JWrada® Radar Level Meter for Intermediate Tanks under Corrosive and Foaming Conditions

I. Project Background and Industry Conditions

In the production of fine chemicals, pharmaceutical intermediates, and some new energy materials, corrosive liquids accompanied by significant foam generation represent a very typical yet highly challenging operating condition. This type of condition is commonly found in post-reaction buffer tanks, intermediate storage tanks, gas-liquid separation tanks, and washing tower circulation tanks, where the reliability of level measurement directly affects process stability and plant safety.

The Ningbo fine chemical facility produces high-value-added organic chemicals. After the reaction is completed, the material enters an intermediate holding tank (Intermediate Holding Tank) for temporary storage, degassing, and continuous downstream transfer. This tank has long been characterized by highly corrosive media, a persistent foam layer, and frequent process fluctuations, making liquid level measurement a challenging aspect of plant operation.

II. Tank Structure and Specific Operating Conditions

The equipment is a vertical cylindrical carbon steel tank lined with PTFE, with a volume of approximately 12 m³. The top is equipped with a feed inlet, vent port, and instrument connection, while the bottom connects to a transfer pump. Its main operating characteristics are as follows:

Medium Characteristics

- The material is a mixture of organic acids and solvents, highly corrosive, with strict requirements for metal and sealing materials.

- Residual surfactants from the reaction lead to persistent foam generation on the liquid surface.

Foam Characteristics

- Foam layer thickness is unstable, typically fluctuating between 100–300 mm.

- Foam is low-density and loosely structured but can cover the true liquid surface.

Temperature and Pressure

- Operating temperature ranges from approximately 70–95 °C year-round.

- Operates at atmospheric or slightly positive pressure.

Process Requirements

- Level is used for interlock control of the transfer pump.

- Prevent tank overflow and pump cavitation.

- Signal must be continuous and stable, with no frequent false alarms.

III. Issues with the Original Measurement Solution

Initially, the intermediate tank adopted a submersible level meter with a corrosion-resistant sleeve. However, during long-term operation, this scheme gradually revealed multiple issues.

Firstly, foam significantly interfered with measurement. During operation, the liquid surface in the intermediate tank was persistently covered by foam, causing the submersible probe to be enveloped by foam. This led to pressure transmission distortion, frequent signal fluctuation and drift, and poor measurement stability.

Secondly, corrosive media accelerated sensor aging. Even with corrosion-resistant materials and protective sleeves, the sensor diaphragm inevitably aged under highly corrosive conditions, leading to gradual zero-point drift. Instruments required regular calibration or replacement, increasing maintenance frequency and cost.

Additionally, cleaning and scaling affected long-term stability. During periodic cleaning or process switching, instruments often needed to be removed or recalibrated, which increased on-site maintenance workload and disrupted continuous production.

Finally, false alarms were frequent. When foam rapidly increased or process conditions fluctuated, the level signal often jumped abnormally, triggering false level alarms and pump stops, affecting normal operation.

The combination of these issues made level measurement a weak link in stable operation and the main motivation for optimizing the measurement scheme.

IV. Measurement Scheme Optimization Approach

In response to these issues, the owner clearly defined three core requirements during the technical retrofit:

- The measurement method must avoid direct contact with corrosive media and foam.

- Level signals must not be affected by frequent foam layer fluctuations.

- The method must support continuous operation while reducing maintenance and manual intervention.

After evaluating multiple solutions including float, guided-wave radar, differential pressure, and high-frequency radar, the JWrada® series FMCW radar level meter was ultimately selected for continuous level measurement under this corrosive and foaming operating condition.

