Dust + Steam + Corrosion? Challenge and Solution of 80GHz Radar Level Measurement

In modern industrial production, radar level measurement plays a pivotal role not only in process control but also in ensuring equipment safety and operational efficiency. However, when faced with the simultaneous presence of high dust concentration, saturated steam, and corrosive media, many traditional level measurement devices suffer from signal attenuation, false echoes, and even complete failure. This triple challenge is particularly common in chemical, metallurgical, energy, and LNG/LPG storage industries, making it one of the toughest problems in the field of level measurement today.

The Triple Challenge in Radar Level Measurement: Dust, Steam, and Corrosion

Dust contamination is a significant issue in environments such as cement plants, coal chemical facilities, and ore storage silos. High-speed loading and material friction create suspended particles that cause strong scattering and absorption of electromagnetic waves. For radars operating at lower frequencies with wider beam angles, such as 26GHz devices, dust reduces signal-to-noise ratio and can cause wall reflections to be mistaken for actual material echoes. This results in unstable or inaccurate level readings.

Saturated steam is another complicating factor, often found in heated storage tanks, reactors, and LNG vaporizer systems. The dielectric constant of saturated steam closely resembles that of liquids, which can cause radar signals to refract, attenuate, or generate multipath echoes. These effects often confuse measurement instruments and degrade reliability.

Furthermore, corrosive media such as acids, alkalis, salt fog, and chloride gases chemically attack radar antennas, seals, and housing materials, reducing the lifespan and long-term stability of the instruments.

80GHz Radar Level Measurement: A Technical Breakthrough

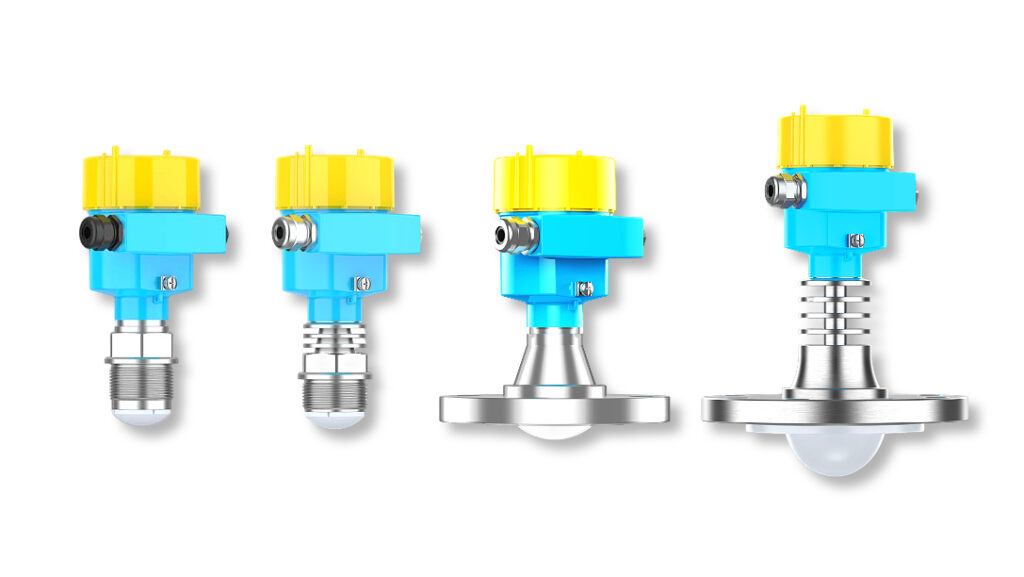

To overcome these challenges, Shenzhen Jiwei Automations developed the JWrada® 80GHz radar level measurement solution that integrates multiple technological innovations.

The 80GHz high-frequency radar signal features a narrow beam angle and concentrated energy, allowing it to penetrate dust layers effectively and minimize wall echoes. This narrow beam significantly enhances signal quality even under heavy dust conditions with uneven particle sizes.

Its intelligent echo recognition algorithm dynamically analyzes return signals, filtering out false echoes caused by dust and steam in real time. This ensures stable liquid level data even as the dielectric properties of the medium change or the temperature fluctuates.

In terms of corrosion resistance, JWrada® employs a fully encapsulated PTFE antenna combined with an aerospace-grade aluminum housing rated at IP68 for ingress protection. This construction withstands harsh environments involving strong acids, alkalis, and high salt concentrations, while maintaining long-term sealing reliability under high humidity and temperature.

Field Case: Coastal Chemical LNG Storage and Radar Level Measurement Success

A coastal chemical plant’s LNG storage system previously used imported 26GHz radar devices that frequently failed during hot and humid summer conditions due to signal loss and false level readings, severely disrupting loading schedules.

After deploying JWrada® 80GHz radar level measurement instruments, the Jiwei engineering team optimized beam orientation, activated steam interference compensation algorithms, and installed protective covers to slow salt corrosion. As a result, the system achieved over 12 months of zero downtime with a 98% increase in measurement stability and nearly 50% reduction in maintenance costs.

Software & Performance Advantages in Radar Level Measurement

JWrada® radar level measurement devices excel not only in hardware but also through advanced software capabilities:

- ±1mm Measurement Accuracy: Delivers ultra-precise level readings even in challenging environments with low dielectric constants and strong interference.

- Intelligent Echo Recognition: Filters out false echoes from dust, steam, and agitation, ensuring data purity and reliability.

- Multi-Scenario Adaptability: Automatically adjusts emission power and signal processing parameters for tanks, silos, reactors, and LNG storage vessels.

- Rapid Response Time: Capable of refreshing measurements every 0.1 seconds, suitable for processes with fast-changing liquid levels.

- Remote Configuration and Diagnostics: Supports HART, Modbus, and 4-20mA protocols, enabling remote tuning and health monitoring to minimize maintenance efforts.

- Big Data Integration: Seamlessly connects with DCS, MES, and cloud platforms to facilitate real-time monitoring, trend analysis, predictive maintenance, and optimized production scheduling.

These combined hardware and software innovations ensure that JWrada® radar level measurement instruments perform consistently in both laboratory tests and demanding field conditions, achieving high accuracy, reliability, and low total cost of ownership.

Conclusion: High-End Radar Level Measurement for Safety and Efficiency

As industrial operations increasingly require enhanced safety, operational continuity, and intelligent monitoring, the advantages of 80GHz radar level measurement technology become indispensable. From dust-heavy silos and steam-laden reactors to corrosive chemical tanks, JWrada® has proven itself as not just a measurement instrument, but a key enabler of safer and more efficient industrial processes.