Tube-11 Vibrating Rod Level Switch: Installation and Application Guide

The Tube-11 Vibrating Rod Level Switch is a modern level detection instrument widely used in industrial process control. Designed primarily for detecting the level of granular and powdered bulk solids, it supports materials with a minimum measurable density of 0.02g/cm³. With performance indicators that meet advanced industry standards, the Tube-11 offers exceptional reliability and operational stability.

Correct Model Selection Is Crucial

To ensure reliable performance of the Tube-11 vibrating rod level switch, it is essential to choose the correct model based on site conditions. Selection criteria should include:

- Bulk material density

- Operating temperature

- Process connection specifications

- Signal output type

- Probe insertion length

- Explosion-proof requirements

Before installation, verify that the selected model matches environmental and safety requirements of the application site.

Common Installation Methods for the Tube-11 Vibrating Rod Level Switch

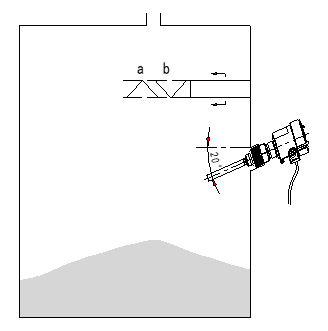

1. Horizontal Installation

To enhance measurement accuracy, the Tube-11 can be installed horizontally. For applications where slight measurement deviation (a few centimeters) is acceptable, it is recommended to tilt the probe downward by approximately 20°. This helps prevent buildup of material on the rod, reducing the risk of false alarms.

For fast-flowing or rapidly filling materials, protective baffles are recommended to shield the probe and ensure reliable operation.

a: Inverted V-shaped baffle

b: Upright V-shaped baffle

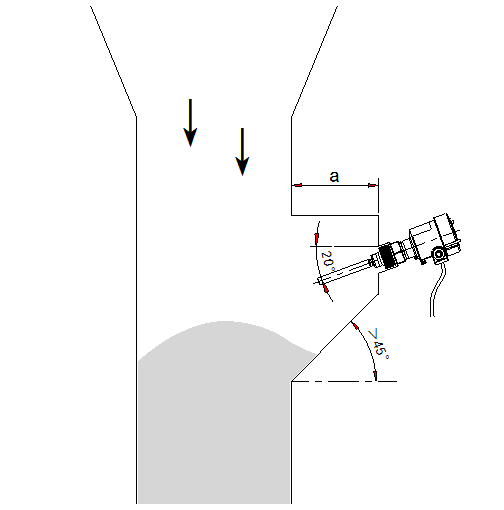

2. Recessed Installation (Wall Niche)

For materials with high density or large particle size, especially when falling vertically, it is advised to install the switch in a recessed wall niche. This prevents the probe from being damaged or bent due to material impact and prolongs the instrument’s service life.

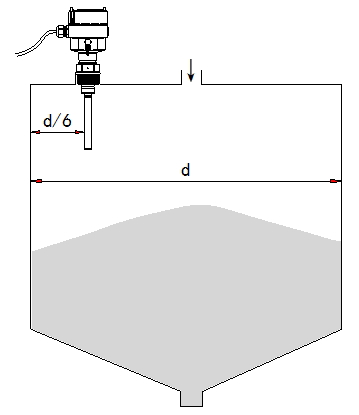

3. Vertical Installation

When installing vertically in cylindrical silos or hoppers, avoid placing the sensor directly in the center or near potential buildup zones. Instead, install the Tube-11 at approximately 1/6 of the tank diameter (d/6) from the wall to prevent errors caused by conical piles or sidewall accumulation.

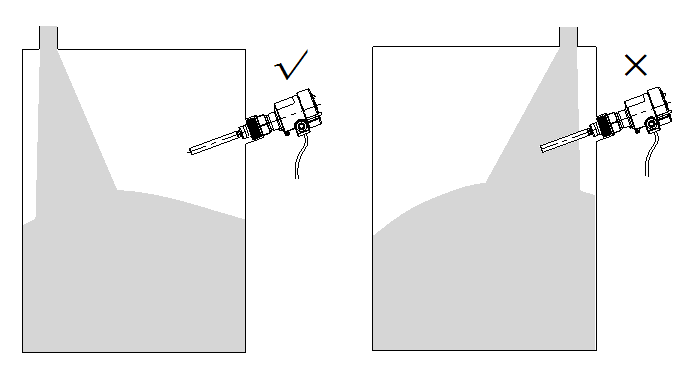

4. Avoid Inlet Area Installation

Avoid installing the Tube-11 directly below the material inlet to prevent:

- Measurement inaccuracies due to turbulent filling

- Physical damage from direct material impact

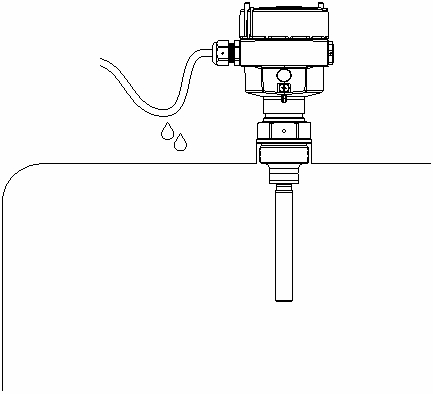

5. Moisture-Proof

For outdoor or high-humidity environments, moisture ingress must be avoided. To prevent rainwater or condensation from entering the housing through the cable gland:

- Route the cable downward in a drip loop before connection.

- Always ensure a tight seal at the cable entry point.

Electrical Connection and Configuration

Important: Always connect wiring with the power turned off. For explosion-proof models, follow all applicable wiring regulations and guidelines.

Sensitivity Adjustment

The Tube-11 is equipped with a sensitivity (density) adjustment switch on the control panel. It can be set to match the bulk density of the measured material.

- Factory default: Rightmost position, suitable for materials ≥0.05g/cm³

- Leftmost position: Enables detection of ultra-light materials with densities as low as 0.02g/cm³

This flexibility enhances adaptability across various applications and improves detection reliability.

High/Low Mode Configuration

For applications involving overflow protection or dry-run prevention, configure the High/Low alarm mode switch based on actual site requirements. This ensures the output signal aligns with the desired control logic.

Maintenance and Troubleshooting

To maintain optimal performance, routine maintenance by qualified technicians is recommended:

- Check the status LED indicators regularly for normal operation

- Inspect the probe for buildup and clean as needed to prevent false alarms

- Follow the troubleshooting guide in the user manual when faults are detected

- For unresolved issues, contact the manufacturer’s technical support team

By following proper selection, installation, and maintenance procedures, the Tube-11 vibrating rod level switch delivers reliable, stable, and long-lasting performance in a wide range of bulk solid level measurement applications. Whether used in silos, hoppers, or storage tanks, it effectively handles materials of varying densities, including ultra-light powders as low as 0.02g/cm³. Its robust design, high sensitivity, and minimal maintenance requirements make it ideal for use in cement, grain, chemical, and plastic processing industries, even in challenging environments with dust, vibration, or high humidity.