From Sand Level Challenges to Level Switch Upgrade:Jiwei Engineers Visit Casting Equipment Manufacturers

Recently, the engineering team from Shenzhen Jiwei Automations Ltd. visited several automotive parts casting equipment manufacturers in Suzhou to conduct on-site technical exchanges and confirm improvement plans regarding challenges in sand conveying and sand-making processes. This visit allowed both parties to have in-depth discussions on key technical points, including sand core casting processes for complex internal engine pipes, reliability issues of precision sand level measurement, and the performance of rotary paddle and vibrating rod level switches in high-dust environments.

01 Complex Automotive Pipe Casting Requirements: High Precision, High Consistency, Single-Use Sand Cores

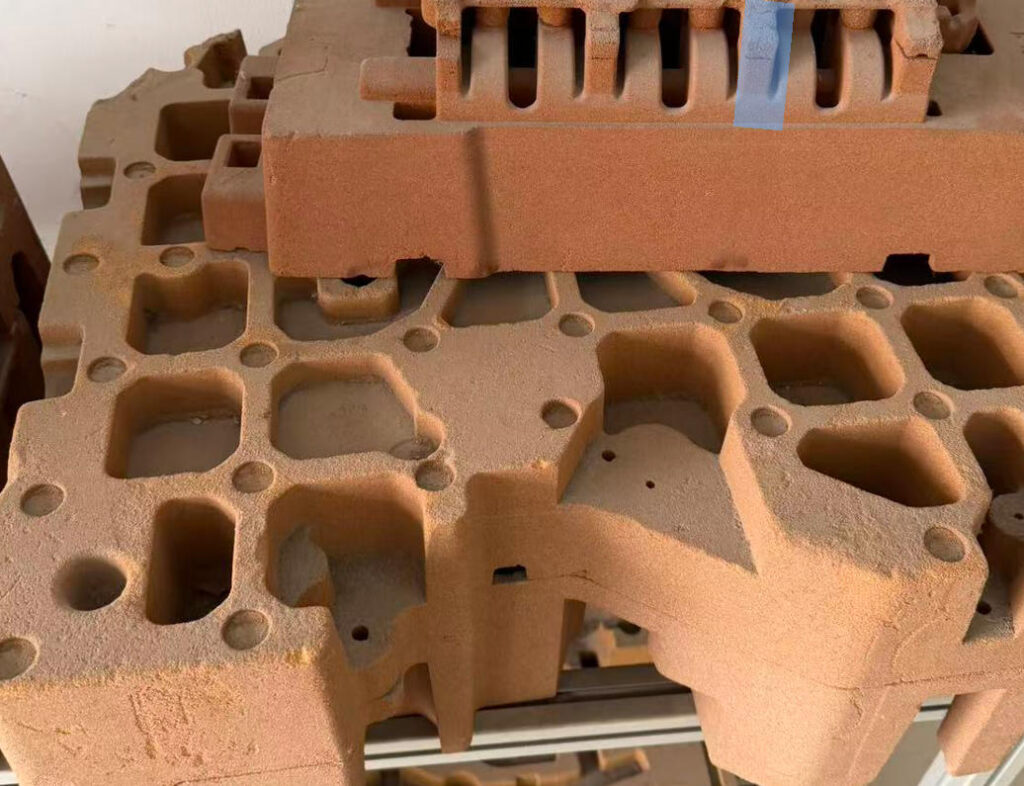

The Suzhou equipment manufacturers mainly serve automotive engine parts makers, particularly specializing in producing highly complex and irregular internal engine pipes. Internal components such as oil circuits, cooling channels, and vacuum lines rely on internal sand cores to form cavities. These pipes are often curved, irregular in cross-section, and finely detailed, placing extremely high demands on the control of sand core shapes.

Currently, the industry generally uses precision sand casting + die casting to produce these single-use sand cores. The process can be summarized as follows:

- Equipment manufacturers use precision sand casting to produce sand core molds, which are usually single-use hollow structures for forming internal channels of automotive pipes;

- Automotive manufacturers place the sand cores into external metal molds to pour molten metal or perform die casting, forming finished pipes with complex internal structures;

- After the pipes are formed, the internal sand cores are completely broken and discarded during shell-breaking or vibrating sand removal.

This means that every step in the sand core manufacturing process must be strictly controlled. In particular, the sand’s moisture, flowability, and mixing uniformity directly affect the quality of the final automotive components.

02 Sand Preparation Machines: Core Equipment but Long-Faced with “Unreliable Level Measurement” Industry Issue

On the sand core production line, sand preparation machines, sand mixers, and core shooters are the most critical equipment. Inside the sand preparation machines, high-pressure air is usually used to stir the sand to ensure uniform mixing and consistent particle size distribution. However, this high-pressure blowing also brings a long-standing industry problem:

Industry Pain Point: Rotary Paddle Level Switches Easily Jam

Many low-cost rotary paddle level switches easily experience the following failures under high-dust, high-permeability precision sand conditions:

- Insufficient shaft sealing allows dust to be continuously blown into the shaft seal structure;

- Fine sand penetrates the bearings and rotating chamber, causing internal moving components to stall;

- Dust accumulation in the protective chamber reduces the torque of the blades;

- Under heavy-duty conditions, rotation may be obstructed, resulting in jamming, false alarms, or long periods of inaction.

