Dual-Rod Vibrating Level Switch Solutions for Lithium Battery Anode Material Storage and Handling

Measurement Difficulties in Lithium Battery Anode Material Storage

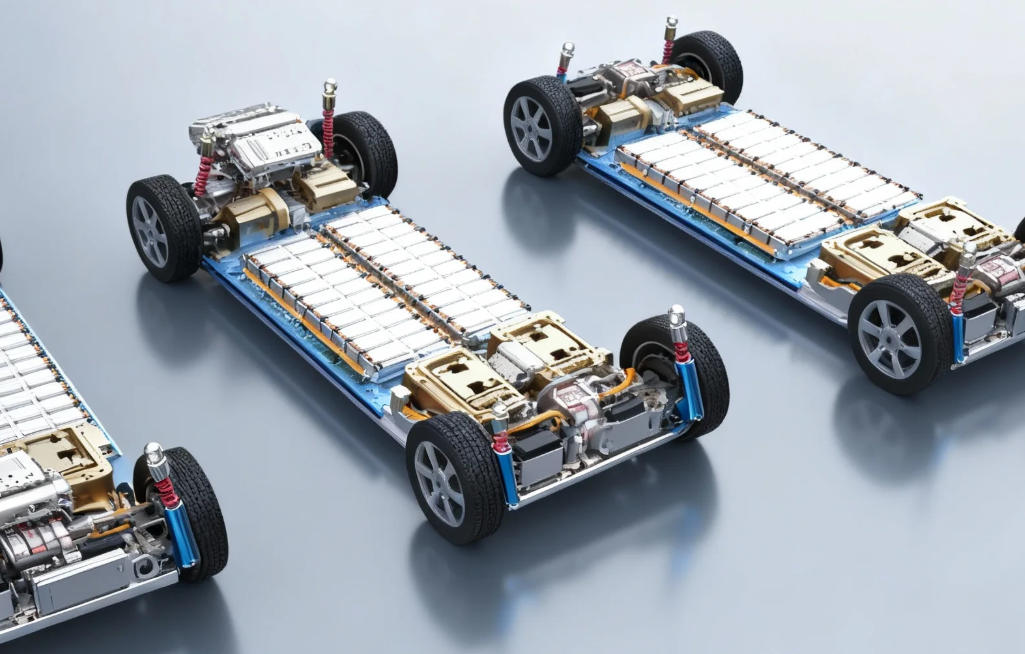

In the lithium battery industry chain, anode material production is a typical powder engineering process. Whether conventional artificial graphite or emerging silicon–carbon composite materials are involved, dual-rod vibrating level switch solutions are required to meet the stringent demands these material properties place on reliable level measurement.

During the expansion of a ten-thousand-ton anode material production line, a new energy company in Suzhou encountered persistent problems with level measurement reliability in material silos. Ensuring stable and accurate level detection became a long-standing challenge for onsite engineers.

Anode materials usually have particle sizes in the micrometer range. Such ultra-fine powders exhibit strong adhesion during pneumatic conveying and mixing processes. Traditional measuring devices, such as rotary paddle level switches, often fail due to insufficient motor torque or blade jamming. Conventional tuning fork switches may also suffer from material accumulation between the forks, leading to frequent false alarms.

An even more critical issue is static electricity. Graphite is inherently conductive and can easily generate high-voltage static charges through friction in dry environments. As a result, sensors based on capacitance or electrical signal detection are frequently disturbed. Minor interference causes signal fluctuations, while severe cases may damage internal circuits, triggering unplanned production shutdowns.

Technical Introduction of the Jiwei Dual-Rod Vibrating Level Switch

To address these complex operating conditions, the company introduced the Jiwei dual-rod vibrating level switch. Unlike conventional single-rod vibrating sensors or standard tuning fork designs, the dual-rod structure represents a targeted structural evolution.

The core of the dual-rod design lies in its inner and outer tube configuration. The inner rod functions as the vibration drive element, while the outer rod serves as the sensing element in direct contact with the material. Through precise tuning, the resonance frequencies of the two rods form a highly stable mechanical oscillation system. When material contacts the outer rod, vibration energy is absorbed, causing a noticeable reduction in amplitude and triggering a clear switching signal.

