High-Reliability Level Measurement Technology in Steel and Environmental Processes

Recently, senior engineers from the Jiwei Automations technical department conducted on-site visits to a major domestic steel mill and a power plant project to investigate the level measurement requirements under high-temperature, high-dust, and corrosive conditions. Through in-depth discussions with plant process, automation, and safety management teams, valuable first-hand feedback was collected, providing essential data for product optimization.

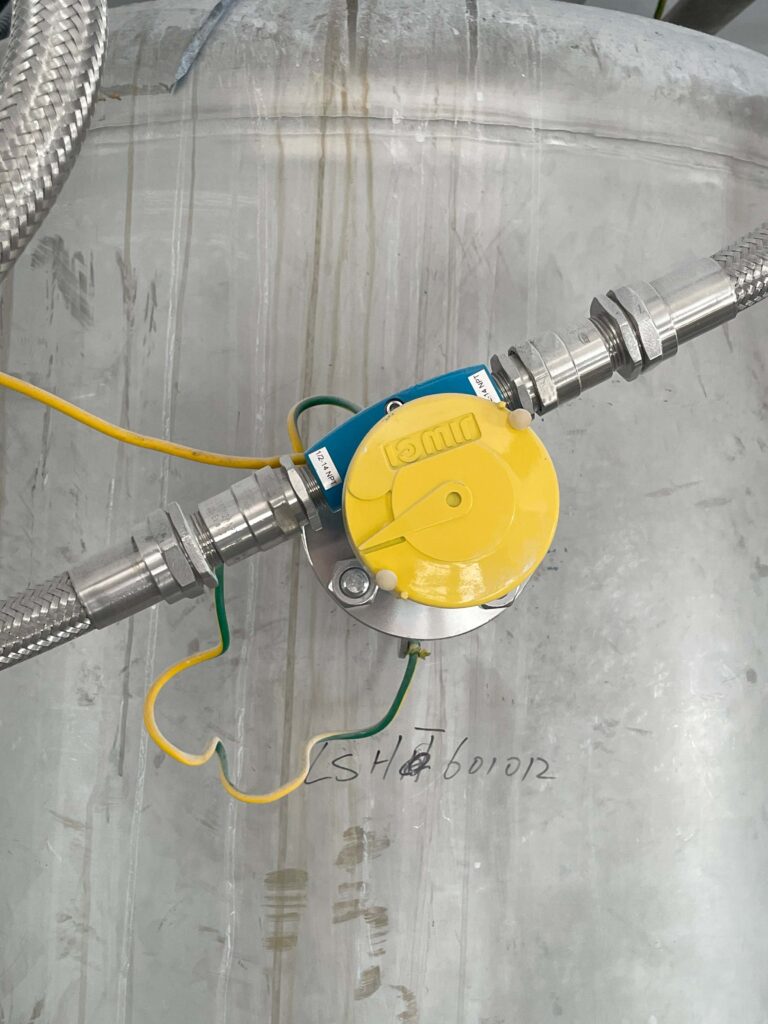

Notably, Jiwei’s Vibrating Rod Level Switches (Tube-11) and RF Admittance Level Switches (Cape-11) have been widely deployed in major steel enterprises including Ansteel, Liuzhou Steel, Baosteel, Wuhan Steel, and Shagang, as well as in critical applications such as flue gas desulfurization and denitrification, power plant emission control, and chemical slurry storage tanks.

Jiwei Vibrating Rod Level Switches (Tube-11)

1. Applications in Steel Production

Blast Furnace Hopper Level Control

Iron ore powder, coke, and pellet materials stored in blast furnace hoppers require highly reliable level monitoring. Traditional mechanical float or optical switches often fail in high-dust, high-temperature, and vibration-prone environments. Jiwei Tube-11 Vibrating Rod Level Switches utilize solid-state vibration detection technology. The sensor rods are wear- and heat-resistant, providing reliable point-level detection and stable alarm signals under harsh conditions, ensuring precise level monitoring in blast furnace hoppers.

Waste and Slag Storage Hoppers

Blast furnace waste, slag, and other powder materials present high corrosivity, wear, and elevated temperature conditions, posing stringent requirements for level measurement devices. The Tube-11 employs a 316L stainless steel dual-rod sealed structure, with sensors tested for high-temperature and abrasive environments. It delivers long-term stable point-level alarms under corrosive, dusty, and high-temperature conditions (up to 400°C), ensuring safe storage and continuous production processes.

