Smart Level Measurement Solutions for Beer Brewing: Jiwei’s Radar and Tuning Fork Technologies

Beer Brewing Process

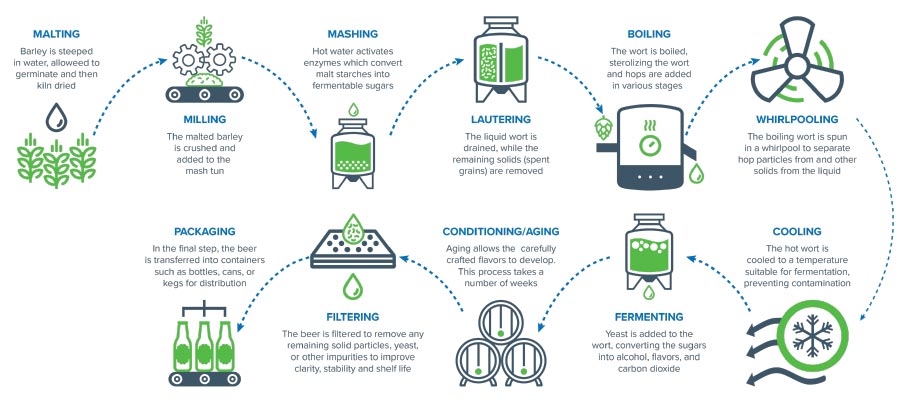

Do you enjoy drinking beer? Nowadays, the “Morning C, Evening A” lifestyle has become a norm for many urban dwellers. Whether paired with hotpot, barbecue, or a casual drink with friends, beer is an indispensable companion. But have you ever wondered how beer transforms from a single grain of malt into the refreshing liquid in your glass? Today, let’s explore the beer brewing process.

Beer Brewing Technology

The beer production process involves critical stages such as raw material crushing, mashing, filtration, boiling, cooling, fermentation, storage, filling, and CIP (Clean-In-Place) cleaning. As modern brewing equipment evolves towards larger capacities and intelligent automation, accurate and reliable process instrumentation is essential for ensuring safety and stability throughout the brewing workflow.

Shenzhen Jiwei Automations Ltd.’s core products—including the JWrada® radar level meter, Ring-11 tuning fork level switch(for liquids only), Ring-21 mini tuning fork level switch, and Tube-11 vibrating rod level switch—feature proprietary technologies and industry-leading designs. These instruments are widely applied throughout the beer brewing process for precise liquid and material level monitoring, ensuring optimal operation at every step.

1. Raw Material Crushing – Level Limit Monitoring for Equipment Protection

After malt is stored in raw material bins, it is fed into crushers for milling. Crushers require continuous feeding to avoid empty running, which causes excessive mechanical wear and potential failure.

Jiwei’s Tube-11 vibrating rod level switch adopts a patented dual-rod design—the first of its kind domestically—with technical parameters comparable to top imported brands. It features excellent dust resistance and mechanical vibration immunity, reliably providing level limit detection within material bins. Its compact structure and versatile mounting options adapt well to complex crushing environments, effectively preventing empty running and extending crusher lifespan.

2. Mashing and Filtration – High-Frequency Radar Continuous Level Measurement Ensures Enzymatic Reaction

The malt mash is heated in the mashing kettle, where endogenous enzymes convert starch into soluble maltose. This stage involves frequent dynamic liquid level changes and a harsh environment with high-temperature steam and foam interference.

Jiwei’s JWrada® radar level meter uses 80 GHz high-frequency millimeter-wave technology, with an extremely narrow beam angle and zero blind zone design. It penetrates steam and foam effectively, enabling highly sensitive, non-contact continuous level measurement. Built-in intelligent signal processing algorithms enhance anti-interference performance, ensuring stable and accurate level measurement in the mash tun—crucial for precise temperature and volume control during mashing.

3. Boiling with Hops – Dual Level and Limit Monitoring for Process Stability

During boiling, wort is mixed with hops, and precise liquid level control directly impacts beer flavor and quality. The timing and quantity of hops addition must be strictly controlled.

Jiwei’s Ring-11 and Ring-21 tuning fork level switches monitor the high and low limit positions of the hop addition apparatus, ensuring reliable device operation. Simultaneously, the JWrada® radar level meter continuously monitors liquid level in the boiling kettle, providing real-time insight into liquid surface dynamics to guarantee safe, stable boiling and consistent beer flavor.

4. Cooling and Fermentation – Multi-Parameter Intelligent Monitoring Ensures Fermentation Safety

After cooling, the wort enters fermentation tanks, requiring maintenance of optimal 8–15°C temperatures and monitoring of pressure and liquid level to ensure yeast viability and fermentation stability.

JWrada® radar level meters employ non-contact continuous measurement technology to accurately reflect fermentation tank liquid levels. Intelligent algorithms identify and filter CO₂ bubble interference signals, guaranteeing reliable data. Ring-11 tuning fork level switches provide safety protection by detecting high and low liquid level limits, preventing abnormal levels from disrupting fermentation. Pressure sensors complement the system by monitoring CO₂ pressure, creating a multidimensional intelligent control framework.

5. Storage and Filling – Hygienic Design Ensures Quality and Efficiency

Mature beer is stored in tanks where foam presence requires liquid level monitoring that compensates for foam influence to maintain high accuracy. The filling process demands stringent empty tank protection.

JWrada® radar level meters are equipped with process connections compliant with international food hygiene standards. Their corrosion-resistant, easy-to-clean measuring elements ensure accurate level data while meeting sanitary requirements. Ring-11 tuning fork level switches detect empty tanks and trigger limit alarms during filling, guaranteeing continuous and stable filling operations and preventing equipment dry-running losses.

6. CIP Cleaning – High-Temperature Water-Cooled Structure Enhances Corrosion Resistance and Stability

The Clean-In-Place (CIP) process involves using high-temperature strong alkaline or acidic cleaning solutions, posing stringent demands on instrument temperature tolerance and corrosion resistance.

Jiwei’s Ring-11 tuning fork level switch boasts up to 400°C temperature resistance with advanced water-cooling technology—leading domestically in this design—ensuring core electronics operate stably under extreme conditions. Sanitary process connections comply with food-grade cleaning standards, and the instruments withstand long-term exposure to highly corrosive media, securing safe and efficient cleaning operations.

Individual Use and Combined Application Advantages

- JWrada® Radar Level Meter specializes in continuous liquid level measurement, ideal for mashing tuns, fermentation tanks, storage tanks, and CIP vessels. Its non-contact design minimizes maintenance needs and enhances measurement stability.

- Tube-11 Vibrating Rod Level Switch primarily provides high and low limit alarms and equipment protection, suitable for material bins, conveyors, and harsh high-temperature corrosive environments.

- When used together, these instruments offer dual-layer protection: continuous measurement combined with limit detection. This synergy elevates automation intelligence and ensures safety and efficiency across the beer production process.

Jiwei’s JWrada® radar level meter, Ring-11 tuning fork level switch, Ring-21 mini tuning fork level switch, and Tube-11 vibrating rod level switch represent a highly integrated and reliable instrumentation portfolio. Their advanced technologies provide precise measurement assurance at every key stage of beer brewing, supporting brewers in achieving automation upgrades and consistent product quality