This purely mechanical detection principle eliminates dependence on the electrical properties of the material. Regardless of the level of static charge carried by graphite powder, the vibration frequency and amplitude remain unaffected. This fundamentally resolves one of the most troublesome issues in anode material production: electrostatic interference.

Physical Strategy Against Material Buildup and Adhesion

Material adhesion is the primary reason for level sensor failure in anode material storage. The Jiwei dual-rod vibrating level switch leverages high-frequency mechanical vibration to achieve an effect similar to self-cleaning.

Because the outer rod remains in continuous micro-amplitude vibration, fine powder particles struggle to form a stable adhesion layer. Even during humid seasons, when graphite dust may form a thin coating on the sensor surface, the dual-rod resonance system maintains strong immunity to material buildup. The system responds only to substantial material coverage and remains insensitive to minor surface deposits.

This stability has been verified in actual operation. During testing in the finished product silos at the Suzhou facility, the Jiwei level switch did not experience a single false alarm caused by material adhesion throughout continuous operation cycles. Compared with previously used devices, maintenance frequency was reduced from weekly cleaning to routine inspections conducted only once every six months.

New Requirements at the Sensing Layer Driven by Material Evolution

As the new energy industry continues to pursue higher energy density, anode materials are transitioning from pure graphite to silicon–carbon composites. While silicon–carbon materials significantly improve battery capacity, they exhibit more active physical behavior and require extremely strict control over impurities, especially metallic contamination.

The Jiwei vibrating level switch uses high-grade stainless steel with finely polished contact surfaces, ensuring that no metallic contamination is introduced into the material. At the same time, as silicon–carbon materials are increasingly adopted, bulk density variations become more pronounced. The Jiwei vibrating level switch supports multi-stage sensitivity adjustment, allowing a single device to adapt to materials with different bulk densities. This provides a solid hardware foundation for flexible production.

Accurate sensitivity control also effectively prevents silo overflow. In the anode material industry, overflow not only results in the loss of high-value materials but also creates severe dust pollution and potential safety hazards. Through reliable level feedback, the company achieved closed-loop level control, ensuring continuous and stable production.

From Passive Maintenance to Proactive Monitoring

After implementing the Jiwei solution, the company’s production management approach shifted noticeably. Previously, instrumentation technicians spent much of their time responding to false alarms and manually cleaning sensors, operating in a reactive, firefighting mode. With reliable level signals, the production control system can now perform fully automated material replenishment based on accurate level feedback.

This transformation reduced labor costs and, more importantly, brought a qualitative improvement in production stability. Zero false alarms mean that packaging lines no longer need to stop and restart due to incorrect level signals. As a result, overall equipment effectiveness (OEE) improved significantly.

For new energy manufacturers, intelligent manufacturing does not begin with algorithms, but with every accurate and trustworthy sensor signal. The Jiwei dual-rod vibrating level switch acts as a digital sentinel, delivering clear and reliable material status signals even under extremely harsh operating conditions.

Industry Trend: Precision and Localization of New Energy Equipment

The success of this application also reflects a broader trend in new energy equipment selection: the deep integration of localization and specialization.

In earlier stages, many critical measuring points relied heavily on imported sensors. However, such products often lack flexibility and are not designed for the high-intensity operating conditions common in Chinese new energy factories. As a local manufacturer, Jiwei conducted extensive field research in anode material production environments. Its dual-rod structure directly addresses the limitations of imported products in ultra-fine powder measurement.

As China’s new energy industry expands globally, suppliers like Jiwei—who focus on niche applications and solve problems through fundamental physical principles—are becoming indispensable parts of the industrial ecosystem. Looking ahead, emerging technologies such as solid-state batteries will impose even stricter requirements on material storage conditions, including vacuum, ultra-low temperatures, and higher pressures. Measurement devices based on mature dual-rod resonance platforms will offer stronger technical scalability in these future scenarios.

Conclusion

Although level measurement may appear minor, it is a cornerstone of automated operation in new energy manufacturing. The experience of the Suzhou company demonstrates that when dealing with highly challenging anode materials, returning to fundamental physical principles and selecting instruments with strong anti-interference and anti-buildup capabilities is the most effective way to overcome production bottlenecks.

With its zero false-alarm performance, the Jiwei dual-rod vibrating level switch not only delivers tangible economic benefits but also provides robust sensing support for precision manufacturing in the new energy industry.