Why Radar Level Meters Are Replacing Ultrasonic Level Meters?

Introduction

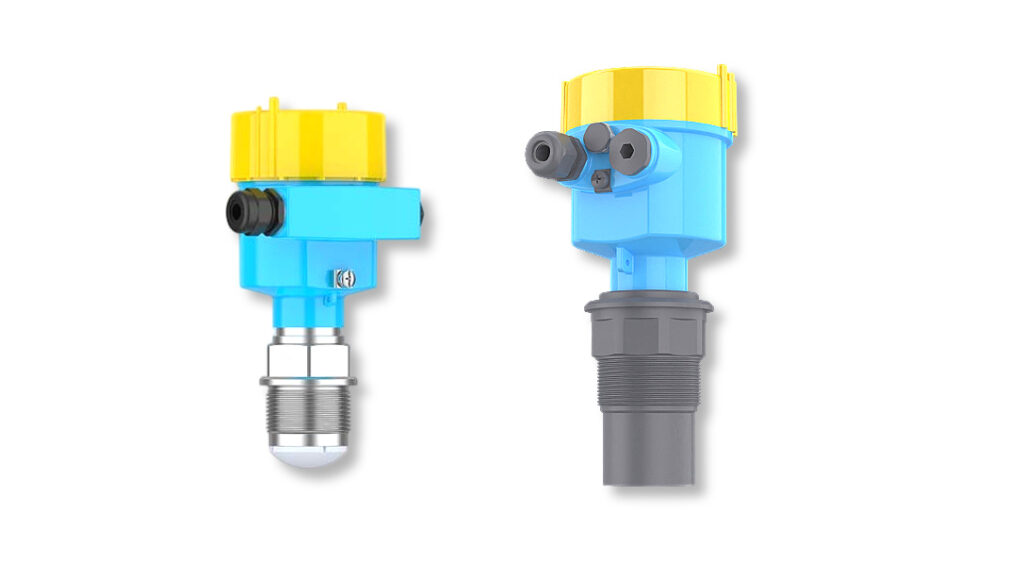

Ultrasonic level meters have long been widely used across many industries due to their non-contact and reliable measurement capabilities. However, with increasingly complex working conditions and rising demands for intelligent monitoring, more and more companies are opting to replace ultrasonic devices with radar level meters. This trend is especially prominent in industries like petrochemical, power generation, pharmaceuticals, food processing, and water treatment, where measurement stability and accuracy are critical.

This article systematically compares radar and ultrasonic level meters across key aspects such as measurement principles, environmental suitability, accuracy, interference resistance, cost-effectiveness, and installation and maintenance, offering practical guidance for industrial applications.

Radar Level Meter vs Ultrasonic Level Meter

Measurement Principle Difference: Electromagnetic Waves vs Sound Waves

Ultrasonic level meters use sound waves to calculate liquid levels by sending high-frequency ultrasonic pulses and measuring their echo time. However, ultrasonic waves are highly susceptible to environmental factors such as temperature fluctuations, steam, air pressure, and dust, which can distort or weaken the signal.

Radar level meters, on the other hand, utilize electromagnetic waves (microwaves) for measurement. The recent widespread adoption of 80 GHz Frequency Modulated Continuous Wave (FMCW) radar level meters brings advantages including narrower beam angles, stronger signal penetration, and faster response times. Since electromagnetic wave propagation does not depend on the air medium, radar meters perform better under harsh industrial conditions.

Superior Environmental Adaptability of Radar Level Meters

- High Temperature and Pressure:

Ultrasonic meters typically operate under ambient temperature and pressure. Radar meters can easily handle extreme conditions up to 220°C and 40 bar, making them ideal for steam boilers and reactors. - Steam and Foam Interference:

Ultrasonic sensors often lose signal due to steam, foam, and condensation. Radar meters leverage electromagnetic wave penetration to deliver stable measurements even amid foam, steam, and high humidity. - Dust and Volatile Gases:

In environments such as grain silos and cement storage with dense dust, ultrasonic sensors may accumulate dust on their surface, affecting signal emission and reception. Radar meters equipped with sealed antennas and air purging systems ensure long-term reliable operation.

Measurement Accuracy and Stability: Radar Precision up to ±1mm

Ultrasonic level meters typically achieve ±5 to ±10 mm accuracy and are sensitive to environmental changes. In contrast, modern high-frequency radar meters (such as 80 GHz) reach accuracies within ±1 mm. Their advanced dynamic signal processing algorithms accurately identify true echoes despite liquid surface agitation, waves, or turbulence.

Installation and Maintenance Advantages of Radar Level Meters

- Flexible Installation:

Narrow radar beam angles (~3°) allow installation that avoids mixers and obstacles, suitable for confined or complex tank geometries. - Low Maintenance:

Radar meters typically feature fully sealed designs with no moving parts, resisting fouling and reducing maintenance frequency. - Smart Diagnostics:

Support for remote calibration, condition monitoring, and integration with DCS or PLC systems facilitates intelligent plant management.

Cost and ROI: Radar Meter Prices Fall, Return on Investment Improves

Historically, radar meters were expensive and posed a barrier to adoption. However, with increasing domestic production and maturing technologies, cost-effective Chinese radar meters (such as Jiwei’s JWrada® series) now rival imported products in quality and outperform traditional ultrasonic devices in cost-effectiveness.

In challenging environments with frequent liquid level fluctuations, ultrasonic meters often require costly maintenance and cause downtime. Radar meters provide long-term stable operation and lower total cost of ownership (TCO).

Real-World Cases: Successful Replacement of Ultrasonic Meters with Radar

At a major power plant’s desulfurization tower, ultrasonic meters suffered frequent signal loss due to condensation and temperature swings, compromising precise chemical dosing. After switching to 80 GHz radar meters, measurement signals stabilized, responses accelerated, and liquid level control improved significantly, winning strong customer approval.

Similarly, in a municipal wastewater treatment plant’s aeration basin, radar meters successfully penetrated surface foam and gas layers, enabling continuous level monitoring and reliable pump station control.

Summary: Radar Level Meters Are the Inevitable Next Step in Technological Upgrade

| Feature | Ultrasonic Level Meter | Radar Level Meter (Especially 80 GHz) |

|---|---|---|

| Measured Medium | Liquids (requires clean, steam-free) | Liquids, solids, slurry, foam, steam |

| Interference Resistance | Weak, environment sensitive | Strong, suitable for harsh conditions |

| Accuracy | ±5 to ±10 mm | ±1 mm |

| Installation Flexibility | Wide beam angle, prone to interference | Narrow beam angle, flexible installation |

| Maintenance Cost | Frequent maintenance and calibration | Maintenance-free, remote smart diagnostics |

| Initial Cost | Low | Moderate (rapidly decreasing) |

| Applicable Industries | Wastewater, food processing | Petrochemical, power, pharmaceuticals, cement, grain storage |

Recommendation

For companies still relying on ultrasonic meters, especially in environments with high temperatures, steam, foam, and dust, upgrading to high-frequency radar meters is a clear choice. This switch enhances measurement accuracy and reliability while reducing downtime and maintenance expenses.

With continuous technological advances and the rise of domestic brands like Jiwei Automations’ JWrada® series, radar meters are no longer a costly luxury but a smart investment for future-proof industrial automation.

For more information on radar level meter solutions tailored to your industry or application, please contact our technical support to receive the latest technical data and case studies.

radar level meter, ultrasonic level meter, industrial liquid level measurement, 80 GHz FMCW radar, measurement accuracy, harsh environment level measurement, Jiwei Automations, JWrada radar, intelligent liquid level control, level meter replacement