Cement Silo Level Detection: Reliable Solutions for Accurate Monitoring

Cement silos are critical for storing cement and other materials in the construction industry. Proper level monitoring in cement silos is essential for efficient inventory management, preventing overflows, and minimizing material wastage. As cement is often dense and powdery, measuring its level within the silo can be challenging. This article will discuss the best level detection technologies for cement silos, including vibrating rod level switches, tuning fork level switches, and rotary level switches. These solutions ensure accurate and real-time monitoring of cement levels, boosting operational efficiency.

The Importance of Cement Silo Level Monitoring

Effective cement silo level monitoring is crucial for:

- Preventing Overflows and Spills: Accurate measurement helps avoid overfilling, preventing costly spills and environmental issues.

- Optimizing Inventory Management: Real-time level measurement ensures proper tracking of material levels, optimizing storage and reducing stockouts.

- Ensuring Safety: Monitoring cement levels prevents equipment malfunctions and failures due to excessive material buildup, ensuring the safety of workers and machinery.

- Reducing Waste: Proper measurement guarantees efficient use of materials, minimizing waste during loading and unloading.

Effective Cement Silo Level Detection Technologies

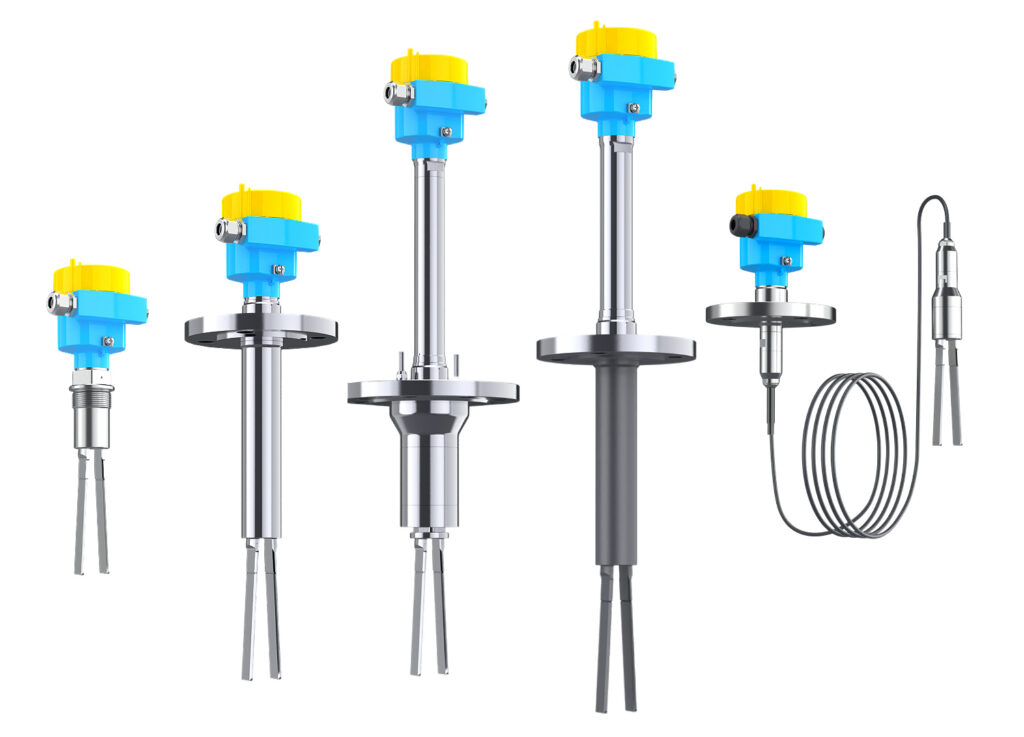

1. Vibrating Rod Level Switches

Vibrating rod level switches are ideal for high-density, granular materials like cement. These devices work based on vibration frequency. When the vibrating rod comes into contact with the material, the vibration frequency changes, triggering an alarm. These switches are reliable, accurate, and require minimal maintenance.

Key Features:

- Suitable for dense granular materials like cement

- High temperature tolerance up to 400°C

- Point, precise level monitoring

2. Tuning Fork Level Switches

Tuning fork level switches are excellent for powdery materials like cement. These switches use resonance principles to detect level changes. When the material touches the fork, the vibration frequency shifts, indicating a level change. The tuning fork design offers stability and accuracy, even in vibrating environments.

