PLC Communication Methods in Industrial Automation: An In-Depth Overview

In industrial automation, the Programmable Logic Controller (PLC) serves as the core component connecting devices to production systems, playing a crucial role in control and monitoring. The communication method of a PLC directly influences the efficiency and stability of data exchange. With evolving industrial demands and advances in communication technology, PLC communication methods have diversified to meet various industry requirements for real-time performance, stability, and reliability.

This article provides a comprehensive exploration of common PLC communication methods, including traditional serial communication, fieldbus, industrial Ethernet, wireless communication, and cross-platform protocols, helping readers understand their characteristics and application scenarios.

1. Traditional Serial Communication: A Simple and Reliable Starting Point

RS-232 Communication

RS-232 is one of the most basic serial communication protocols, suitable for direct connection between two devices. It uses three wires (TX, RX, GND) for bidirectional data transmission, typically supporting speeds up to 115.2 kbps with a maximum distance around 15 meters (per EIA-232 standard). Although simple, RS-232 remains practical for basic communication needs.

Application Example: In a food packaging system, engineers used RS-232 to connect the PLC to an HMI for real-time packaging speed display. This method suits short-distance, low-speed data exchange but is limited by bandwidth and range.

RS-485 Communication

RS-485 improves upon RS-232 by supporting multipoint communication with up to 32 devices (per TIA/EIA-485 standard). It employs differential signaling to enhance noise immunity and supports data transmission over longer distances up to 1200 meters. RS-485 is often paired with Modbus RTU protocol for relatively simple control scenarios.

Application Example: In a chemical plant, engineers connected multiple PLCs and sensors via RS-485 to build a distributed temperature monitoring system, benefiting from its robustness in harsh industrial environments.

2. Fieldbus Communication: The Backbone of Large-Scale Workshops

PROFIBUS Communication

PROFIBUS, promoted by Siemens, is a fieldbus protocol with data rates up to 12 Mbps, typically using token-passing for network access control. It excels in real-time data exchange and often adopts linear or branched topologies.

Application Example: An automotive assembly plant connected over 200 devices via PROFIBUS to enable real-time monitoring of the welding process, ensuring low-latency system responses and precise process control.

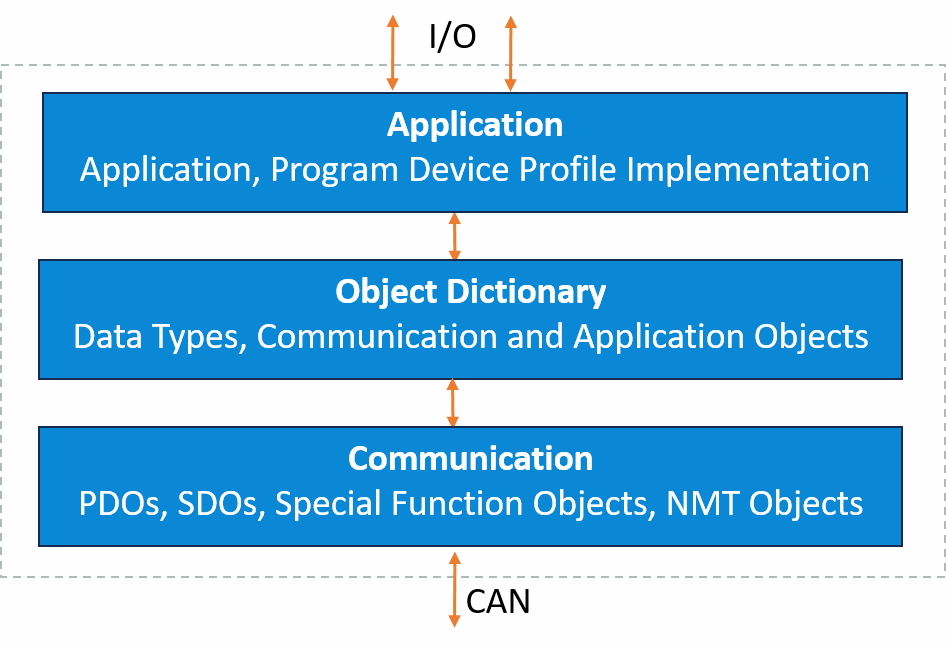

CANopen Communication

Based on the CAN (Controller Area Network) protocol, CANopen offers high noise immunity and reliability with speeds up to 1 Mbps (ISO 11898 standard). It is widely used in environments with strong electromagnetic interference such as heavy machinery or transportation systems.

Application Example: In a subway system, CANopen supports train signal control, ensuring high system reliability and minimal failure rates under complex conditions.

