How JWrada®-35 Radar Level Meter Ensures Reliable Level Measurement in Reflux Accumulator Drums

Project Background and Unit Overview

In continuous distillation processes, the reflux system is one of the core units determining separation efficiency and energy consumption. The reflux accumulator drum, as a key buffer device after the top condenser, temporarily stores condensed liquid, further separates gas and liquid, and distributes liquid for reflux or product withdrawal. Accurate and reliable measurement of the drum’s liquid level using a radar level meter directly ensures stable reflux ratio control, which in turn affects tray efficiency, theoretical plate utilization, and product purity.

This case comes from a fine chemical company in Zhengzhou operating a continuous distillation unit for aromatic solvents. The unit runs year-round, with a wide range of design load variations and very high requirements for top-of-column operation stability. As the unit ages, the original reflux accumulator drum level measurement scheme has gradually revealed inadequate adaptability, becoming a weak point limiting stable operation.

Reflux Accumulator Drum Conditions and Measurement Challenges

The reflux accumulator drum is located after the top condenser, representing a typical high-demand level measurement scenario. The specific conditions are as follows:

- Medium Characteristics: Organic solvent mixture condensed from top vapor, with low dielectric constant and variation depending on composition.

- Temperature Conditions: Normal operating temperature is approximately 90–120 °C, with short-term high-temperature surges during unit startup, shutdown, and process switching.

- Pressure Conditions: Slightly positive pressure; internal pressure fluctuates with condensate load, synchronizing with liquid level.

- Process Characteristics:

- Reflux ratio frequently adjusted according to product specifications

- Reflux pump highly sensitive to liquid level stability

- Level changes are small in amplitude but frequent

- Condensate entering the drum easily disturbs the liquid surface, occasionally accompanied by foam

These conditions require that level measurement is not only accurate, but also stable, continuous, and reliable over long-term operation.

Problems with the Original Measurement Scheme

Initially, the reflux drum level was measured using a traditional differential pressure (DP) level meter. While widely used in conventional liquid storage tanks, its limitations became apparent under reflux drum conditions:

- Dependence on Medium Density: DP meters rely on a stable medium density. In the reflux drum, condensate composition is complex, and temperature fluctuates with operating conditions and condenser load, causing significant density variations. Since the DP signal-to-level conversion is based on a fixed density, the actual liquid level often deviates from the displayed reading. In severe cases, the discrepancy can reach several centimeters, directly affecting precise reflux ratio control.

- Limited Long-Term Stability: The zero point of DP meters drifts due to temperature cycles, piping stress, and long-term use, requiring regular manual calibration. Each calibration increases maintenance costs and requires special operational management to avoid safety hazards and production fluctuations caused by inaccurate readings. For a continuously operating distillation column, this adds management burden and potential shutdown risk.

- Lag in Dynamic Response: During dynamic operation, DP meters respond slowly. Adjusting the reflux ratio usually must occur within a short time to stabilize top temperature and column load. The meter’s response lag delays liquid level feedback to the reflux pump, indirectly reducing separation efficiency.

- Amplified Operational Risk Due to Signal Instability: Under certain conditions, low readings may cause the reflux pump to cavitate, while high readings may lead to overflow or top-level flooding, increasing safety risks and potential equipment damage.

Combined, these issues make traditional DP level meters insufficient to meet the strict requirements of continuous, precise, and reliable level measurement for the reflux drum, limiting stable operation and efficient separation in the distillation unit.

Level Measurement Optimization Approach

Based on the problems revealed by the DP level meter in the reflux drum, the owner defined the following core requirements for the new measurement solution during the technical retrofit design stage:

- Measurement Principle Independence: The liquid level measurement must minimize the influence of medium density, temperature, and pressure variations, ensuring stable and accurate level signals even when condensate composition, temperature, or pressure fluctuate.

- Suitability for Continuous Operation: The measurement method should be compatible with continuous distillation operation, offering long-term stability, reducing maintenance and calibration frequency, minimizing production interference, and improving operational reliability.

- DCS Compatibility: Level output signals must meet real-time and stability requirements of the DCS reflux control system, providing high-precision, continuous, and traceable data for the reflux pump and related control loops.

After thoroughly analyzing the reflux drum’s operating conditions and control requirements, the project team evaluated multiple level measurement solutions, including DP meters, float switches, guided-wave radar, and high-frequency non-contact radar. Considering temperature adaptability, response to medium density variation, maintenance cost, dynamic response, and DCS compatibility, the team ultimately selected the JWrada®-35 radar level meter for continuous level measurement of the reflux drum. This meter not only overcomes the instability of traditional DP meters under complex conditions, but also provides reliable, continuous, and accurate level data for long-term operation, supporting reflux ratio adjustment and top-of-column control.

