Buffer Silo Level Measurement Solutions in Ethanol Plants

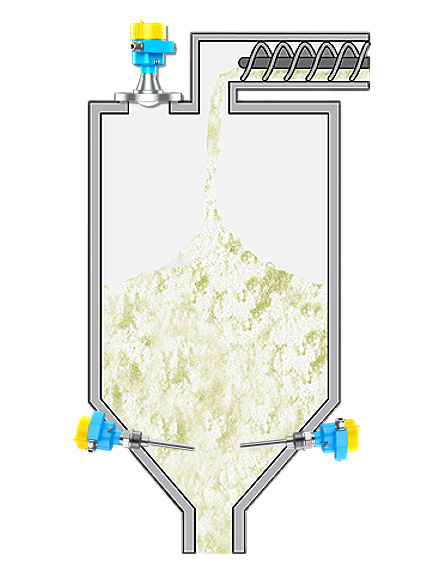

In the renewable energy sector, biomass ethanol has become a key component of green fuel strategies, gradually replacing traditional fossil fuels. In ethanol production, the stable supply of raw materials directly impacts production efficiency and economic performance. To ensure continuous downstream fermentation and distillation processes, crushed grain is temporarily stored in buffer silos to handle production peaks and fluctuations in raw material delivery.

However, buffer silos in ethanol plants present extremely challenging operating conditions. Material is transported directly from mills to silos at high speed, creating significant mechanical stress on silo structures and measurement equipment. Dust generated during storage and transfer can interfere with measurement instruments, leading to inaccurate readings. Without high-reliability level measurement systems, silos risk overfilling or running empty, potentially causing production downtime or safety incidents.

Achieving high-precision, stable, and reliable continuous level measurement and point level detection is therefore critical for efficient buffer silo management in ethanol plants.

Challenges in Buffer Silo Level Measurement

Level measurement in ethanol plant buffer silos faces multiple operational challenges:

- High Dust Concentrations: Fine powdered grain produces dense dust clouds during storage and transfer, disrupting measurement signals and increasing maintenance demands.

- Mechanical Impacts: Continuous material drop impacts place extreme stress on instruments, potentially causing damage or inaccurate readings.

- Continuous Operation: Ethanol production lines operate 24/7, requiring instruments to maintain stable operation without false alarms or downtime.

- Limited Installation Space: Internal structures like beams, stiffeners, and auxiliary equipment restrict radar beam alignment and installation flexibility.

Traditional mechanical level switches and ultrasonic sensors often fail to deliver reliable measurements under these conditions, with signals easily affected by dust, airflow, and mechanical impacts.

