Fork-11 Ultra-high Temperature Tuning Fork Level Switch

Fork-11 Ultra-high Temperature Tuning Fork Level Switch. It is featured with the function of water cooling (air cooling) and is able to work reliably under ultra-high temperature conditions that up to 400℃.

The Fork-11 Ultra-high Temperature Tuning Fork Level Switch is designed to withstand extreme conditions with its advanced water (or air) cooling function. It delivers unparalleled reliability in environments with ultra-high temperatures up to a staggering 400°C (752°F). This makes it the perfect solution for even the harshest industrial applications, ensuring precise and consistent material level detection in processes subjected to intense heat. Whether in high-temperature manufacturing or demanding industrial settings, Fork-11 stands as the go-to choice for maximum durability and performance.

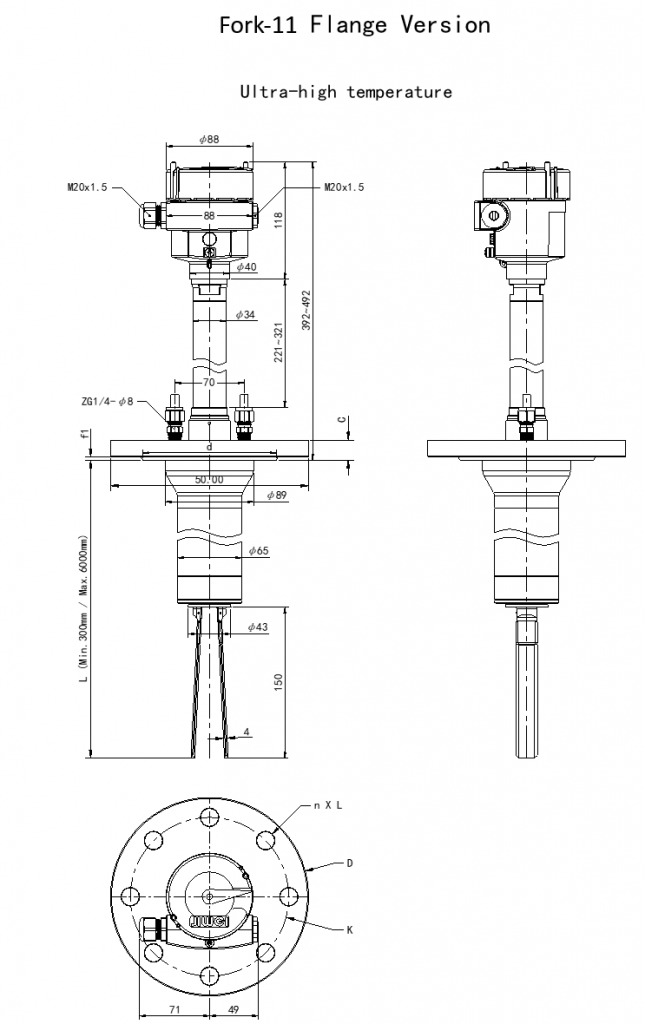

The Jiwei Fork-11 Ultra-high Temperature Tuning Fork Level Switch operates on the same principle as the standard Fork-11 series, with the key difference being the addition of an innovative cooling sleeve pipe. One end of this cooling sleeve pipe is welded to the process connection (flange), featuring air/water intake and vent. The other end is connected to the vibrating probe. Through a capillary copper tube, air or water flows into the vibrating probe, effectively drawing heat away and cooling the piezoelectric ceramics and wires to maintain the allowable working temperature. This cutting-edge design allows the Fork-11 Ultra-high Temperature Tuning Fork Level Switch to function reliably at temperatures up to 400°C (752°F), greatly expanding its applicability in high-temperature industrial processes.

● High-Temperature Resistant Design: With a process temperature tolerance of up to 400°C (752°F), ensuring reliable operation even in extreme conditions.

● Precise Tine Design and Resonance Adjustment: The tines are designed for optimal performance, with precise harmonic frequency adjustments. The Fork-11 can measure densities as low as 0.008g/cm³, making it ideal for ultra-light materials.

● Effective Powder and Bulk Solid Measurement: Particularly well-suited for powdery, fine-grained bulk solids, this design helps effectively prevent material buildup, ensuring consistent and accurate measurements.

● Advanced Self-Diagnostic Features: Equipped with a strong self-diagnostic function, the Fork-11 helps accurately pinpoint faults, reducing downtime and maintenance.

