Reliable Silo Level Monitoring with Jiwei Radar and Vibrating Rod Level Switches

Industry Background and Application Needs

Wood pellet producers rely on precise storage management to maintain continuous production and meet seasonal demand. Finished pellets are stored in corrugated metal silos exceeding 30 meters in height. To ensure safe silo operation, efficient logistics, and optimized production capacity, two types of instrumentation are typically employed.

Radar level meters provide continuous and reliable measurement across the full silo height, delivering real-time inventory data for production planning and supply chain management. Complementing this, level switches are installed as point level detection devices, offering critical overfill and empty-bin protection to safeguard equipment and prevent material losses. Together, these technologies form an integrated solution that addresses both continuous monitoring and safety control requirements in wood pellet storage.

Challenges in silo storage include:

- Medium: Wood pellets with variable density and size.

- Temperature: -20 … +40 °C, with seasonal fluctuations.

- Pressure: Atmospheric (0 bar).

- Special challenges: High dust levels, highly corrugated walls, and temperature variations.

Traditional capacitive sensors often struggle with dust accumulation, material adhesion, and installation in tall silos. While VEGA products have been widely adopted, Jiwei’s JWrada® radar meters and Tube-11 vibrating rod level switches provide a reliable made-in-China alternative with superior performance, shorter lead times, and strong international export experience.

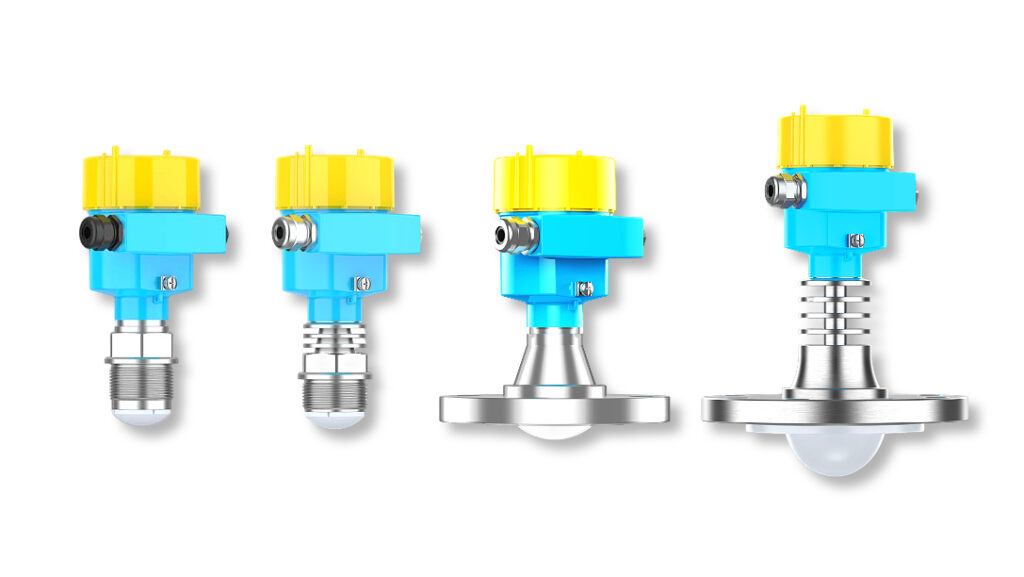

Jiwei JWrada® Radar Level Measurement

Jiwei’s JWrada® radar level meters employ 80GHz FMCW technology, delivering highly accurate continuous level measurement even in complex silo environments. Key advantages include:

- High Accuracy: ±1 mm for liquids, <0.1% for solids, with measuring ranges up to 120 m.

- Smart Connectivity: Built-in Bluetooth 5.0 compatible with the “Jiwei Smart Control” WeChat app for on-site wireless commissioning and monitoring; cloud connectivity allows remote operation.

- Intelligent Echo Processing: Automatically identifies false echoes, separates multiple echoes, and dynamically tracks targets to ensure precise measurement even in dust-laden, foamy, or steam-heavy silos.

- Strong Anti-Interference: Stable readings amid agitation, steam, dust, and electromagnetic disturbances.

- High-Temperature Capability: Operates up to 220 °C, ideal for challenging thermal conditions.

- Explosion-Proof Certified: Approved for gas and dust hazardous areas (Ex db IIC T6 Gb; Ex ia IIC T6 Ga; Ex tb IIIC T80 °C Db; Ex ia IIIC T200 80 °C Da).