Especially in continuously operating, three-shift sand preparation machines, rotary paddle jamming can easily lead to abnormal sand ratios and unstable sand core strength, ultimately affecting the quality of the entire casting batch.

The Suzhou customer explicitly stated: “Many low-cost rotary level switches from other suppliers jam quickly due to poor sealing, and maintenance frequency is particularly high.”

03 Jiwei Rotary Paddle Switch: Years of Stable Operation, No Jamming, Recognized by Customers

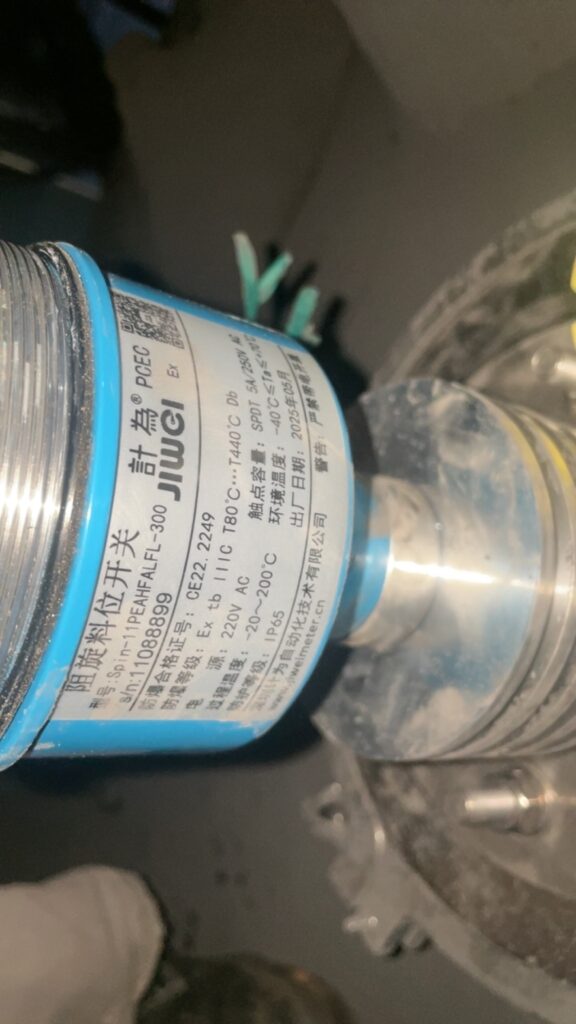

This equipment manufacturer has been using Jiwei Spin-11 rotary paddle level switches for several years. After long-term use, they highly affirmed the product’s stability. Jiwei rotary paddles can operate reliably for years in precision sand conditions without jamming, mainly due to:

- High-grade shaft seal design effectively preventing sand penetration;

- High-torque moving components maintaining rotation under certain sand pressure;

- Enhanced internal protective chambers preventing dust from entering the motion chain;

- High-quality industrial-grade bearings and motor components ensuring long-term wear-free operation.

The customer remarked: “Spin-11 level switch has never jammed in several years, which is very rare in sand preparation machines.”

This is also one of the main reasons Jiwei continues to receive praise in the casting industry.

04 Focus of This Visit: Proposing a Higher-Level Upgrade—Dual-Rod Vibrating Rod Level Switch

Although rotary paddles operate stably, as the equipment manufacturer further raised the reliability requirements of the production line, Jiwei engineers evaluated the situation on-site and recommended upgrading key positions to dual-rod vibrating rod level switches (vibrating rod).

Upgrade Reason 1: Dual-Rod Structure More Stable (Many Competitors Use Single Rods)

Competitors generally use single-rod vibrating rods, which easily encounter the following issues under precision sand conditions:

- Rapid vibration attenuation and uneven force distribution;

- Fine sand adhesion reducing vibration amplitude;

- Susceptibility to disturbance under high-pressure blowing.

Jiwei’s dual-rod structure features multiple invention patents, offering higher mechanical strength and more sensitive detection, significantly improving reliability.

Upgrade Reason 2: No Rotating Parts, Completely Solving “Shaft Jamming” Issues

Vibrating rods inherently lack rotating mechanisms, therefore eliminating:

- Wear on rotary seals;

- Sand entering bearings;

- Rotation obstruction caused by dust.

For sand preparation machines, this represents a qualitative leap in reliability.

Upgrade Reason 3: Longer Service Life, Maintenance-Free

Precision sand is highly permeable, and long-term abrasion can damage mechanical structures. The integrated encapsulation of vibrating rods is more robust and reliable, maintaining long-term stability under high-pressure blowing and sand impact, with extended maintenance-free periods.

The customer highly recognized this upgrade plan and plans to perform trial installation and replacement on the next batch of production lines.

05 Conclusion: Jiwei Always Focuses on “Reliability,” Continuously Providing Better Solutions for the Casting Industry

Through this visit, Jiwei and the Suzhou equipment manufacturers further clarified the upgrade path for level measurement under precision sand conditions. Whether it is the long-term stable rotary paddle solution or the newly introduced vibrating rod upgrade plan based on the latest industry needs, Jiwei always adheres to the core value of “reliability”, providing more professional, durable, and long-term stable level measurement solutions for the automotive casting industry.

In the future, Jiwei will continue to explore more automotive parts casting and precision sand scenarios, delivering higher efficiency, safety, and reliability in measurement and control for customers.