Key Features:

- Ideal for powdery or bulk materials

- Reliable performance in dusty conditions

- Temperature tolerance up to 400°C

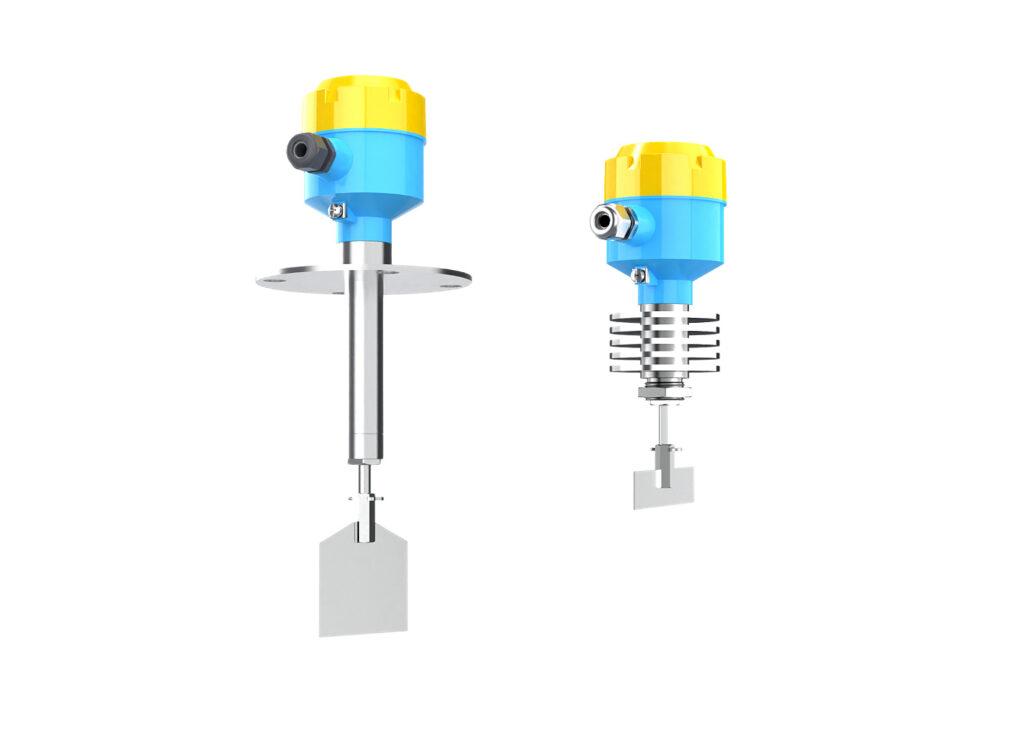

3. Rotary Level Switches

Rotary level switches are used for point level detection, particularly in bulk solids like cement. The device uses a rotating vane that is activated when material reaches the vane, signaling a level change. These switches are durable and perform well in harsh environments, ensuring proper material level monitoring.

Key Features:

- Provides point level detection for bulk solids

- High temperature resistance up to 400°C

- Reliable in harsh industrial environments

Choosing the Right Level Detection Technology for Cement Silos

Selecting the appropriate level detection technology depends on the cement silo’s specific requirements, such as material type, environmental conditions, and whether continuous or point-level monitoring is needed. Below is a comparison of the three technologies mentioned above.

| Technology | Best for | Features | Max Temperature |

|---|---|---|---|

| Vibrating Rod Level Switch | High-density granular materials | Point level detection, low maintenance | 400°C |

| Tuning Fork Level Switch | Powdery or bulk materials | Resonance-based detection, high precision | 400°C |

| Rotary Level Switch | Point-level detection for bulk solids | Reliable in harsh environments, point detection | 400°C |

Why Choose Our Products?

Our vibrating rod, tuning fork, and rotary level switches offer precise and reliable cement silo level monitoring. With over 50 patents and cutting-edge technology, our products are trusted worldwide. These devices can withstand extreme temperatures (up to 400°C) and provide accurate results in the most challenging environments.

Conclusion

Choosing the correct level detection technology for your cement silo is essential for optimizing material handling and maintaining operational efficiency. Vibrating rod, tuning fork, and rotary level switches are ideal solutions for accurate and reliable cement level monitoring. By investing in the right technology, you can prevent overflows, reduce waste, and enhance safety in your cement storage operations.