● Easy Installation and Maintenance-Free: Designed for straightforward installation and requiring no ongoing maintenance, reducing operational costs.

● Certified Safety and Compliance: The Fork-11 is CE certified, with Gas and Dust Flameproof Enclosure and Intrinsic Safety certifications, ensuring safety in hazardous environments.

● Durable and Corrosion-Resistant: Made with 316L stainless steel, this model offers excellent resistance to corrosion, ensuring a long lifespan in harsh environments.

| Applicable medium | Types of the Medium | powders or granular solids |

| Density | ≥0.008 g/cm³ | |

| Medium size | Max. 10mm | |

| Probe data | Vibration frequency | ~140Hz |

| Fork length | 150mm | |

| Switching Delay | When immersed | 0.5s |

| When laid bare | 1s | |

| Power supply① | Relay | 20~253V AC/20~72V DC |

| Two-wire | 10~36V DC | |

| Max. power consumption | 8VA(AC);1.5W(DC) | |

| Output | Relay | DPDT, 5A/253V AC/24V DC |

| Two-wire | 8mA/16mA, Alarm <2.3mA | |

| Installation conditions② | Process pressure | -1~25bar |

| Process temperature | Regular temperature: -50~150℃ High temperature: -50~250℃ Ultra-high temperature: -50~400℃ | |

| Ambient temperature | -40~80℃ | |

| Storage and transport temperature | -40~80℃ | |

| Cooling system data (for Ultra-high temperature only) | Air intake tube | 6×4 (Outer diameter 6mm) PU tube |

| Cooling air pressure | 8bar | |

| Min. cooling air flow rate | To be adjusted | |

| Overvoltage protection | Relay | Category III, class I |

| Two-wire | Category III, class II | |

| Certificates and approvals | Ingress Protection | IP66/IP67 |

| Explosion-Proof | Gas Intrinsic Safety: Ex ia IIC T1…T6 Ga | |

| Gas Flameproof Enclosure: Ex db IIC T1…T6 Gb | ||

| Dust Intrinsic Safety: Ex ia IIIC T₂₀₀100℃…T₂₀₀450℃ Da | ||

| Dust Protection Enclosure: Ex tb IIIC T80℃…T440°C Db | ||

| Gas/Dust Explosion-proof: Ex db IIC T1…T6 Gb + Ex tb IIIC T80℃…T440°C Db | ||

| CE | LVD and EMC Certificates | |

| Materials | Housing | Aluminum alloy, stainless steel |

| Ground terminal | 316L | |

| Process fitting | 316L, 316L coated PTFE | |

| Fork | 316L, 316L coated PTFE | |

| Process seal | Klingersil C-4400 |

Note:① The voltage of explosion-proof models can be executed according to the technical requirements on the Explosion-proof Certificate.

②The relationship between the process temperature, medium temperature and ambient temperature of explosion-proof models can be executed according to the technical requirements on the Explosion-proof Certificate.

● Power Plant Fluidized Beds:

The Fork-11 reliably measures fine particles such as ash and coal dust in fluidized bed systems, withstanding temperatures up to 400°C for continuous, accurate monitoring in power plant processes.

● Cement Production:

Used in cement plants, the Fork-11 accurately measures powdery materials in high-temperature silos (up to 400°C). Its design prevents material buildup, ensuring smooth operations in harsh environments.

● Fumed Silica Storage:

The Fork-11 is ideal for ultra-low density materials like fumed silica. With its high-temperature resistance (up to 400°C), it ensures precise level measurement in storage tanks without compromising reliability.

● Pharmaceutical Manufacturing:

In pharmaceutical industries, the Fork-11 operates reliably at temperatures up to 400°C. It measures powdery ingredients while complying with FDA, HACCP, and 3A standards, ensuring safety and hygiene.

● Chemical Processing:

In chemical reactors, the Fork-11 withstands extreme temperatures (up to 400°C) to measure fine-grained bulk solids, ensuring stable and precise process control in harsh conditions.

● Food Processing:

The Fork-11 handles high-temperature powders (up to 400°C) in food production, ensuring accurate level measurement while meeting food safety standards like FDA and HACCP.

● Waste Incineration:

In incineration facilities, the Fork-11 measures fly ash and other fine particles at temperatures up to 400°C, maintaining accurate monitoring for efficient and safe waste management.

● Steel Manufacturing:

The Fork-11 is used in steel mills to monitor materials like slag at temperatures up to 400°C. Its high-temperature tolerance ensures reliable level measurement in these tough environments.