Fork-11 High-Temperature Tuning Fork Level Switch

Fork-11 High-Temperature Tuning Fork Level Switch is designed specifically for high process temperatures up to 250°C (482°F).

The Fork-11 High-Temperature Tuning Fork Level Switch is engineered for high process temperatures up to 250°C (482°F). It incorporates a unique design that prevents material bridging and buildup on the sensor.

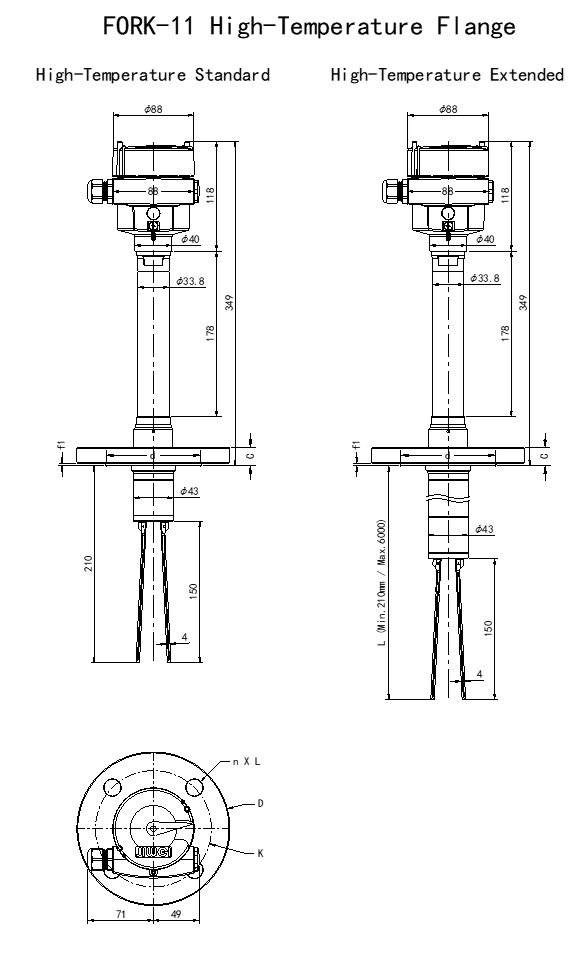

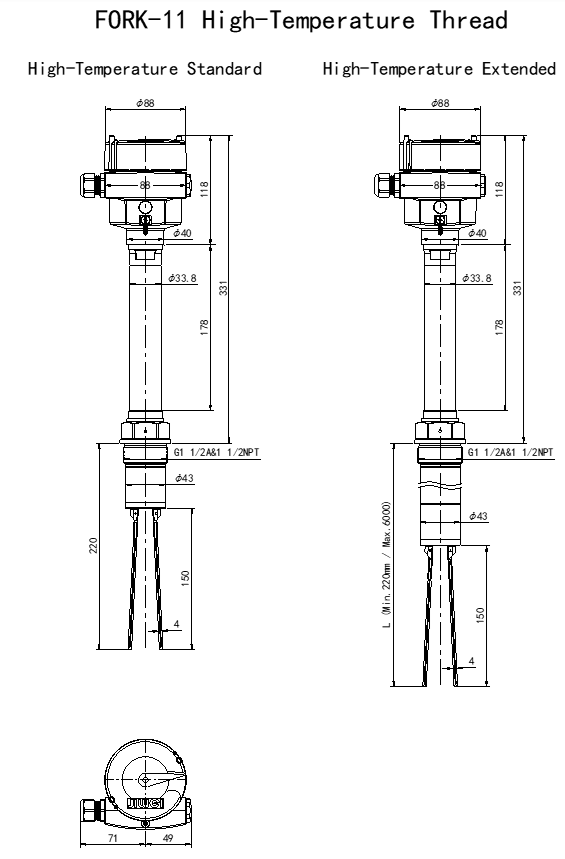

Based on the standard Fork-11 model, the high-temperature version includes an extension tube between the housing and process connection, along with temperature-resistant piezoelectric components and wiring. This model is ideal for high and low-level detection of powdery and fine-grained bulk solids, with densities as low as 0.008g/cm³, even at temperatures up to 250°C (482°F). The extension tube increases the instrument’s overall size for improved performance in extreme conditions.

The Fork-11 High-Temperature Tuning Fork Level Switch operates on the same principle as the Fork-11 series. It uses tuning fork harmonic resonance, driven by piezoelectric devices to generate vibrations and detect changes in vibration patterns.

