Henkel 6253 Glue: Ensuring Precision in Liquid Level Measurement

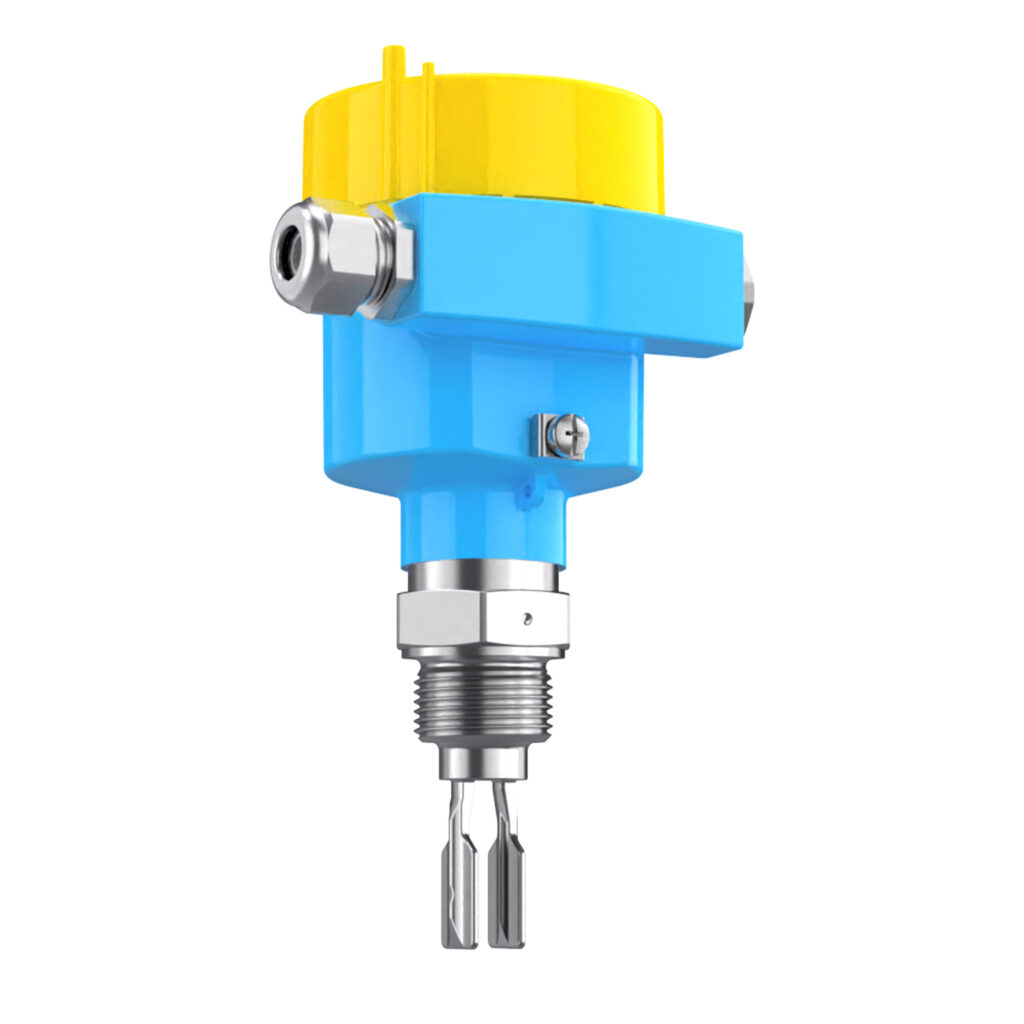

When it comes to liquid level measurement for challenging materials like Henkel 6253 glue, accuracy, reliability, and cost-efficiency are key considerations. For industries using this type of adhesive, precision in level monitoring ensures both safety and operational effectiveness. This is where the Ring-11 tuning fork level switch by Jiwei stands out as a powerful solution, offering a range of benefits for liquid level measurement in critical processes.

Understanding the Challenges of Measuring Henkel 6253 Glue

Henkel 6253 glue, a highly viscous material, is commonly used in industrial applications, including automotive manufacturing and electronics assembly. Due to its thick and sticky consistency, measuring the liquid level can be particularly challenging. Traditional methods such as float-based or capacitive sensors often struggle with reliability when faced with thick adhesives that can coat sensors or affect readings. This makes it essential to choose the right level switch to ensure accurate measurements without constant maintenance or recalibration.

Why Choose the Ring-11 Tuning Fork Level Switch?

The Ring-11 tuning fork level switch from Jiwei provides a solution specifically designed for such demanding environments. Here’s how it meets the needs of liquid level measurement in materials like Henkel 6253 glue:

1. Precise and Reliable Operation

The Ring-11 offers precise and reliable operation, even with materials as difficult to measure as Henkel 6253 glue. With its product-independent switching point, this device ensures consistent performance across different materials, regardless of viscosity. The tuning fork mechanism is immune to the issues that often affect other types of level switches, like coating or build-up, providing accurate readings every time.

2. Minimal Setup Time and Cost

One of the standout features of the Ring-11 is its simple setup that doesn’t require special media or additional complex configurations. This drastically reduces both time and cost investment, making it a cost-effective solution for industries where downtime is expensive. Installation is straightforward, saving businesses both initial setup costs and long-term maintenance costs.

3. Modularized Electronic Components for Easy Maintenance

The Ring-11 tuning fork level switch is designed with modular electronic components that simplify maintenance. If any part of the switch needs servicing, it’s easier to replace or repair individual modules, reducing overall maintenance time and costs. This is especially important in industries that rely on uninterrupted production, such as those using Henkel 6253 glue, where consistent material flow is essential.

4. Durability in Harsh Environments

With an ECTFE and PFA-coated high-temperature extension tube, the Ring-11 is built to withstand harsh operating conditions. These coatings provide enhanced durability, ensuring that the switch performs reliably even when exposed to aggressive chemicals or high temperatures, making it perfect for the production lines where Henkel 6253 glue is used.

5. Versatile Output Options

The Ring-11 is designed to integrate seamlessly into a variety of systems. It supports multiple output options, including relay, transistor, two-wire, and NAMUR, making it adaptable to different control systems. This versatility ensures that it can be easily incorporated into existing processes, offering the flexibility needed for diverse industrial environments.

6. Safety and Compliance with IEC 61508 for SIL2/SIL3 Applications

For industries that require the highest safety standards, such as those working with hazardous or volatile materials, the Ring-11 is developed according to IEC 61508 standards. It is specifically designed for SIL2 and SIL3 applications, which are critical for ensuring safe operations in high-risk environments. This compliance offers peace of mind, knowing that the system meets rigorous safety and reliability standards.

7. CE Certification for European Safety Standards

The Ring-11 is CE certified, confirming its compliance with European safety standards. This certification ensures that the level switch meets essential health, safety, and environmental protection requirements, making it suitable for use in various international markets.

The Bottom Line: Reliable Liquid Level Measurement for Henkel 6253 Glue

The Ring-11 tuning fork level switch from Jiwei provides a superior solution for liquid level measurement in industries using Henkel 6253 glue. Its precision, durability, and ease of maintenance make it an excellent choice for process industries where reliability and safety are paramount. Whether you’re monitoring adhesives in automotive manufacturing or electronics assembly, the Ring-11 ensures that you achieve accurate measurements without the hassle of frequent recalibration or system downtime.

By choosing Jiwei’s Ring-11, you not only ensure accurate liquid level monitoring but also contribute to the long-term efficiency and safety of your production processes. It’s time to invest in reliable, cost-effective, and safe level measurement with Jiwei’s Ring-11 tuning fork level switch.