Jiwei Radar Level Meter Empowers Lubricating Oil Company in Rotterdam for Precise and Reliable Level Measurement

Project Background Radar Level Meter

Lubricating oil is critical for the smooth operation of mechanical equipment, and accurate liquid level measurement directly impacts equipment safety and production efficiency. For lubricating oil storage tanks and pipeline systems, using high-precision level measurement instruments is essential. Rotterdam Lubricants BV, a leading lubricating oil producer located in the major European port city of Rotterdam, Netherlands, faced complex measurement environments and strict safety requirements. The company selected Jiwei Automations, a top-tier Chinese smart instrument manufacturer, to deploy their radar level meters and tuning fork level switches to ensure accurate and reliable level measurement.

This article explores the practical applications of lubricating oil level measurement, highlighting how Jiwei radar level meters meet complex operating conditions, common challenges, and their solutions—illustrated with a real project case at Rotterdam Lubricants BV.

Unique Challenges in Lubricating Oil Level Measurement

Lubricating oil level measurement presents specific challenges:

- Special medium characteristics: Lubricating oil has high viscosity and is sensitive to temperature changes, resulting in poor fluidity. Foam and vapor often form inside tanks, demanding high interference resistance from level instruments.

- Complex tank structures: Many lubricating oil tanks are equipped with agitators and heating systems, creating variable internal conditions. Conventional sensors are often disturbed by mechanical parts.

- High safety and environmental requirements: Lubricating oil is flammable and explosive, requiring instruments compliant with international explosion-proof standards such as ATEX and IECEx.

- Strict accuracy and stability demands: Measurement errors can disrupt stable oil supply, jeopardizing equipment protection and operational reliability.

Choosing the right high-performance level measurement instruments is critical under these demanding conditions.

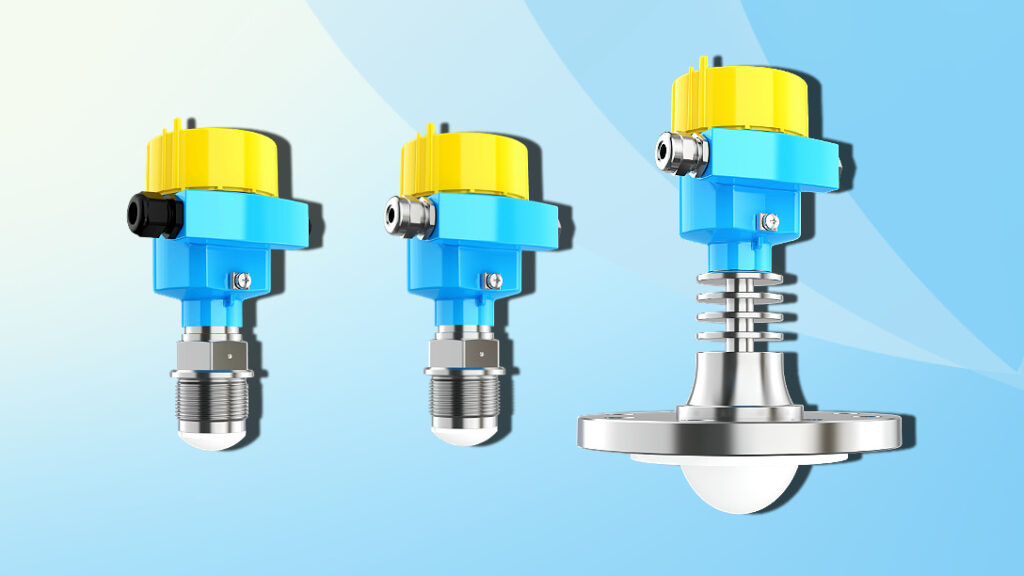

Advantages and Technical Features of Jiwei Radar Level Meter

Jiwei Automations’ radar level meter utilizes advanced 80GHz high-frequency wave technology, offering:

- Non-contact measurement: Radar waves travel through air without direct contact with lubricating oil, eliminating contamination, abrasion, and adhesion, significantly extending sensor life.

- Narrow beam and strong interference resistance: The 80GHz frequency generates an ultra-narrow beam that bypasses internal obstacles such as agitators and piping, minimizing measurement errors.

- Intelligent signal processing algorithms: Advanced filtering differentiates between true liquid surface reflections and vapor or foam interference, stabilizing output data.

- Wide temperature adaptability: Operating range from -40°C to +220°C covers the full temperature spectrum of lubricating oil storage conditions.

- Explosion-proof and corrosion-resistant design: Certified to international explosion-proof standards (Ex) and IP67 rated for harsh industrial environments.

Tuning Fork Level Switches Enhancing Safety Protection

In addition to radar level meters, Jiwei’s tuning fork level switches play a vital role in the project, offering:

- Simple structure and high sensitivity: Ideal for overflow alarms, pipeline blockage detection, and upper/lower level control in lubricating oil tanks.

- Customized anti-adhesion and explosion-proof design: Addressing viscosity and temperature-induced false alarms, improving operational stability and longevity.

Real-World Case: Rotterdam Lubricants BV

Challenge 1: Vapor interference causing unstable readings

During heating, large volumes of vapor formed inside lubricating oil tanks. Traditional radar meters suffered from signal distortion and fluctuating level readings.

Solution: Jiwei’s engineering team optimized sensor installation angles and adjusted emission power. Leveraging 80GHz narrow beams and intelligent algorithms, the system filtered vapor noise, improving reading stability by over 90%.

Challenge 2: False alarms due to high viscosity variation

Temperature fluctuations caused viscosity changes, leading to frequent tuning fork switch false alarms, affecting safety controls.

Solution: Jiwei’s patented temperature compensation technology dynamically adjusted sensitivity based on real-time conditions. Anti-oil-fouling coatings further ensured long-term reliable operation.

Challenge 3: Centralized monitoring of multiple tanks

With numerous distributed tanks, manual inspection was costly and inefficient.

Solution: Jiwei implemented an industrial protocol-based digital monitoring system integrating all radar meters and tuning forks. Real-time data upload to a centralized platform enabled remote monitoring and instant alarms, greatly improving operational efficiency.

Project Results and Industry Insights

Since deploying Jiwei Automations’ level measurement system, Rotterdam Lubricants BV has achieved:

- Level measurement accuracy within ±2mm

- Over 80% reduction in tank overflow incidents

- 30% cut in maintenance costs and significantly reduced downtime

- Enhanced safety and efficiency through real-time remote monitoring

This project clearly demonstrates the outstanding performance and practical value of Jiwei radar level meters and tuning fork level switches in demanding lubricating oil applications.

Conclusion

Lubricating oil level measurement faces challenges of complex media properties, variable environments, and high safety risks. Jiwei Automations’ 80GHz radar technology combined with smart tuning fork switches and digital management solutions successfully helped Rotterdam Lubricants BV overcome these obstacles, ensuring precise, stable, and safe liquid level monitoring.

Looking ahead, as industrial automation and IoT evolve, Jiwei Automation will continue advancing intelligent level measurement solutions, delivering safer and more efficient operations to lubricating oil and petrochemical industries worldwide.