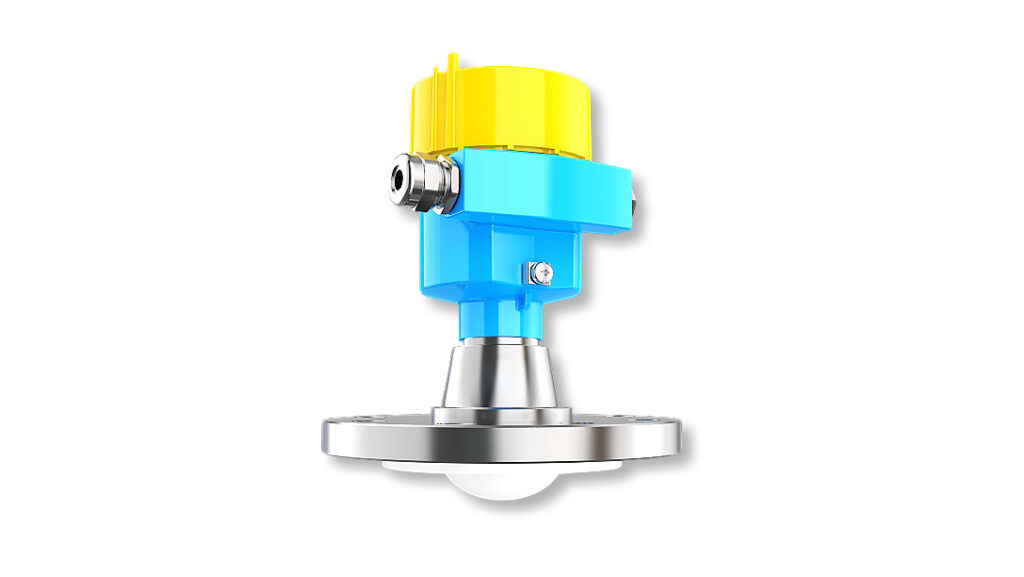

Jiwei JWrada® Radar Level Meter: Reliable Continuous Measurement

Jiwei Automations’ JWrada® radar level meter is engineered for high-precision, continuous measurement in complex environments. Using 80 GHz FMCW radar technology, it features a narrow, dust-penetrating beam that accurately detects material levels even in high dust and high-impact conditions.

Key advantages of JWrada® include:

- Sub-Millimeter Accuracy: Detects minor level variations, ensuring continuous downstream feeding and preventing over- or under-supply.

- Intelligent Echo Processing: Advanced algorithms differentiate real material surface signals from dust or air disturbances, enhancing measurement reliability.

- Non-Contact Design: Prevents wear and buildup, reducing maintenance and supporting 24/7 operation.

- Easy Integration: Supports HART and Modbus protocols for direct DCS system integration.

- Bluetooth Calibration: The “Jiwei Smart Control” app allows rapid on-site calibration and setup, improving installation efficiency.

With JWrada®, ethanol plants achieve stable, high-precision continuous measurement, providing reliable data for production scheduling and process optimization.

Tube-11 Vibrating Rod Level Switch: Point Level Safety

For additional safety, silos require precise upper and lower limit detection. The Tube-11 vibrating rod level switch features a robust dual-probe design suitable for powders and granular materials.

Tube-11 advantages:

- Accurate upper and lower limit detection to prevent overfilling or empty silos.

- Smooth probe surface minimizes material adhesion, ensuring stable operation even with high moisture content.

- Explosion-proof certification ensures safe operation in dust-laden ethanol production environments.

When combined with JWrada® radar meters, the Tube-11 provides dual-layer protection, combining continuous measurement with point-level detection.

Practical Application

At a leading ethanol plant in Henan Province, JWrada® radar level meters and Tube-11 vibrating rod switches were deployed in buffer silos. The results were remarkable:

- Continuous, accurate level readings even under high-speed material fall and dense dust conditions.

- Reliable upper and lower limit detection prevented overfill and shortage, maintaining production continuity.

- Reduced maintenance and fewer manual inspections lowered operational risks.

- Real-time level data uploaded via Modbus to the DCS system enabled automated material scheduling.

Plant operators reported that buffer silo management became more scientific, safe, and efficient after implementing Jiwei’s solution.

Benefits of Jiwei Level Measurement Systems

Implementing Jiwei level measurement systems provides multiple benefits:

- Enhanced Reliability: Continuous measurement and point-level detection ensure stable production.

- Improved Economic Performance: Minimizes downtime and material waste, optimizing production costs.

- Operational Convenience: Bluetooth setup and remote monitoring simplify maintenance and increase operational efficiency.

- Safety Assurance: Dust explosion certification ensures safe operation in high-risk environments.

Conclusion

Buffer silos are vital in ethanol production, and accurate, reliable level measurement is critical. Jiwei JWrada® radar level meters and Tube-11 vibrating rod level switches overcome the limitations of traditional sensors in dusty, high-impact environments. Together, they provide continuous measurement and precise point-level detection, ensuring safe and efficient operation.

This domestically developed solution achieves performance comparable to, or exceeding, imported brands, with fast delivery and international export support. Jiwei’s instruments offer intelligent, safe, and cost-effective level measurement for ethanol plants and other powder handling industries. By combining precision, durability, and smart monitoring, Jiwei demonstrates that Chinese industrial instrumentation can meet international standards of reliability and performance.

SEO Keywords: ethanol plant, buffer silo, level measurement, radar level meter, vibrating rod level switch, JWrada®, Tube-11, continuous measurement, point level detection, dust-resistant, industrial automation, renewable energy