Understanding Level Migration in Level Transmitters

In industrial automation, accurately measuring material levels inside tanks and vessels is crucial. One often overlooked but vital concept in level measurement is level migration. Simply put, level migration refers to adjusting the measurement range of a level transmitter so that it accurately reflects the actual level in the vessel or pipeline.

What Is Level Migration?

Level migration involves calibrating or shifting the level transmitter’s measurement starting point. This adjustment is necessary when the transmitter’s installation position, medium properties, or isolation fluids cause discrepancies between the measured value and the true level.

For example, if a level transmitter is installed in an unconventional position, or if the medium being measured is unusual or isolated by a liquid column, the raw output may not match the real level. Level migration corrects this mismatch to provide precise readings.

Types of Level Migration

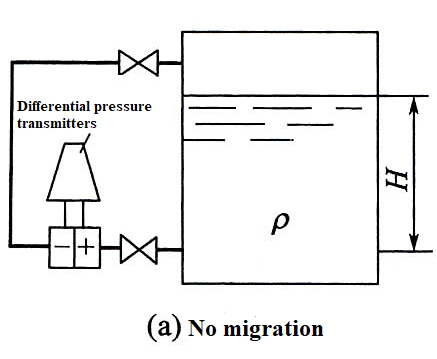

No Migration: The measurement starts from zero. This is the standard, ideal condition where the transmitter’s zero corresponds exactly to the lowest level.

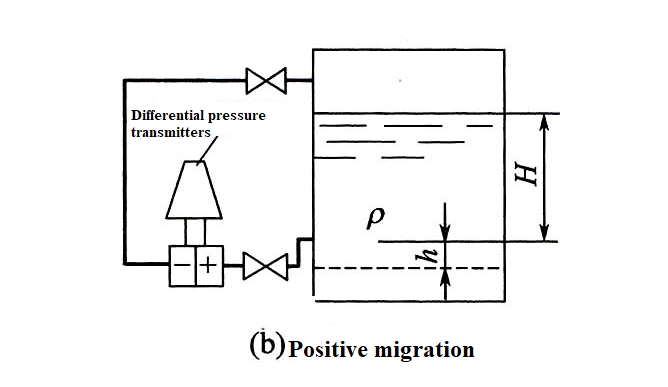

Positive Migration: The measurement starting point is above zero. For instance, when the transmitter detects pressure even at the lowest level, the zero point is shifted upward.

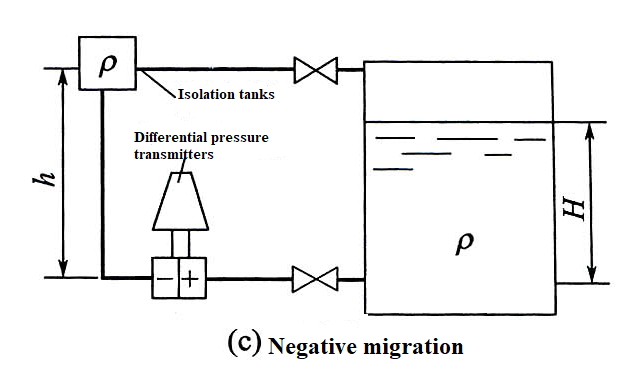

Negative Migration: The measurement starting point is below zero. This occurs when the transmitter registers negative pressure at the lowest level, shifting the zero point downward.

Level Migration vs. Zero Adjustment

It is important to distinguish level migration from zero adjustment:

- Zero Adjustment: When the transmitter has zero differential pressure (Δp = 0), the output is set to zero. This is done when the transmitter is not under any pressure.

- Level Migration: When the transmitter is under pressure (Δp ≠ 0), the output is calibrated to zero at the actual lowest measurable level, even though there is a pressure offset.

How Is Migration Quantified?

Level migration is typically expressed as a pressure value or a percentage of the full measurement range.

Mathematically, if we denote:

- yminy_{min} as the transmitter’s output lower limit,

- xminx_{min} as the actual lower limit of the measurement range,

then:

- If xmin=0x_{min} = 0, this is considered zero adjustment.

- If xmin≠0x_{min} \neq 0, this is level migration.

Migration can be further classified by direction:

- Positive Migration: Measurement start point is shifted above the reference zero.

- Negative Migration: Measurement start point is shifted below the reference zero.

When Is Level Migration Necessary?

