7 Common Types of Level Switches

Point level switches are designed to indicate a specific high or low level of material.Continuous level switches provide real-time level monitoring and detection.Ultrasonic level switches use sound waves to measure the distance to the material surface.Capacitance level switches detect levels by measuring changes in capacitance created by the presence of material. Conductivity level switches are ideal for detecting the presence or absence of a conductive liquid.

1. Float Level Switches

- Description: Utilizes a floating component that rises and falls with the liquid level.

- Applications: Water tanks, sumps, oil tanks.

- Advantages: Simple, reliable, and cost-effective.

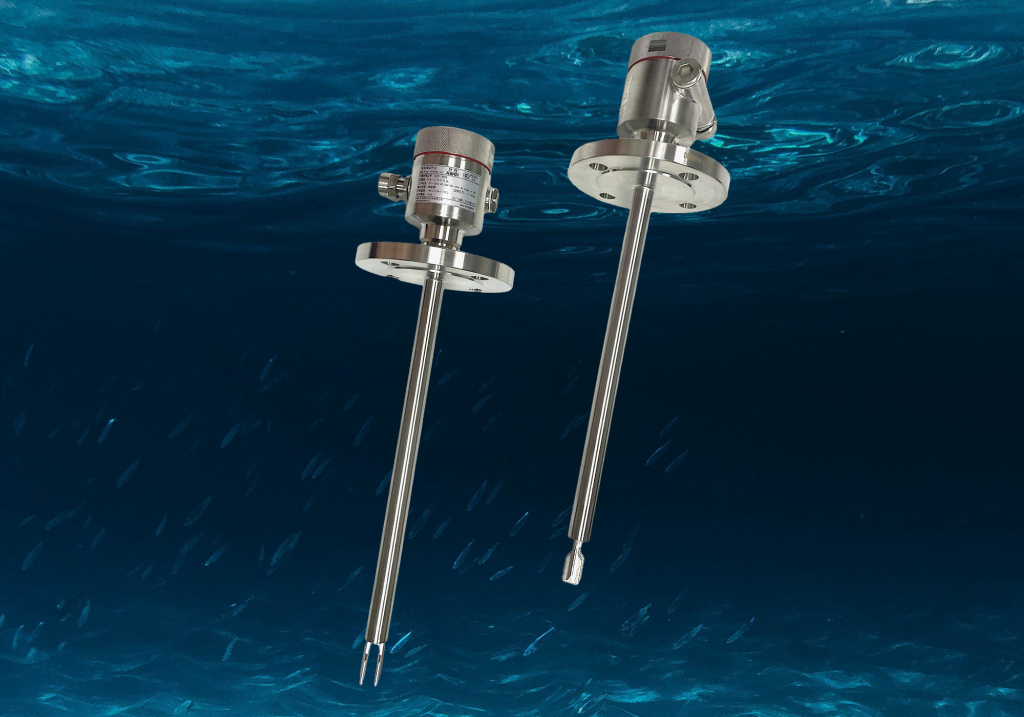

2. Tuning Fork Level Switches

- Description: Uses a vibrating fork that changes frequency when immersed in a liquid or solid.

- Applications: Powders, granules, liquids.

- Advantages: Not affected by changes in conductivity, density, pressure, or temperature.

3. Capacitance Level Switches

- Description: Measures changes in capacitance caused by the presence or absence of a material.

- Applications: Solids, liquids, slurries.

- Advantages: No moving parts, can be used in harsh environments.

4. Vibrating Rod Level Switches

- Description: Similar to tuning fork switches but uses a single rod that vibrates.

- Applications: Powders, granular materials.

- Advantages: Reliable and unaffected by material buildup.

5. Magnetic Level Switches

- Description: Uses a magnetic float and reed switch to detect the liquid level.

- Applications: Fuel tanks, hydraulic systems.

- Advantages: Durable and suitable for high-pressure applications.

6. Pressure Level Switches

- Description: Measures the pressure exerted by a liquid column to determine the level.

- Applications: Deep wells, tanks with varying densities.

- Advantages: Can measure very high levels.

7. Radar Level Switches

- Description: Uses microwave radar pulses to measure the level of a material.

- Applications: Liquids, solids, in harsh environments.

- Advantages: Accurate, non-contact measurement, works in extreme conditions.

Conclusion

Types of Level Switches,in addition to Ultrasonic Level Switches, Microwave Level Switches, and Laser Level Switches, Conductive Level Switches and Optical Level Switches are commonly employed in various industries to detect material levels with precision and reliability. Conductive Level Switches operate based on the material’s conductivity, while Optical Level Switches are advantageous for detecting transparent liquids in hygienic environments like the food and beverage sector.