Dielectric Constant: The Underrated Physical Variable Behind Industrial Automation

In the era of “smart manufacturing,” “Industry 4.0,” and “intelligent automation,” digital transformation has become the buzzword across the industrial landscape. From cloud-connected SCADA systems to AI-powered analytics and 5G-enabled machine communication, the narrative often suggests that deploying a few sensors and connecting them to the cloud is enough to transform a traditional factory into a futuristic smart plant.

But those who have truly been involved in engineering projects know the reality: the success and stability of these systems often hinge not on software, protocols, or platforms—but on something far more fundamental and often overlooked in digital discussions: physics.

Among the most critical, yet underestimated, physical parameters in automation is the dielectric constant.

1. Why the Dielectric Constant is the “Foundation Parameter” in Automation

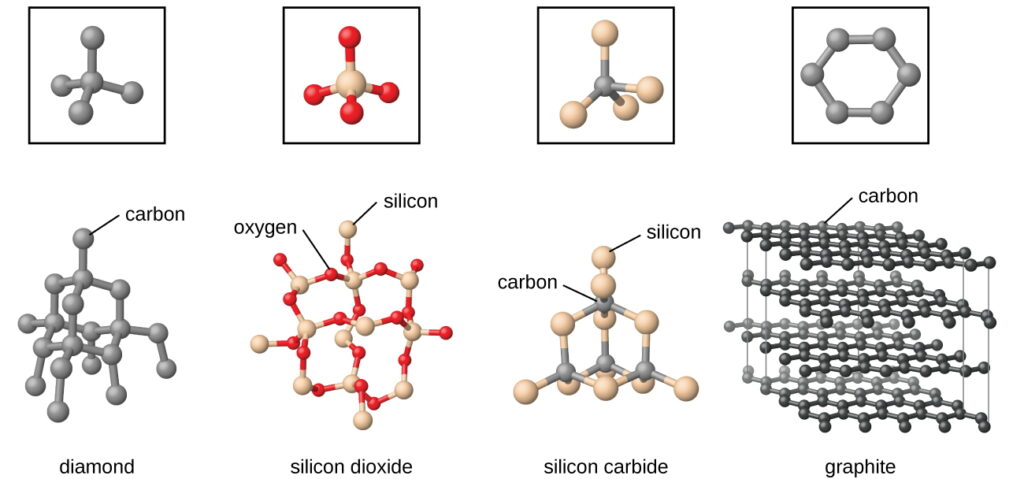

The dielectric constant (εr)—a measure of how a material interacts with an electric field—is typically covered in basic materials science courses. But in real-world automation systems, this single variable often determines the difference between stable operation and inexplicable system failures.

It directly affects:

- Electromagnetic signal transmission

- Capacitive and radar level measurements

- Sensor response accuracy

- EMC/EMI resilience in harsh environments

A mismatch or drift in dielectric constant—due to temperature variation, material change, or incorrect material choice—can result in issues such as signal attenuation, delayed response, measurement drift, or system malfunction.

To put it simply:

Dielectric instability = signal distortion = unreliable automation.

2. The Dielectric Constant: The Invisible Hand of Sensing and Measurement

Unlike many static physical constants, the dielectric constant is dynamic and context-sensitive. It changes with temperature, frequency, pressure, humidity, and material composition—making it a critical factor in measurement instruments and process control.

