Fork-11 Tuning Fork Level Switch in Pre-expander Foam Control

The pre-expander machine is a critical piece of equipment in the production of foam plastic products, primarily used for the pre-expansion of materials such as expanded polystyrene (EPS) and expanded polypropylene (EPP). Accurate level control plays a vital role in the operation of the pre-expander, ensuring uniform density of the expanded particles and preventing quality issues such as particle agglomeration, excessive moisture, shrinkage, and unstable expansion ratios. Improper level control not only leads to batches of non-conforming material but can also cause machine shutdowns for cleaning, severely impacting production efficiency. Due to the low density of foamed particles inside pre-expanders, most domestic level measurement instruments struggle to meet requirements, and this field has long been dominated by imported products.

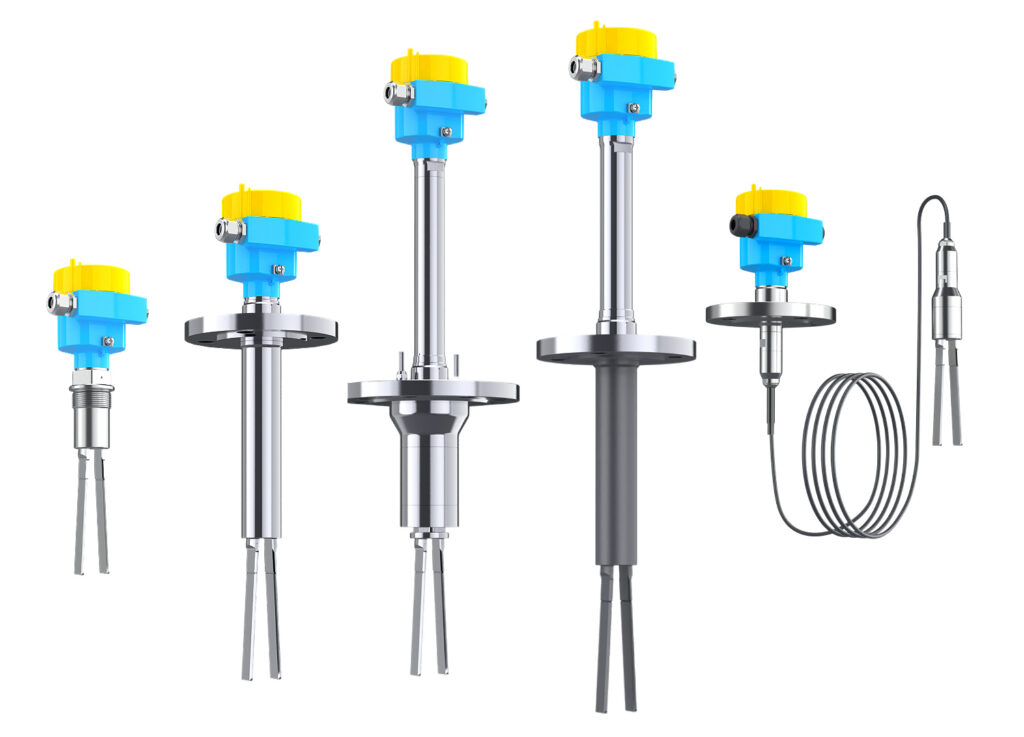

However, this situation is changing thanks to Jiwei Automations’ Fork-11 tuning fork level switch, which successfully replaces imported devices in pre-expander applications. So, why can Jiwei’s Fork-11 accurately measure levels in pre-expanders where most domestic instruments fail?

Challenges of Level Measurement in Pre-expanders and Advantages of Jiwei’s Fork-11 Tuning Fork Level Switch

The main difficulty for many level switches to accurately measure in pre-expanders stems from the unique characteristics of the foamed material. Manufacturers using pre-expanders are well aware that the density of the foamed material is very low, sometimes as low as 8 g/L. However, most domestic level switches are designed to detect higher-density media, and only a handful can reliably measure densities as low as 8 g/L. Additionally, the foamed particles exhibit some stickiness, making them prone to adhering to the tuning fork probes. If the two fork tines cannot fully resonate due to material adhesion, even a small amount of stuck particles can trigger false alarms, compromising measurement accuracy.

These two challenges—low material density and adhesion—have acted as major obstacles, preventing most domestic manufacturers from entering the pre-expander level measurement market, which has therefore remained dominated by imported products.

Thanks to the successful application of Jiwei’s Fork-11 tuning fork level switch in major domestic factories located in Guangzhou, Hangzhou, Dongguan, Jiangsu, and other regions, its product quality comparable to imports has gradually broken the monopoly of foreign brands in this field and gained unanimous praise from users. What advantages enable Jiwei’s Fork-11 to accurately measure low-density materials in pre-expanders and successfully replace imported products?

Jiwei Fork-11 Tuning Fork Level Switch for Low-Density Level Measurement in Pre-expanders

Firstly, the Fork-11 tuning fork level switch, independently developed and manufactured by Jiwei Automations, can measure media densities as low as 8 g/L, perfectly meeting the detection needs of low-density foamed materials in pre-expanders. Each unit undergoes rigorous fine-tuning and multiple performance tests before leaving the factory to ensure extremely high sensitivity and stability. This high sensitivity is the fundamental basis for accurate and reliable measurement, enabling effective detection of subtle changes in low-density materials while avoiding missed or false signals.

Secondly, the Fork-11 Tuning Fork Level Switch features a thin fork tine design with a relatively wide gap between the two tines. This innovative structural design effectively prevents bridging and material adhesion issues. Optimizing the fork structure not only reduces interference caused by sticking material but also significantly lowers the risk of false alarms triggered by adhesion. With these two core technological guarantees, Jiwei’s Fork-11 achieves stable and precise level measurement under complex conditions, making it the ideal choice for low-density foam material detection in pre-expander machines.

This comprehensive approach demonstrates why Jiwei Fork-11 Tuning Fork Level Switch is setting a new domestic benchmark, offering a reliable, cost-effective alternative to imported level measurement instruments in the demanding pre-expander industry.