Avoid Risks: Level Measurement in Anhydrous Ammonia Storage Tanks

The storage and handling of anhydrous ammonia are critical processes in industries like fertilizer production, where the need for safe and efficient ammonia management is paramount. As ammonia is a hazardous substance, maintaining precise control over its levels in storage tanks is essential to avoid accidents, comply with regulations, and ensure smooth operations.

Challenges in Anhydrous Ammonia Storage

Anhydrous ammonia, a colorless and highly corrosive gas under standard conditions, transforms into a liquid when temperatures drop below -33.3°C (-27.94°F) or at higher pressures. In storage tanks, it is usually kept as a liquid under these conditions. Given the volatile nature of ammonia, the accurate measurement and continuous monitoring of ammonia levels are crucial for preventing overfills, leaks, and potential safety hazards.

Ammonia is produced during processes such as nitrogen conversion through water wash for fertilizer manufacturing. In these processes, maintaining proper ammonia levels in the storage tanks is critical not only for product consistency but also for meeting environmental regulations.

Why Accurate Level Measurement in Anhydrous Ammonia Storage Tanks is Crucial

Accurate level measurement in anhydrous ammonia storage tanks is vital for preventing hazardous overflows, tank ruptures, or underfilling, all of which can lead to operational inefficiencies or safety breaches. Moreover, effective level measurement helps ensure ammonia is available when needed, preventing disruptions in the production cycle. The importance of precise level monitoring is underscored by stringent safety and environmental regulations that demand continuous control.

Inadequate monitoring of ammonia levels can also result in equipment failure, environmental contamination, and even costly shutdowns. By ensuring the correct levels, businesses can avoid unnecessary repairs, minimize operational downtime, and maintain regulatory compliance.