Jiwei RF Admittance Level Switches (Cape-11)

2. Applications in Steel and Complex Material Handling

Steelmaking Dust and Granular Material Monitoring

During steelmaking and raw material handling, high dust concentrations and uneven particle distribution can cause false alarms or failures in conventional level switches. Jiwei RF Admittance Level Switches detect level changes via the admittance variation when probes contact material, with no moving parts, enabling stable, long-term operation under high dust, high temperature, and corrosive environments. Suitable for powders, granules, and slurries, these switches are widely used in hoppers, silos, and conveyors, providing reliable point-level monitoring.

Corrosive or High-Temperature Powder Applications

In steelmaking processes such as pickling, chemical treatment, and flue gas desulfurization/denitrification, powders or slurries often exhibit corrosivity and high temperatures. Cape-11 switches feature high-corrosion-resistant sealing materials and are rated for up to 450°C, allowing stable level measurement in steam, dust, and corrosive media, ensuring process safety and continuous production.

Low-Dielectric Powder Measurement

Certain powders or slurries in steel and environmental processes have low dielectric constants, which are challenging for standard capacitive switches. Cape-11 switches optimize probe design and admittance signal processing, allowing accurate detection of low-dielectric powders and granules, widely applied in fly ash, gypsum, and lime slurry storage tanks.

3. Applications in Desulfurization, Denitrification, and Environmental Processes

Desulfurization Tower Level Control

In flue gas desulfurization, monitoring the levels of lime and gypsum slurry is critical. Low levels may cause pump dry-running, while high levels may result in overflow. Jiwei Vibrating Rod and RF Admittance Level Switches provide stable point-level detection in high-dust, high-steam, and corrosive environments, ensuring continuous operation and process safety.

Denitrification Reactor Level Monitoring

Slurries or powders used in selective catalytic reduction (SCR) reactors often present high temperatures, steam, and corrosivity. Cape-11 switches, with high-temperature and corrosion-resistant designs, maintain reliable level measurement in reaction tanks, hoppers, and storage silos.

High-Solids Waste Storage

In power plants, chemical plants, and steel mills, storage silos and mixing tanks for acidic, alkaline, or high-solids waste pose challenges for level control. Jiwei Tube-11 and Cape-11 switches, with corrosion-resistant designs and robust structures, reliably provide point-level alarms in high-dust, high-temperature conditions, ensuring safe operation of silos, pump feeds, and mixers.

4. Technical Advantages and Customer Value

Jiwei Tube-11: Industry-Leading Dual-Rod Technology

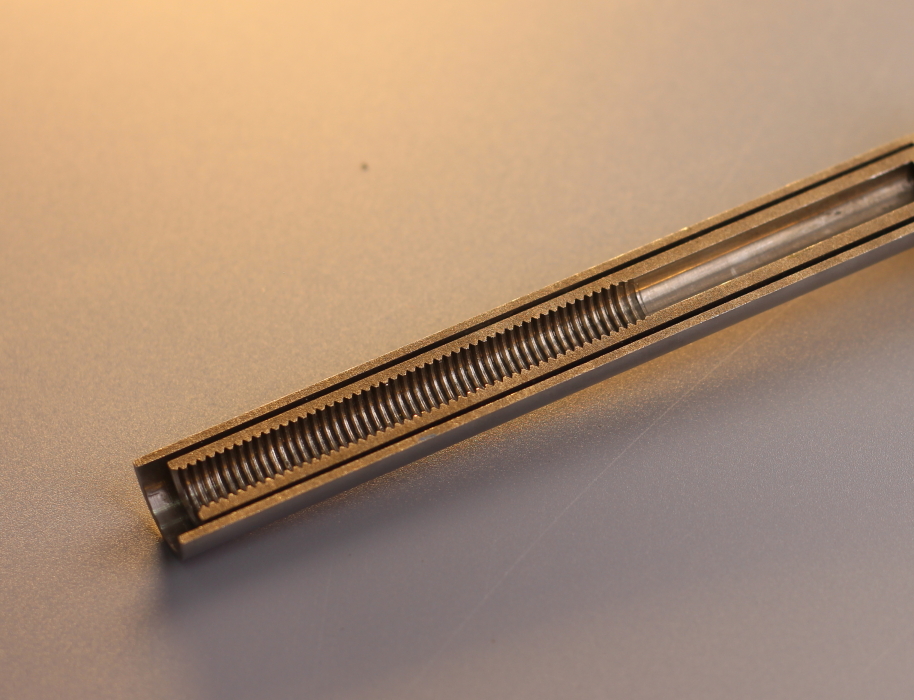

The dual-rod probe design of Tube-11 is precision-tuned for high sensitivity (dual-rod cross-section illustrated). The Tube-11 can detect low-density materials down to 0.02 g/cm³ while maintaining stable operation under high-temperature, high-dust, and corrosive conditions. Key advantages include:

- High-Temperature Resistance: Up to 400°C, significantly exceeding VEGA’s 250°C, suitable for high-temperature steel and chemical silos.