When the fork is in air, it vibrates at its resonant frequency. Upon contact with the application medium, the vibration amplitude decreases significantly. The piezoelectric device detects this decrease, and an integrated circuit analyzes the reduction to output a switch signal. By optimizing the tine area and fine-tuning the harmonic resonance, the Fork-11 High-Temperature Tuning Fork Level Switch delivers exceptional reliability and sensitivity, making it the ideal choice for ultra-low-density media, even at high temperatures.

● Ideal for high and low-level indication in powdery and fine-grained bulk solids, with densities as low as 0.008g/cm³, even at process temperatures up to 250°C (482°F).

● Advanced self-diagnostic function for precise fault detection and quick troubleshooting.

● Hassle-free installation and maintenance, reducing operational downtime and costs.

● Certified for safety with CE certificates, gas and dust Flameproof Enclosure (Ex db lIC T1…T6 Gb), and Intrinsic Safety certificates (Ex ia II CT1…T6 Ga).

● Durable and corrosion-resistant, made from high-quality 316L stainless steel for long-lasting performance.

● Meets stringent industry standards including FDA, HACCP, and 3A, ensuring safety, hygiene, and reliability for use in food and pharmaceutical applications.

| Applicable medium | Types of the Medium | powders or granular solids |

| Density | ≥0.008 g/cm³ | |

| Medium size | Max. 10mm | |

| Probe data | Vibration frequency | ~140Hz |

| Fork length | 150mm | |

| Switching Delay | When immersed | 0.5s |

| When laid bare | 1s | |

| Power supply | Relay | 20~253V AC/20~72V DC |

| Two-wire | 10~36V DC | |

| Max. power consumption | 8VA(AC);1.5W(DC) | |

| Output | Relay | DPDT, 5A/253V AC/24V DC |

| Two-wire | 8mA/16mA, Alarm <2.3mA | |

| Installation conditions | Process pressure | -1~25bar |

| Process temperature | Regular temperature r: -50~150℃ High temperature: -50~250℃ Ultra-high temperature: -50~400℃ | |

| Ambient temperature | -40~80℃ | |

| Storage and transport temperature | -40~80℃ | |

| Cooling system data (for Ultra-high temperature only) | Air intake tube | 6×4 (Outer diameter 6mm) PU tube |

| Cooling air pressure | 0.8Mpa | |

| Min. cooling air flow rate | To be adjusted | |

| Overvoltage protection | Relay | Category III, class I |

| Two-wire | Category III, class II | |

| Certificates and approvals | Ingress Protection | IP66/IP67 |

| Explosion-Proof | Flameproof Enclosure:: Ex db lIC T1…T6 Gb; Ex tb IIIC T80℃…T440°C Db | |

| Intrinsic Safety: Ex ia II CT1…T6 Ga; Ex ia IIIC T₂₀₀100℃…T₂₀₀450℃ Da | ||

| CE | LVD and EMC Certificates | |

| Materials | Housing | Aluminum alloy, stainless steel |

| Ground terminal | 316L | |

| Process fitting | 316L, 316L coated PTFE | |

| Fork | 316L, 316L coated PTFE | |

| Process seal | Klingersil C-4400 |

● Biopharmaceutical Powder Level Control

Fork-11 is applied in the biopharmaceutical industry to measure powder levels in manufacturing processes, meeting high-temperature, FDA, and HACCP requirements for safety and hygiene.

● Foam Molding Process

Fork-11 measures the level of foam materials in EPP and EPS molding machines, ensuring accurate level detection at high temperatures during the plastic forming process.

● Fumed Silica Level Measurement

Fork-11 is ideal for measuring the level of fumed silica (SiO₂), a highly low-density powder, with a density as low as 0.008g/cm³, ensuring precision in environments with minimal material accumulation.

● Zircon Sand Level Measurement

In high-temperature industrial environments, Fork-11 ensures the precise level measurement of zircon sand used in metal casting processes, preventing overfilling or underfilling in hoppers.

● Petroleum Coke Level Monitoring

Fork-11 is used in petroleum coke production to measure material levels in high-temperature conditions, optimizing material management in refineries.

● Cement Production Dust Level Measurement

In cement plants, Fork-11 measures the level of cement dust in silos and hoppers, ensuring efficient and accurate material handling under extreme conditions.

● Alumina Powder Level Detection

Fork-11 is used to monitor alumina powder levels in aluminum production, preventing overflows and optimizing the material handling process at high temperatures.

● Plastic Pellet Level Measurement

In the plastic manufacturing industry, Fork-11 detects the level of plastic pellets in silos, ensuring consistent material levels even in hot environments.