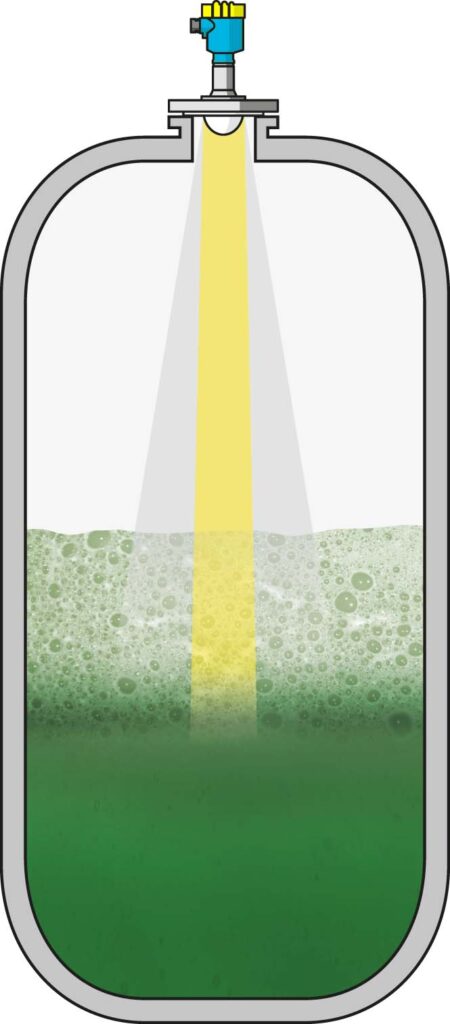

• Radar Level Transmitters: Echo Strength Depends on εr

Radar level instruments rely on the reflection of electromagnetic waves. The strength and clarity of the return signal are directly proportional to the dielectric constant of the target medium.

- Low-εr liquids (e.g., hydrocarbons) yield weak reflections, causing signal loss or misjudgment.

- High-εr liquids (e.g., water, acids) provide strong reflections but are susceptible to fluctuation due to foam, vapor, or mixing phases.

Real-time dielectric compensation is essential in these cases, requiring not just hardware adaptation, but frequency tuning algorithms to match signal wavelength with the material’s εr profile.

• Capacitive Level Sensors: Measurement Accuracy Tied to Material Permittivity

Capacitive level sensors infer material level based on capacitance, which is intrinsically dependent on the dielectric constant of the material.

- Dry powders or granules (low εr) may produce signals too weak to detect reliably.

- Moist or dense materials (high εr) may cause excessive sensitivity, leading to overestimation or false alarms.

An effective solution involves dielectric characterization modeling and adaptive threshold calibration to account for the expected material variation.

• Electromagnetic Flow Meters: Signal Stability Influenced by εr Fluctuation

EM flow meters detect flow rates based on induced voltage from conductive fluids moving through a magnetic field. However, dielectric properties of the fluid affect the field interaction and signal fidelity.

- Bubbly or mixed-phase fluids lead to dielectric shifts and signal instability.

- In slurries or high-solid-content fluids, spatial εr variation adds complexity, making compensation challenging.

Modern systems require real-time dielectric tracking algorithms coupled with intelligent signal filtering to correct for such distortions.

• Humidity Sensing: εr as a Direct Indicator of Water Content

Dielectric-based humidity sensors operate by observing changes in permittivity as materials absorb water. While widely used, achieving high precision requires factoring in:

- Temperature and pressure compensation

- Spectral separation of bound vs. free water

- Non-linear behavior under dynamic environments

Rather than treating dielectric behavior as a nuisance, leading systems now interpret it as a rich, multi-dimensional signal source.

3. True Engineering Begins at the Physical Layer

The increasing complexity of automation systems demands more than modular system design or plug-and-play integration. Many system instabilities today are rooted in shallow physical understanding—engineers relying solely on component datasheets without fully appreciating the electromagnetic and material-level interactions at play.

Future industrial design trends will demand deeper synergy between physical-layer parameters and control-layer intelligence. And dielectric constant is at the center of this shift.

It will drive innovation in three key directions:

- Material Design: Tailored multi-phase materials with engineered permittivity for sensor miniaturization and stability.

- Intelligent Sensing: AI-enhanced physical modeling that treats dielectric variation as a core signal—not noise.

- Physics-Integrated Engineering: Designers who can not only read datasheets, but also interpret dielectric spectra, field distribution, and permittivity response.

Conclusion: Building the Future Requires Understanding the Fundamentals

Today’s automation industry resembles the early days of industrial steelmaking: competitive on the surface through scale and speed, but fundamentally driven by those who understand and control the physical laws underneath the system.

The dielectric constant, far from being a textbook relic, is the foundation of stable and intelligent industrial systems. Ignore it, and even the most advanced automation stack may collapse under its own complexity.

In the age of smart automation, those who go deeper into physics will build systems that go higher in performance.