurement technologies, including tuning fork level switches, float level meters, magnetic level meters, ultrasonic level meters, and radar level meters, offer distinct advantages based on application needs. This article explores five popular tank level measurement solutions, highlighting the benefits of Jiwei’s cutting-edge products.

1. Tuning Fork Level Switches (Ring-11)

Tuning fork level switches, such as Jiwei’s Ring-11, provide highly reliable tank level measurement in tanks containing a variety of materials, from solids to liquids. These devices work by detecting changes in vibration frequency as the material contacts the fork.

Advantages:

- High reliability in both solid and liquid’s tank level measurement

- Minimal maintenance due to no moving parts

- Ideal for corrosive and hazardous materials

- Corrosion-resistant option with Hastelloy C-22 material for high-temperature environments

- Certified for SIL2/SIL3 compliance, Intrinsic Safety, and Explosion-Proof protection

Applications:

- Ideal for use in tanks with challenging substances, such as chemicals or high-viscosity liquids.

2. Float Level Meters (Float-11)

Float level meters are widely used in tanks where liquid levels need to be measured accurately over long ranges. The float moves in response to changes in the liquid level, triggering a sensor that transmits the data.

Advantages:

- Cost-effective for many tank level measurement of liquid

- Easy installation and calibration

- Highly versatile with different float materials for various densities

- Certified for flameproof and intrinsic safety for hazardous areas

Applications:

- Used in applications ranging from water treatment tanks to oil storage.

3. Magnetic Level Meters (Flap-11)

Magnetic level meters, such as Jiwei’s Magnetic Level Meter, provide accurate, non-invasive level measurement. As the material level changes, the internal float moves, activating a magnet that triggers an external flap indicator.

Advantages:

- Durable and corrosion-resistant

- Clear visual indication of level with a broader viewing angle

- Explosion-proof designs available for hazardous materials

- SIL2/SIL3 certified and complies with IEC 61508 standards

Applications:

- Widely used in the chemical, petroleum, and food industries.