3. Industrial Ethernet Communication: High-Speed Real-Time Data Backbone

PROFINET Communication

PROFINET, an industrial Ethernet protocol, supports both Real-Time (RT) and Isochronous Real-Time (IRT) communication modes. It achieves response times as low as 0.5 ms and can handle thousands of nodes. Its high bandwidth and low latency make it ideal for applications requiring high synchronization and precision.

Application Example: In a semiconductor fab, PROFINET in IRT mode managed over 300 devices with microsecond-level synchronization, ensuring efficient wafer handling.

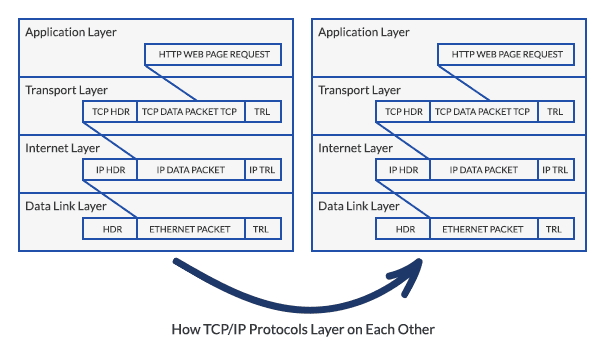

EtherNet/IP Communication

EtherNet/IP is built on TCP/IP and supports the Common Industrial Protocol (CIP). Although slightly less real-time than PROFINET (typical latency around 10 ms), its openness and compatibility suit applications such as packaging and material handling.

Application Example: In a smart logistics warehouse, EtherNet/IP enabled PLC communication with sorting conveyors to quickly relay orders and equipment commands, meeting high throughput and complexity requirements.

4. Wireless Communication: Flexible Solutions Beyond Wired Constraints

Industrial WiFi Communication

Based on WLAN technology, industrial WiFi supports dense device connections, especially with WiFi 6’s MU-MIMO capabilities for multi-device concurrency. However, wireless signals can be susceptible to interference, affecting transmission stability in some environments.

Application Example: Over 200 automated guided vehicles (AGVs) in a logistics center connect via WiFi, maintaining millisecond-level data update cycles and improving transport efficiency.

5G Communication

5G offers ultra-high bandwidth and ultra-low latency (under 1 ms), supporting massive industrial device connectivity. It is ideal for smart factories, remote control, and real-time monitoring scenarios, enabling applications such as autonomous vehicles and remote operation.

Application Example: A coal mine deployed a 5G industrial network to manage autonomous mining trucks and integrate high-definition video monitoring with less than 8 ms latency, significantly enhancing system stability and operational efficiency.

5. Cross-Platform Communication: Bridging Heterogeneous Device “Language” Barriers

OPC UA Communication

OPC UA (Unified Architecture) is a cross-platform, brand-agnostic industrial communication standard enabling secure, efficient data exchange between PLCs and factory software. It supports XML and binary data encoding and features built-in security mechanisms.

Application Example: In a smart water management system, OPC UA integrated data from ABB and Siemens PLCs, uploading it to cloud platforms for remote analysis and control, solving multi-brand data compatibility issues.

MQTT Protocol

MQTT is a lightweight publish/subscribe protocol ideal for bandwidth-limited environments and supports remote monitoring and edge computing. Its low bandwidth and efficient data transmission make it popular in IoT applications.

Application Example: In a smart factory in Fujian, MQTT uploads production data to the cloud, enabling managers to monitor production status and energy consumption via mobile devices in real-time.

Summary: How to Choose the Right PLC Communication Method?

Different communication methods suit different application needs and environments. The following comparison can help guide your choice:

| Communication Type | Max Data Rate | Max Distance | Noise Immunity | Typical Use Case |

|---|---|---|---|---|

| RS-232 | 115.2 kbps | 15 m | Low | Simple short-distance communication |

| RS-485 | 10 Mbps | 1200 m | Medium | Small to medium distributed systems |

| PROFIBUS | 12 Mbps | 100 m | High | Large scale, real-time industrial setups |

| PROFINET | 100 Mbps – 1 Gbps | N/A | High | High-speed precision control systems |

| Industrial WiFi | 9.6 Gbps (WiFi 6) | ~100 m (good signal) | Medium | Mobile devices, intelligent AGVs |

| 5G | >1 Gbps | Varies | High | Remote control, autonomous vehicles |

| OPC UA | Variable | Cloud-based | High | Multi-platform heterogeneous systems |

Selecting the appropriate communication method improves production efficiency, reduces costs, and optimizes overall industrial automation performance.