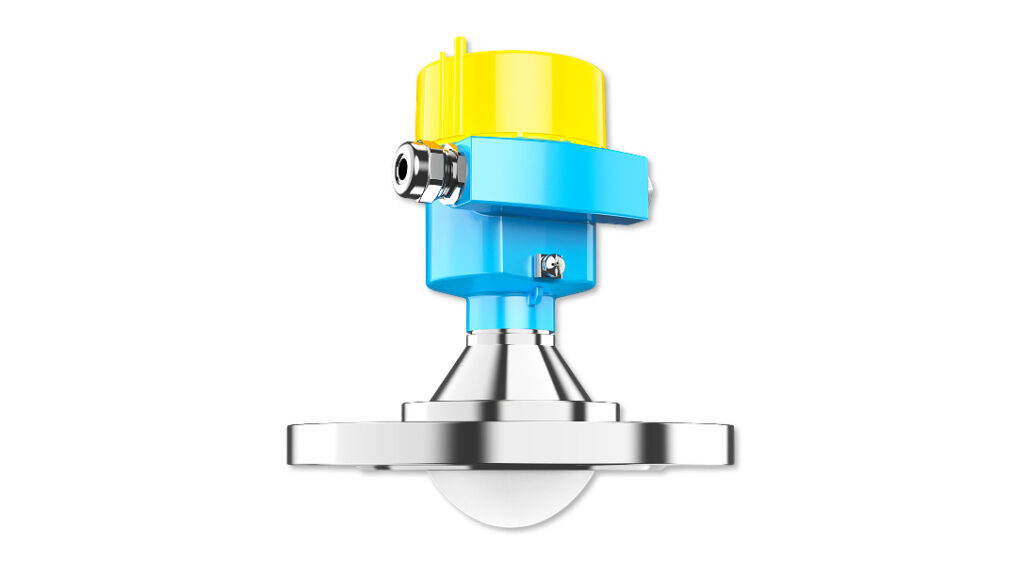

Technical Solution of JWrada®-35 Radar Level Meter

The Jiwei JWrada®-35 adopts FMCW (Frequency Modulated Continuous Wave) radar technology, emitting high-frequency electromagnetic waves and receiving reflected echoes from the liquid surface to calculate liquid level. Its advantages include:

- Unique software capabilities: software updates, process debugging, parameter setting, fault code monitoring

- Engineers can perform real-time remote tuning with on-site personnel via cloud server, viewing and analyzing echo and EFT curves

- All functions are independently developed by Jiwei, with no similar solutions currently available from domestic manufacturers

- Non-contact measurement, unaffected by corrosion, scaling, or process contamination

- Independent of medium properties; minimally affected by density, viscosity, or temperature variations

- Suitable for low dielectric constant media, ideal for organic solvent condensate

- High signal stability, suitable for frequent but small-amplitude level changes

In this project, the JWrada®-35 was top-mounted with a high-gain antenna for small-diameter nozzles, ensuring clear and reliable echoes despite internal structures and vapor disturbances.

Installation, Commissioning, and Parameter Optimization

During installation, the internal flow paths, inlet/outlet locations, and potential false echo sources were carefully considered. After installation, the following steps were completed:

- Establishing echo learning curves to differentiate true liquid echoes from internal structure reflections

- Setting appropriate measurement range and blind zone parameters

- Optimizing signal filtering and damping to improve output stability

- Connecting the 4–20 mA signal to the DCS for reflux control and level interlocking

Commissioning results showed that even under load fluctuations and variable condensate flow, the level signal remained continuous and smooth, with no sudden jumps.

Operational Results and Engineering Value

After deployment of JWrada®-35, the reliability of reflux drum level measurement significantly improved:

- Long-term stable level signal with minimal drift

- Improved reflux pump operation; no cavitation issues

- Smoother reflux ratio control; reduced top temperature fluctuations

- Enhanced overall distillation column separation efficiency and product quality stability

The owner reported that the radar level meter effectively eliminated measurement uncertainty, providing critical data support for long-term, stable, and efficient distillation operation.

Case Summary

Although the reflux drum is an auxiliary device in the distillation unit, its level measurement directly affects top-of-column operation and separation performance. Introducing the JWrada®-35 radar level meter successfully resolved the instability issues of traditional measurement methods under complex conditions.

This case demonstrates that, for distillation units with extremely high continuity and stability requirements, employing a mature and reliable radar level measurement solution is an essential technical measure to ensure precise reflux system control and improve overall process efficiency.