In practical field applications, migration adjustment is often required under several typical conditions:

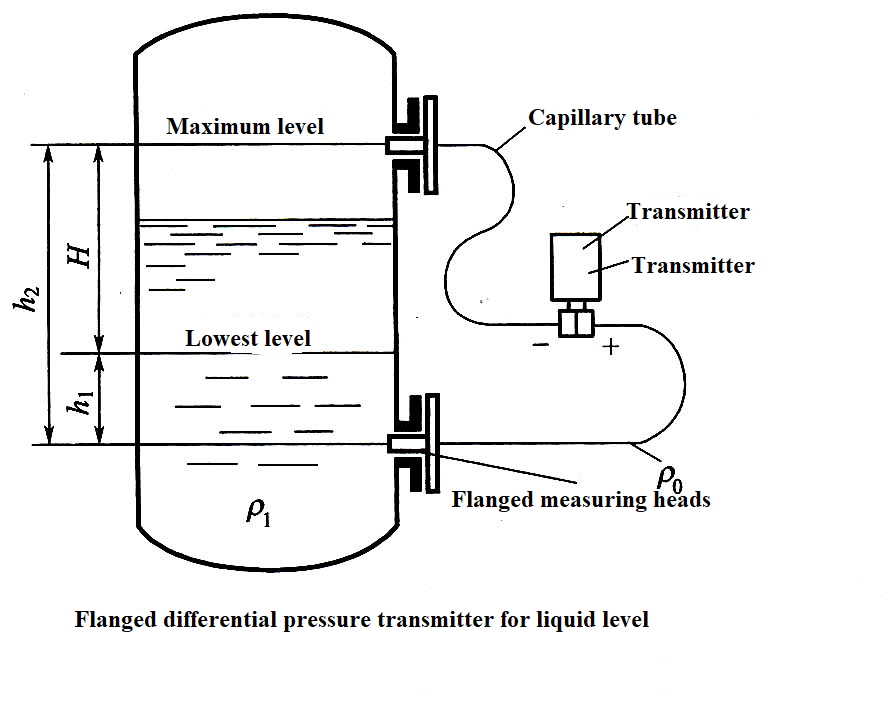

1. Double-Flange Level Transmitters

- Application: Used for sealed vessels containing high-viscosity, crystallizing, or corrosive media, such as reactors in chemical plants.

- Reason for Migration: Different installation heights of the upper and lower flanges cause pressure differences. Without migration correction, the level readings will be inaccurate.

2. Single-Flange Level Transmitters with Capillary Tubes

- Application: Suitable for open tanks or sealed vessels.

- Reason for Migration: If the transmitter is mounted above or below the lowest level, pressure readings can deviate, requiring migration to align output with actual levels.

3. Differential Pressure Transmitters with Isolation Tanks

- Application: Ideal for highly corrosive or viscous media such as sulfuric acid or heavy oil.

- Reason for Migration: The isolation fluid column adds pressure, affecting measurements. Migration compensates for this to ensure accuracy.

Field Calibration Tips: Quick Setup for Double-Flange Transmitters

To calibrate level migration on double-flange transmitters, follow these steps:

- Close valves to expose both upper and lower flanges to atmospheric pressure (vent to air).

- At this point, the transmitter’s process variable (PV) reading corresponds to the lower measurement limit (migration zero point).

- Calculate the upper measurement limit based on the actual liquid height and input the full range accordingly.

The Essence of Level Migration

Level migration ensures the transmitter’s output signal (commonly 4–20 mA) corresponds accurately with the actual level.

- When the lowest level corresponds to 4 mA output, there is no migration.

- If the lowest level output is above 4 mA (e.g., 8 mA), this indicates positive migration.

- If the lowest level output is below 4 mA (e.g., 0 mA), this indicates negative migration.

Why Important?

Accurate level measurement is foundational for safe and efficient industrial operations. Misreading levels due to improper transmitter installation or uncorrected pressure offsets can lead to:

- Safety hazards from overfilling or dry-running equipment.

- Production downtime caused by inaccurate inventory management.

- Damage to equipment from corrosive or crystallizing media not properly monitored.

By applying level migration calibration, engineers ensure that the level transmitter readings truly represent the conditions inside the vessel or tank.

Conclusion

Level migration is a critical calibration step that aligns level transmitter outputs with actual process conditions. Understanding the types of migration and when to apply them ensures reliable and accurate level measurement across various industrial scenarios. Whether dealing with complex installations like double-flange setups or compensating for isolation fluid pressures, mastering level migration calibration boosts process safety and operational efficiency.

level , level transmitter calibration, double-flange level transmitter, differential pressure transmitter, level measurement accuracy, industrial level measurement, migration vs zero adjustment