Styrofoam Level Switch Replacement: Fork-11 vs E+H

In industries such as packaging, insulation, and home appliance manufacturing, Styrofoam (expanded or extruded polystyrene foam) is a common lightweight material in granular or fragmented form. With ultra-low bulk densities (typically below 10 g/L), irregular particle shapes, and a tendency to generate static and dust, level detection in Styrofoam storage and transfer systems has long posed a challenge.

Foam Material Level Detection: An Industry Pain Point

International brands like Endress+Hauser (E+H) have promoted their Soliphant FTM51 for such applications. However, when it comes to detecting extremely lightweight bulk solids, the FTM51 struggles with sensitivity, has limited temperature tolerance, and comes at a higher cost—prompting many users to seek a high-performance, domestic alternative.

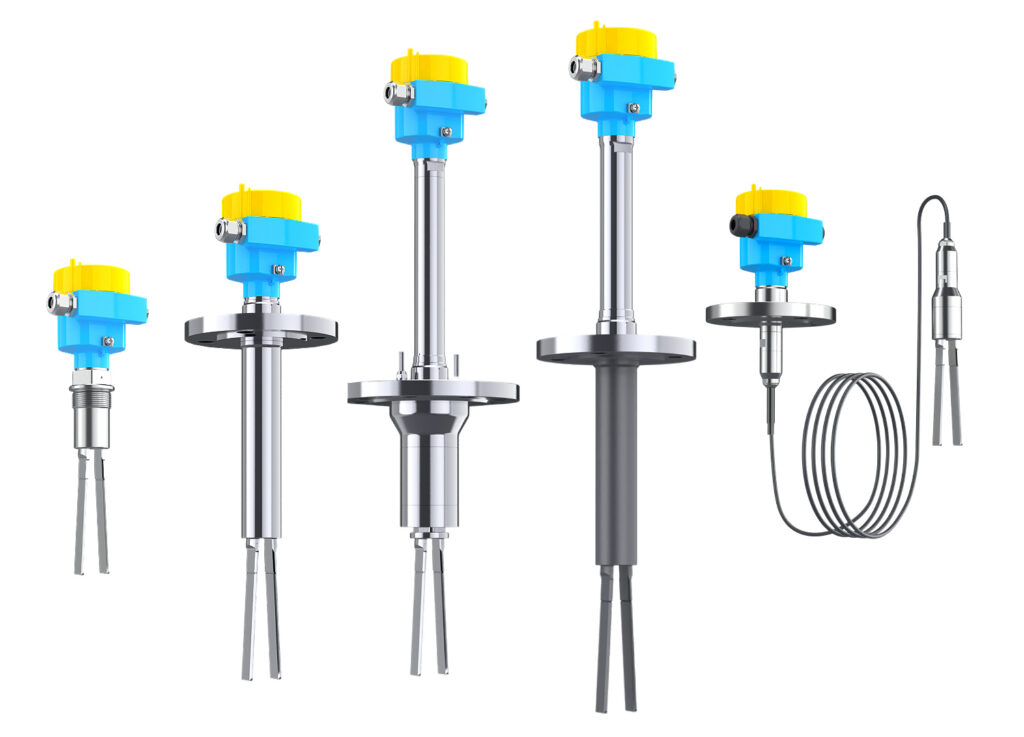

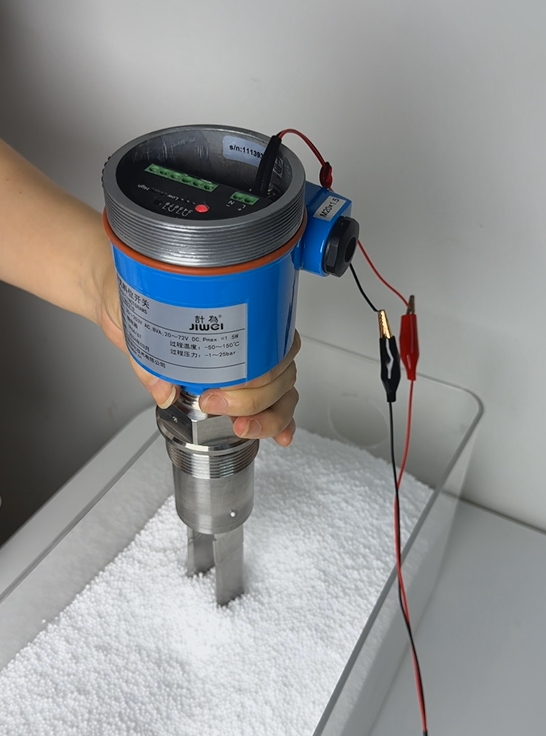

This is where JIWEI Automations’ Fork-11 tuning fork level switch comes in. Designed for low-density solid bulk applications, Fork-11 offers a cost-effective, technically superior replacement to the E+H FTM51 and has proven itself across a wide range of industrial projects.

Project Background

The client, a leading domestic manufacturer of insulation materials, previously used capacitive probes and E+H FTM51 to monitor upper and lower level limits in foam storage silos. However, the system suffered from frequent false alarms, probe fouling, and length limitations (max 4 meters), making it unsuitable for deeper silo installations. The client required a reliable, low-maintenance, and domestically produced solution.

Application Challenges

- Material: Styrofoam (polystyrene foam pellets)

- Bulk density: ~8 g/L

- Silo Structure: Vertical silo, depth 5.2 meters

- Environment: High dust, strong static charge, temperatures up to 90°C

- Monitoring Needs: High and low point detection, high accuracy, no false triggers

Fork-11 Advantages Over E+H Soliphant FTM51

✅ Superior Low-Density Sensitivity

Fork-11 detects materials as light as 8 g/L, surpassing the FTM51’s 10 g/L threshold, making it more reliable for foam, plastic flakes, and light powders.