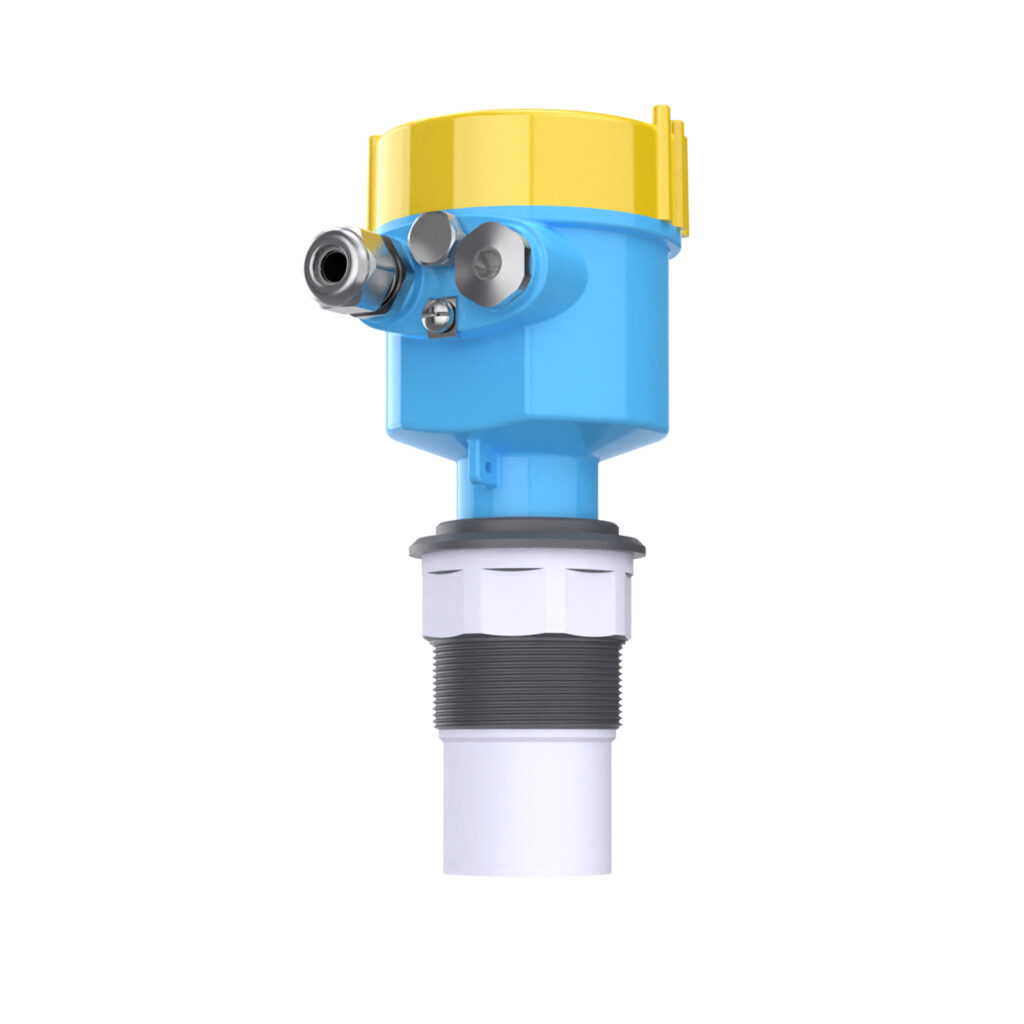

4. Ultrasonic Level Meters (Uson)

Ultrasonic level meters, such as Jiwei’s advanced ultrasonic series, use high-frequency sound waves to measure the distance between the sensor and the material surface. These devices are ideal for non-contact level measurement.

Advantages:

- No physical contact with the material, reducing wear and tear

- Accurate over long measurement ranges

- Temperature compensation for high adaptability

- RS-485 interface for real-time monitoring

- IP66/IP67 ingress protection rating

Applications:

- Suitable for liquids and solids, including foam or steam-filled tanks.

5. Radar Level Meters (Rada-31)

Radar level meters are known for their high precision and ability to measure in extreme conditions, such as high temperatures, pressure, and vapor. Jiwei’s 80Hz radar level meters offer robust performance in demanding environments.

Advantages:

- High accuracy with 80GHz radar technology and narrow beam angle

- Non-contact measurement for minimal wear

- Stable performance in harsh conditions like dust, steam, and temperature fluctuations

- Built-in Bluetooth for wireless connectivity and easy setup

- Strong adaptability to narrow pipelines and challenging installations

Applications:

- Perfect for industries like mining, cement, and oil & gas.

Comparison Table:

| Measurement Technology | Ideal for | Advantages | Applications |

|---|---|---|---|

| Tuning Fork Level Switch | Solids and liquids | High reliability, minimal maintenance | Chemicals, hazardous liquids |

| Float Level Meter | Liquids | Cost-effective, easy installation | Water, oil storage |

| Magnetic Level Meter | Liquids | Durable, explosion-proof, clear visual indication | Chemical, petroleum, food industries |

| Ultrasonic Level Meter | Liquids & solids | Non-contact, long-range measurement | Foam, steam, water tanks |

| Radar Level Meter | Liquids & solids | Precise in extreme conditions | Cement, mining, oil & gas |

Conclusion

Selecting the right tank level measurement technology is essential for ensuring operational efficiency and safety. Jiwei’s range of products, including the Ring-11 tuning fork level switch, Float-11 float level meters, Magnetic Level Meters, ultrasonic level meters, and 80Hz radar level meters, offer optimal solutions for various industrial applications. Whether dealing with hazardous materials, large tanks, or extreme environmental conditions, Jiwei’s advanced technologies ensure accurate, reliable level measurement.

For more information on how Jiwei’s products can optimize your tank level measurement processes, explore our comprehensive solutions today.