- Corrosion-Resistant Design: Robust construction with PTFE-sealed diaphragm ensures reliable operation in acidic or alkaline environments.

- Narrow Beam & Versatile Measurement: Concentrated beam suitable for low-dielectric powders, solid granules, steam, foam, and dusty or vapor-filled atmospheres.

- Versatile Applications: Applicable for liquids, powders, and solid particle level measurement across demanding industrial conditions.

Installed at the top of the silo, JWrada® radar meters provide continuous monitoring of wood pellets, preventing overfill, optimizing material logistics, and enhancing production efficiency.

Jiwei Tube-11 Vibrating Rod Level Switch for Point Detection

For point level detection, Jiwei’s Tube-11 vibrating rod level switches complement radar measurement by providing discrete high- and low-level signals:

- Double-Rod Design: Increases stability, reduces false alarms, and enhances mechanical robustness.

- High Sensitivity: Detects low-density pellets and fine solids with precision.

- High-Temperature Capability: Standard up to 250 °C; optional water or air cooling extends operation to 400 °C.

- Anti-Buildup Performance: Reliable switching despite dust and pellet adhesion.

- Maintenance-Free Operation: No calibration required, unaffected by changes in material properties.

- Safety Certifications: CE, IP66/IP67, flameproof and intrinsic safety approved.

The combination of JWrada® radar and Tube-11 level switches provides a complete monitoring solution for wood pellet silos, ensuring both continuous and discrete level control.

Jiwei as a VEGA Alternative

Jiwei products not only match the performance of VEGA devices but also provide additional advantages:

- Short Delivery Time: 2–5 days for standard units, enabling rapid project deployment.

- Export Experience: Products shipped to multiple countries with smooth customs clearance and logistics.

- Cost-Effectiveness: Competitive pricing without compromising quality or safety.

- Localized Support: Experienced in advising international clients on installation and regulatory compliance.

By choosing Jiwei, biomass facilities gain a reliable, fast-delivery alternative to imported VEGA instruments, without sacrificing accuracy, safety, or durability.

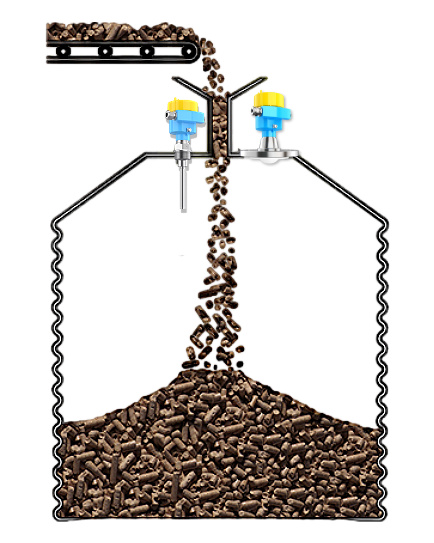

Integrated Silo Monitoring System

A typical installation combines:

- JWrada® radar meter: Continuous measurement of silo contents for inventory and process optimization.

- Tube-11 vibrating rod level switches: High and low level detection to trigger filling or prevent overfilling.

This setup allows operators to:

- Maintain automated production without manual intervention.

- Avoid downtime due to silo overfill or emptying.

- Reduce maintenance costs with wear-free, robust instruments.

- Optimize silo utilization and improve production efficiency.

A European-style pellet plant that implemented JWrada® radar and Tube-11 level switches reported:

- Accurate readings despite dust and corrugated walls.

- Reduced false alarms compared to older capacitive sensors.

- Longer maintenance intervals, lower operating costs, and improved throughput.

Operators confirmed that this combined solution is reliable, cost-effective, and ideal for automated production, proving a long-term alternative to VEGA.

Conclusion

Wood pellet silos require precise level measurement and point detection in challenging conditions such as dust, corrugated walls, and temperature fluctuations. Jiwei’s integrated solution—JWrada® radar meters and Tube-11 vibrating rod level switches—offers:

- High-accuracy, maintenance-free operation.

- Superior anti-buildup and dust tolerance.

- Temperature resilience up to 400 °C with cooling.

- Fully certified, safe, and durable instruments.

- Fast delivery and smooth international export—short lead times and expert customs support.

For biomass facilities seeking a reliable, cost-effective, and rapid-deployment VEGA alternative, Jiwei provides the ideal solution—designed and manufactured in China, with global-standard performance and durability.