✅ Extended Insertion Depth

Supports probe lengths up to 6 meters, covering deep silos with ease. FTM51 maxes out at 4 meters, limiting its application in larger tanks.

✅ Self-Cleaning Fork Structure

Minimizes false alarms caused by dust accumulation or static buildup, reducing downtime for maintenance.

✅ Higher Temperature Tolerance

Operates reliably up to 400°C, significantly higher than the 280°C limit of FTM51—ideal for drying, extrusion, or heated storage processes.

✅ Flexible Multi-Point Installation

One model suits various point-level needs. The client used two Fork-11 units for high and low-level alarms with stable, precise operation.

Customer Feedback

The client installed two Fork-11 switches—one for high-level and one for low-level detection. After three months of operation:

“We used to rely on the E+H Soliphant FTM51, but it was unresponsive with lightweight materials and generated false alarms. The Fork-11 has been surprisingly effective—sensitive, durable, and easy to maintain. A true fit for our needs.”

The installation has been stable and maintenance-free, significantly reducing the need for manual inspection.

Performance Comparison

| Feature | JIWEI Fork-11 | E+H Soliphant FTM51 |

|---|---|---|

| Min. Detectable Density | 8 g/L | 10 g/L |

| Max Operating Temperature | 400°C | 280°C |

| Max Insertion Length | 6 meters | 4 meters |

| Self-Cleaning Function | Yes | Yes |

| Mounting Orientation | Any | Any |

| Delivery & Cost | Fast, domestic | Longer lead time, higher price |

Conclusion: The Best Domestic Option for Foam Material Detection

As the only Chinese manufacturer capable of producing tuning fork level switches up to 6 meters, JIWEI Automations delivers world-class reliability with competitive pricing. Trusted by PetroChina, China Aerospace, Tesla, and VEGA, JIWEI continues to expand its footprint across high-demand industries.

The Fork-11 level switch is proven in applications involving Styrofoam, plastic granules, lime, urea, and more—making it an ideal replacement for international brands in point-level detection of solid bulk materials.