- Low-Density Detection: Measures materials as light as 0.02 g/cm³, outperforming VEGA’s single-rod design.

- Safety and Explosion Protection: Certifications covering gas, dust, and high-temperature environments (Ex db IIC T1–T6 Gb; Ex tb IIIC T80℃–T440℃ Db; Ex ia II C T1–T6 Ga; Ex ia IIIC T200 100℃–T200 450℃ Da).

- Low Maintenance: Solid-state design with virtually maintenance-free operation.

- Cost Efficiency: Approximately 2/3 the price of VEGA products, offering excellent cost-performance.

Real-World Cases:

- Steel Mill Silos: VEGA single-rod switches in pellet silos experienced false alarms with low-density iron powder. Replacing with Tube-11 achieved stable, reliable point-level detection.

- Environmental Desulfurization Systems: High dust and steam conditions in desulfurization towers were effectively monitored with Tube-11, replacing imported brands for accurate level control.

Customer Value:

- Enhanced Production Efficiency: Accurate level measurement ensures continuous operation, reducing downtime and misoperations.

- Lower Maintenance Costs: Solid-state, long-life design minimizes maintenance frequency.

- Improved Safety: Explosion-proof, corrosion-resistant, and high-temperature capable.

- Imported Equipment Replacement: Jiwei products fully replace VEGA and other imported brands, delivering superior performance at lower cost.

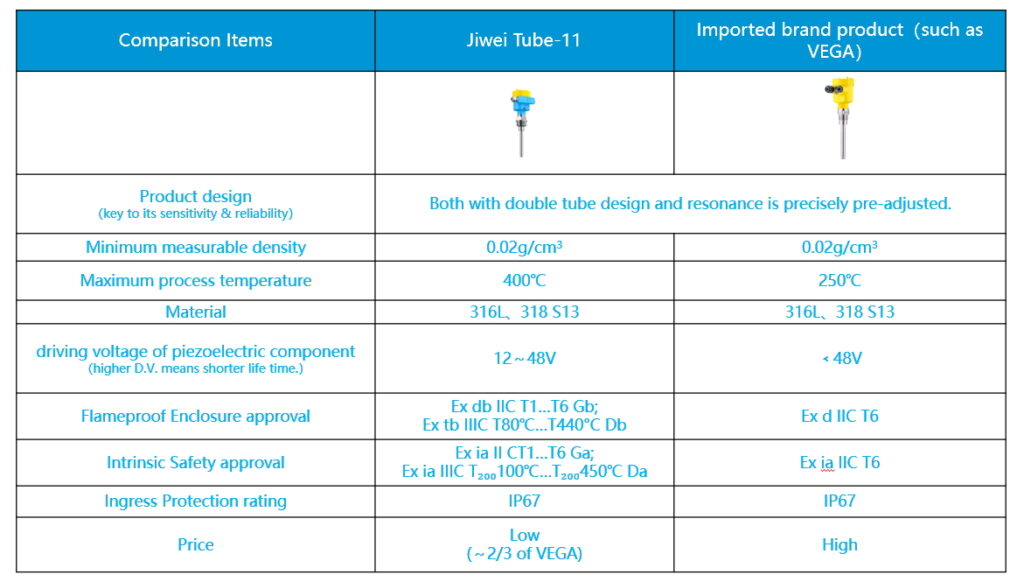

5. Key Performance Comparison

| Comparison Item | Jiwei Tube-11 | Imported Brand (VEGA) |

|---|---|---|

| Maximum Process Temperature | 400℃ | 250℃ |

| Minimum Measurable Density | 0.02 g/cm³ | 0.02 g/cm³ |

| Measurable Media | Solid powders, granules | Solid powders, granules |

| Flameproof Certification | Ex db IIC T1–T6 Gb; Ex tb IIIC T80℃–T440℃ Db | Ex d IIC T6 |

| Intrinsic Safety Certification | Ex ia II C T1–T6 Ga; Ex ia IIIC T200 100℃–T200 450℃ Da | Ex ia IIC T6 |

| Maintenance Cost | Low, virtually maintenance-free | Medium |

| Price | ~2/3 VEGA | High |

6. Conclusion

Jiwei Tube-11 Vibrating Rod Level Switches and Cape-11 RF Admittance Level Switches, with high-temperature tolerance, low-density detection, corrosion resistance, explosion-proof certification, and low maintenance requirements, have been widely adopted in major steel companies including Ansteel, Liuzhou Steel, and Baosteel. They excel in steel silos, environmental desulfurization/denitrification systems, and power plant boiler silos, providing customers with safe, stable, and efficient level management. Jiwei has set a benchmark for high-end domestic level measurement equipment.