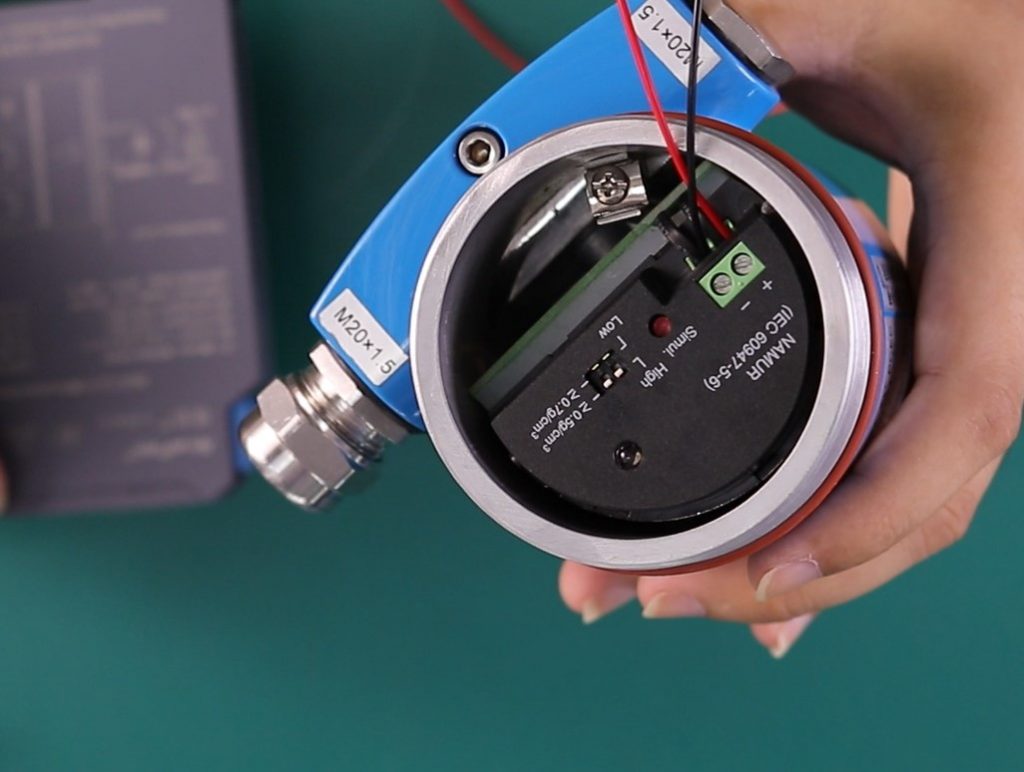

The Role of Jiwei’s Tuning Fork Level Switch

To address the challenges of level detection in anhydrous ammonia storage tanks, Jiwei’s Vibrating Fork Level Switch provides an effective and reliable solution. This device offers point level detection, ensuring that the ammonia storage tank’s level is continuously monitored with high accuracy.

The Jiwei tuning fork level switch operates on the principle of resonance frequency. When the tank is empty or contains no liquid, the switch vibrates at its natural frequency. However, when ammonia fills the tank, the liquid alters the switch’s vibration frequency, triggering an alert. This change is immediately detected, enabling real-time monitoring and automatic responses to prevent overfilling or underfilling.

Why Choose Jiwei’s Vibrating Fork Level Switch?

Jiwei’s Vibrating Fork Level Switch offers several advantages for anhydrous ammonia storage tanks:

- Accurate Level Detection: The tuning fork level switch provides precise level detection even in harsh ammonia storage environments, ensuring continuous monitoring without compromise.

- Fail-Safe Operation: With its resonance frequency design, the level switch offers fail-safe operation, ensuring reliable performance even in extreme conditions, which is crucial for the hazardous ammonia storage process.

- Corrosion Resistance: Built to withstand aggressive chemicals, Jiwei’s level switch is made from corrosion-resistant materials, making it ideal for use in ammonia storage tanks, where environmental exposure is inevitable.

- Simple Installation: The Jiwei level switch is designed for easy installation at low points in ammonia storage tanks, providing versatility for various tank configurations.

- SIL2/SIL3 Certification: Jiwei’s tuning fork level switch meets SIL2/SIL3 safety standards, ensuring it’s fit for use in critical applications that require high reliability and safety.

Additional Features of Jiwei’s Tuning Fork Level Switch

- Minimal Maintenance: With no moving parts, Jiwei’s level switch requires minimal maintenance, reducing long-term operational costs.

- Wide Temperature Range: Designed for use in extreme temperatures, the switch can perform in ammonia storage tanks that operate at low temperatures as low as -33.3°C, making it suitable for such harsh environments.

- High Sensitivity: The level switch provides high sensitivity to detect even small changes in liquid levels, allowing for early detection of potential issues.

- Versatile Output Options: Jiwei’s level switch offers multiple output configurations, including relay, two-wire, NAMUR and transistor outputs, making integration into existing control systems straightforward.

Best Practices for Anhydrous Ammonia Storage Tank Level Measurement

For optimal performance of the Jiwei tuning fork level switch, consider the following best practices:

- Proper Placement: Install the level switch at the lowest point of the storage tank where ammonia typically collects to ensure accurate detection.

- Regular Calibration: While the Jiwei tuning fork switch requires minimal maintenance, regular calibration checks are essential to ensure the system is functioning correctly.

- Test Functionality: Periodically test the system’s function to verify its reliability and accuracy. This proactive approach helps detect any issues early on.

Conclusion

Accurate level measurement in anhydrous ammonia storage tanks is vital to maintaining safety and efficiency in the handling and storage of ammonia. With its hazardous properties, ammonia demands constant monitoring to prevent accidents, environmental risks, and costly downtime. Jiwei’s Vibrating Fork Level Switch offers a reliable, fail-safe solution to meet these needs.

By providing accurate and continuous monitoring of ammonia levels, Jiwei’s tuning fork level switch ensures that ammonia storage operations run smoothly, safely, and efficiently. With its corrosion resistance, high sensitivity, and SIL2/SIL3 certification, it is the ideal solution for anhydrous ammonia storage tank applications.

Ensure the safety of your anhydrous ammonia storage tanks—choose Jiwei’s vibrating fork level switch for precise and reliable level detection today.