Top 5 Benefits of Magnetic Level Gauges: A Complete Guide to Installation, Features, and Maintenance

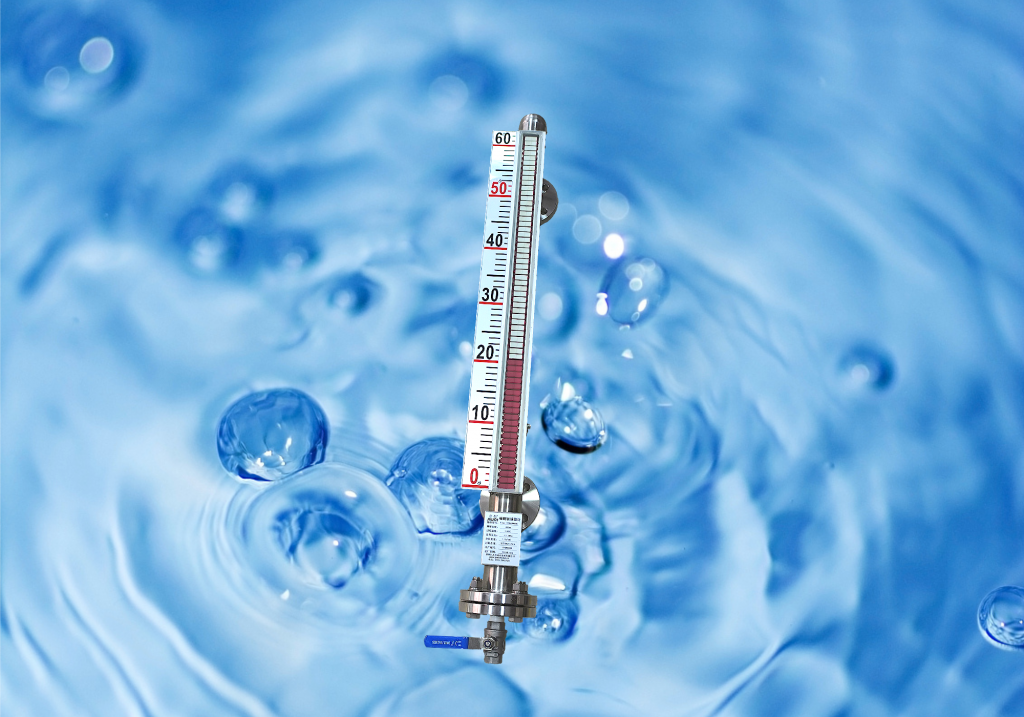

Magnetic Level Gauge: A Complete Overview

The Magnetic Level Gauge is widely recognized for its reliability and ease of use in liquid level measurement across various industries such as chemical, petrochemical, and food processing. It operates on the principles of buoyancy and magnetic coupling, offering a straightforward and robust solution to monitor liquid levels effectively.

Below is an overview of the working principle, structural features, and benefits of Magnetic Level Gauges:

Table: Key Features and Benefits of Magnetic Level Gauges

| Aspect | Details |

|---|---|

| Working Principle | Operates on buoyancy and magnetic coupling; the float moves with the liquid level and flips magnetic flaps to show level. |

| Key Components | Float, magnetic flaps, casing, display window. The float contains magnetic materials and moves in response to liquid level changes. |

| Structural Features | – No mechanical contact (prevents wear and tear)- Color-flip display (easy visual indication)- High-pressure and high-temperature resistance- Leak-proof design- Easy installation with modular design. |

| Application Fields | – Chemical Industry: High-pressure, corrosive liquids- Oil & Gas: Storage tank and pipeline monitoring- Food & Beverage: Hygiene and precision requirements- Water Treatment: Essential for monitoring water levels- Pharmaceutical: Ensures accurate, contamination-free measurements. |

| Installation & Maintenance | – Installation: Install parallel to the container wall for accuracy- Maintenance: Regular cleaning, calibration, and scale prevention. Calibration is important for sustained accuracy, especially in extreme environments. |

| Advantages | – Simple design and operation- No moving parts (reduces wear)- High reliability and durability- Visual level indication with no electronics involved- Ideal for hazardous, corrosive, or extreme environments. |

Working Principle of Magnetic Level Gauge

The Magnetic Level Gauge uses a combination of buoyancy and magnetic coupling to detect and display liquid levels. The float inside the gauge moves with the rise and fall of the liquid level, carrying a magnetic element that flips the external magnetic flaps. These flaps are color-coded (usually red and white), allowing operators to visually read the liquid level by observing the color changes in the display window.

Key Structural Features

- Buoyancy and Magnetic Coupling: The float moves with the liquid level, which in turn triggers the flipping of the external magnetic flaps, providing a direct visual indicator of the liquid level.

- No Mechanical Contact: The float and the magnetic flaps are magnetically coupled, ensuring that there is no mechanical wear and tear, which would otherwise affect the accuracy and lifespan of the gauge.

- Leak-Proof and Durable Design: Magnetic Level Gauges are built to withstand challenging conditions, making them ideal for corrosive, toxic, and high-pressure environments. They are also highly resistant to extreme temperatures.

Applications

Magnetic Level Gauges are particularly suitable for industries that deal with hazardous and high-pressure liquid environments, including:

- Chemical Industry: They are used to monitor liquid levels in reactors, storage tanks, and pipelines where high pressure and corrosive substances are common.

- Oil & Gas Industry: These gauges are perfect for monitoring liquid levels in crude oil and natural gas storage tanks, as well as in pipeline systems where high accuracy and reliability are required.

- Food & Beverage Industry: The gauges meet the strict hygienic requirements and are used to measure liquid levels in vats, tanks, and processing lines.

- Water Treatment: They are used in water and wastewater treatment plants for monitoring liquid levels in storage and treatment tanks.

- Pharmaceutical Industry: Magnetic Level Gauges ensure accurate and contamination-free measurement of liquids, making them ideal for pharmaceutical production.

Installation & Maintenance Tips

For optimal performance, correct installation and regular maintenance are crucial. Here are some key points:

- Installation: Ensure the gauge is installed parallel to the container’s sidewall for accurate readings. Choose the appropriate flange size and sealing materials based on the liquid’s characteristics.

- Maintenance: Keep the display window clean to ensure visibility. If measuring corrosive or contaminated liquids, regular cleaning is essential to prevent buildup. Periodically calibrate the gauge to maintain measurement accuracy.

- Scale Prevention: In some environments, scaling may accumulate on the float or magnetic flaps, which can affect the instrument’s performance. Regular inspection and cleaning can prevent this issue.

Conclusion

The Magnetic Level Gauge is an excellent solution for liquid level measurement, providing simplicity, reliability, and durability across various industries. Its ability to operate without mechanical contact, combined with its visual display and resistance to harsh environments, makes it ideal for applications in chemical, pharmaceutical, and oil & gas industries, among others. By understanding its working principle and key features, companies can make informed decisions on choosing the right level measurement technology for their processes, ensuring greater efficiency and accuracy.