V. Technical Solution of the Radar Level Meter

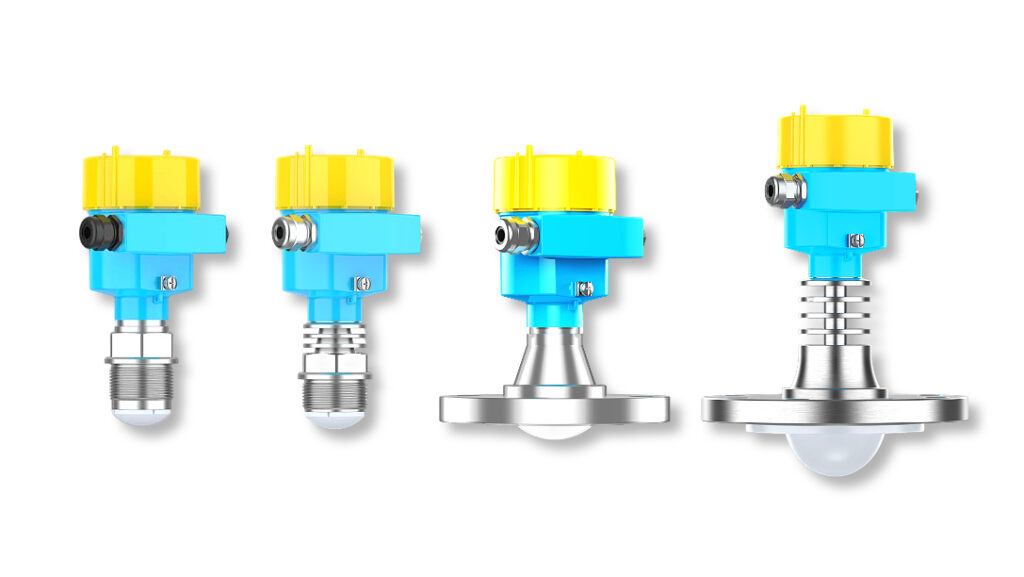

The Jiwei JWrada® series radar level meter was selected as the intermediate tank level measurement solution due to its stability and long-term reliability under corrosive and foaming conditions. The instrument has been systematically optimized in terms of measurement principle, structural design, and software system for complex chemical process conditions.

In terms of measurement principle, the JWrada® radar level meter uses FMCW (Frequency Modulated Continuous Wave) radar technology. It emits high-frequency electromagnetic waves and analyzes frequency-difference echo signals to accurately identify the true liquid surface. Compared with pressure-based or contact measurement methods, this principle does not rely on medium density or physical properties and is highly adaptable to foam, surface fluctuations, or disturbances. Even when foam thickness and form vary during reaction stages, the instrument can reliably distinguish between foam reflection and the true liquid surface, avoiding signal overestimation or drift.

Structurally, the instrument adopts a non-contact measurement design. The radar antenna does not come into direct contact with the medium, fundamentally preventing corrosion of the sensor body and eliminating long-term effects of scaling or contamination on measurement accuracy. This significantly reduces maintenance frequency and spare parts consumption, making it particularly suitable for continuous operation and tanks with short cleaning cycles.

For conditions where foam and surface disturbances coexist, the JWrada® radar level meter combines echo learning mechanisms and signal recognition algorithms to distinguish and suppress reflections from tank structures, feed disturbances, and foam layers, maintaining continuous and smooth level signals. This feature is critical in intermediate tanks with frequent minor level fluctuations, effectively preventing false alarms and interlock actions.

Regarding reliability, the radar level meter has no mechanical moving parts, avoiding diaphragm aging and zero-point drift. Its long-term operational stability significantly exceeds that of submersible or float-type instruments, meeting the management requirements of year-round continuous operation in chemical plants.

In this project, the instrument is top-mounted with a high-performance antenna designed for small-diameter nozzles, ensuring clear and stable echoes even in limited installation spaces.

Additionally, the JWrada® radar level meter has a complete software system, including software updates, process debugging, parameter setting, and fault code monitoring. Through a cloud server, engineers can remotely perform one-to-one commissioning with on-site personnel, view and analyze echo and EFT curves in real time, enabling rapid diagnostics and parameter optimization. These software functions are independently developed, offering significant differentiation compared to domestic products and providing higher maintainability and technical support for subsequent operation.

VI. Installation, Commissioning, and Parameter Optimization

During on-site commissioning, the following tasks were completed:

- Established echo learning models to filter out tank structures and foam interference.

- Optimized echo filtering and damping parameters to improve signal smoothness.

- Set appropriate high and low level alarm points, interlocked with pumps.

- Connected the 4–20 mA signal to the DCS for continuous monitoring.

After commissioning, even under rapid foam generation or dissipation, the level curve remained continuous and free of jumps.

VII. Operational Results and Engineering Value

After deployment, the radar level meter operation gradually stabilized, and measurement effectiveness was confirmed.

Under continuous production, the level signal remained consistent with no noticeable drift over long-term operation. The liquid level accurately reflected tank conditions, with continuous and smooth signal output. As a result, pump operation improved, with no false stops or cavitation events due to inaccurate level measurement.

Moreover, with more reliable level control, the risk of tank overflow was effectively mitigated, enhancing operational safety margins. Compared with the original measurement solution, daily maintenance and calibration workload was significantly reduced, with minimal on-site intervention required due to measurement issues.

The owner concluded that the radar level meter effectively resolved long-standing issues under corrosive and foaming conditions, including unstable measurement, low reliability, and frequent maintenance, providing reliable data support for continuous, stable, and safe operation.

VIII. Case Summary

Under operating conditions where corrosive media coexist with foam, traditional contact-based level measurement methods often fail to ensure reliability and long-term stability. By implementing the JWrada® radar level meter, continuous and stable level measurement of the intermediate reaction tank was successfully achieved.

This case demonstrates that in complex chemical process conditions, selecting an appropriate radar level measurement solution is a crucial technical measure for improving operational reliability, reducing maintenance costs, and ensuring safe production.