Reliable Level Detection in Wood Pellet Dryers

Application Background

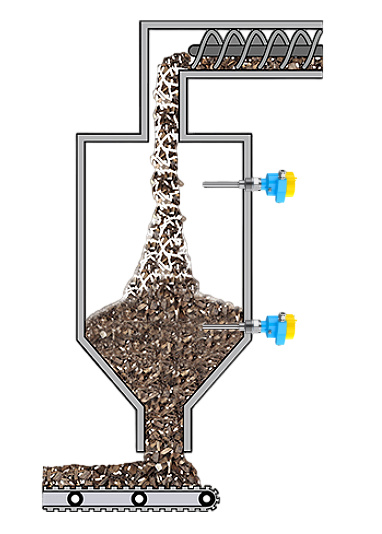

In the production of high-quality wood pellets, consistent raw material handling is the foundation for stable operation. Wood pellet plants rely on automated, continuous processes where raw wood is chipped, dried, and pressed under high pressure into dense pellets used as renewable fuel. One critical step occurs in the buffer tank in front of the drying facility. Here, fine wood chips are stored temporarily before entering the belt dryer.

At this stage, point level detection becomes essential. If material overfills the buffer tank, it can disrupt feeding to the dryer, cause mechanical stress, and lead to costly downtime. On the other hand, insufficient filling interrupts the drying process, reducing production efficiency.

The process conditions present several challenges:

- Medium: fine wood chips with variable density.

- Temperature: +20 … +60 °C, sometimes higher near the drying chamber.

- Pressure: 0 … 0 bar.

- Special challenges: material build-up and mechanical load on the sensor probe.

For reliable and automated operation, a robust point level switch is required—one that can withstand dust, material adhesion, and frequent filling cycles without false alarms.

Solution: Jiwei Vibrating Rod Level Switches

Traditionally, many European pellet plants adopted capacitive switches such as the VEGACAP series for level detection. However, Jiwei Automations offers a superior alternative with its advanced Tube-11 Vibrating Rod Level Switch, providing unmatched performance in wood chip handling.

Jiwei’s vibrating rod technology ensures precise switching, even in the presence of build-up, while guaranteeing stable operation under heavy mechanical loading. The rugged double-rod probe design sets a new benchmark for reliability and longevity in the bulk solids industry.

Compared to capacitive or single-rod devices, Jiwei’s double vibrating rods deliver a more reliable resonance principle that is less sensitive to changes in material properties such as moisture or density. This is especially valuable in wood chip applications, where particle size and moisture levels can vary significantly.

Why Jiwei is the Perfect Alternative to VEGA

Jiwei vibrating rod level switches are recognized as the perfect made-in-China alternative to VEGA—not only equivalent in performance but leading in innovation and durability. With advanced engineering and international certifications, Jiwei devices have become the preferred choice for many biomass energy facilities seeking dependable yet cost-effective solutions.

Key features making Jiwei the industry leader include:

● First made-in-China Vibrating Rod Level Switch with Double Rod Innovation

Jiwei pioneered the first Chinese vibrating rod level switch with innovative double vibration rods, creating industry-wide benchmarks. This design provides greater structural stability, enhanced sensitivity, and resistance to bending or abrasion.

● High Sensitivity for Fine Solids

By carefully adjusting resonant vibration frequencies, Jiwei switches achieve extraordinary sensitivity. They can detect fine-grained bulk solids with densities as low as 0.02 g/cm³, making them suitable for fine wood chips, sawdust, and lightweight biomass materials.

● Outstanding Temperature Tolerance

Wood pellet drying facilities often experience high ambient and process temperatures. Jiwei vibrating rods are designed to withstand up to 250 °C, and with water or air cooling options, they can operate reliably at ultra-high temperatures of 400 °C. This sets them apart from many competing products in the industry.

● Versatility in Applications

Beyond wood pellets, Jiwei vibrating rod switches excel in measuring sediments and precipitate interfaces. With suspension-type designs, they are ideal for tall and narrow silos, environments with vibrations, and even liquid-solid interface detection.

● Superior Anti-Buildup Performance

The double-rod construction allows for larger redundancy in oscillation, reducing the risk of false switching due to material adhesion. For adhesive or viscous biomass materials, Jiwei offers superior anti-buildup capability, ensuring uninterrupted operation.

● Enhanced Self-Diagnostics

Built-in diagnostic functions allow precise fault detection, reducing downtime. The rods are abrasion-resistant and long-lasting, even under heavy mechanical stress.

● Maintenance-Free and Product-Independent

Jiwei switches require no calibration and remain unaffected by changing product characteristics such as moisture content or density variations. Once installed, they provide maintenance-free, worry-free operation.

● Safety and Certification

Jiwei vibrating rod switches are fully certified with:

- CE

- Gas/Dust Flameproof Enclosure

- Gas/Dust Intrinsic Safety

- IP66/IP67 ingress protection

These certifications guarantee safe operation in dust-laden environments such as wood pellet plants.

● Anti-Corrosion Probes for Harsh Environments

Probes are available in 316L and 318 S13 stainless steel, providing robust corrosion resistance against acidic vapors and challenging biomass processing conditions.

● Hygiene and Industry Compliance

For broader industries beyond biomass, Jiwei vibrating rods comply with HACCP and 3A hygiene standards, ensuring safe and reliable use in the food and pharmaceutical sectors.

Benefits in Wood Pellet Production

By deploying Jiwei vibrating rod level switches at the charging point of the belt dryer, operators achieve:

- Reliable automation: Continuous and accurate filling control avoids overfill and underfill situations.

- Cost efficiency: Optimum dryer feeding ensures consistent drying, reducing energy costs and maximizing throughput.

- User-friendly operation: No recalibration needed, unaffected by buildup, ensuring smooth and hands-free operation.

- Industry-leading durability: Withstanding high temperatures and heavy dust load, Jiwei ensures maintenance-free reliability in challenging pellet environments.

Case Outcome

A European-style wood pellet production facility integrated Jiwei vibrating rod level switches into its buffer tanks. The results were immediate: no false alarms despite fine dust, smooth feeding to the dryer, and significantly reduced maintenance compared to older capacitive switches.

By adopting Jiwei’s solution, the plant improved efficiency, reduced downtime, and enhanced safety. Moreover, the long-term durability of Jiwei vibrating rods lowered operating costs, proving them to be a perfect long-term alternative to traditional imported brands such as VEGA.

Conclusion

The wood pellet industry demands rugged and reliable instrumentation for point level detection. With continuous innovation, robust construction, and internationally recognized certifications, Jiwei vibrating rod level switches stand out as the leading solution for biomass processing facilities worldwide.

Their ability to withstand high temperatures, detect fine solids, and operate maintenance-free under heavy dust conditions ensures that pellet plants achieve consistent quality, efficient drying, and safe automated production.

For plants seeking an industry-leading, cost-effective, and reliable alternative to VEGA, Jiwei provides the perfect choice—designed and manufactured in China, yet setting global standards in performance and durability.