Why 80 GHz Radar Level Meters Deserve Your Attention in Chemical Applications

In today’s rapidly evolving level measurement landscape, 80 GHz radar level meters have emerged as the preferred technology across industries such as chemical processing, pharmaceuticals, and environmental protection. With numerous options like differential pressure, guided-wave radar, nuclear, and through-air radar, making the right choice can be challenging. But as 80 GHz high-frequency radar tech matures, several long-standing issues are being solved.

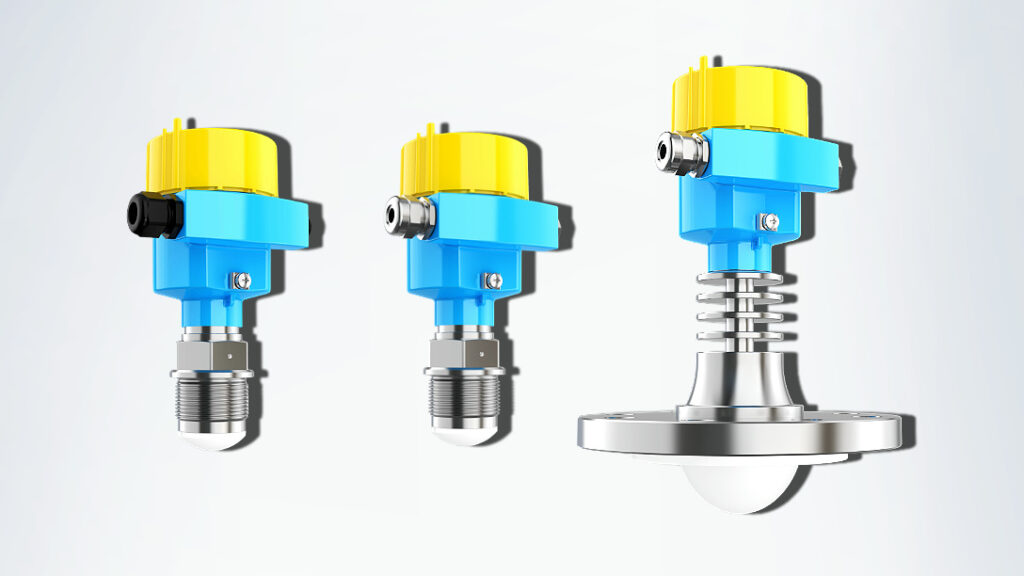

Jiwei’s JWrada® 80 GHz radar level meters exemplify this new generation of innovation. This article presents three key reasons—each tied to real-world chemical plant conditions—why these radar sensors are a top recommendation for applications demanding high safety, reliable performance in complex environments, and non-contact measurement.

1. Non-Contact Measurement Through Glass or Plastic

Many reactors and storage tanks in chemical plants feature sight windows for visual monitoring of liquid level or mixing. Installing measurement instruments typically required costly tank modifications—drilling holes, adding flanges, risking contamination and shutdown.

JWrada® 80 GHz radar level meters offer fully non-contact measurement through non-conductive tank walls such as glass or sturdy plastic. This simplifies installation, enhances operator safety, reduces maintenance needs, and minimizes modification costs.

Built on high-frequency 80 GHz waves and a tight beam angle (as small as 3°), JWrada® penetrates window materials with precision, even when installation angles are as low as 5–10 degrees. Narrow beam focus avoids reflections from window edges, delivering stable, clear radar echoes without tweaking tank geometry.

2. Accurate Measurement of Low-Dielectric Liquids and Challenging Media

Chemical fluids like solvents, oils, and diluted acids often have low dielectric constants, leading to weak radiation returns and poor radar signal quality. Traditional radar systems can struggle—or fail entirely—to detect the liquid level.

With its 120 dB dynamic range, JWrada® excels where 90 dB devices cannot. This enhanced sensitivity enables consistent measurement of liquids with dielectric constants as low as 1.4. Think about challenging media like palm oil, strong solvents, or benzene—the JWrada® handles them reliably.

Its capabilities make it ideal for environments where tank contents change frequently. One device can manage various media without recalibration or configuration changes, simplifying operations and ensuring accuracy.

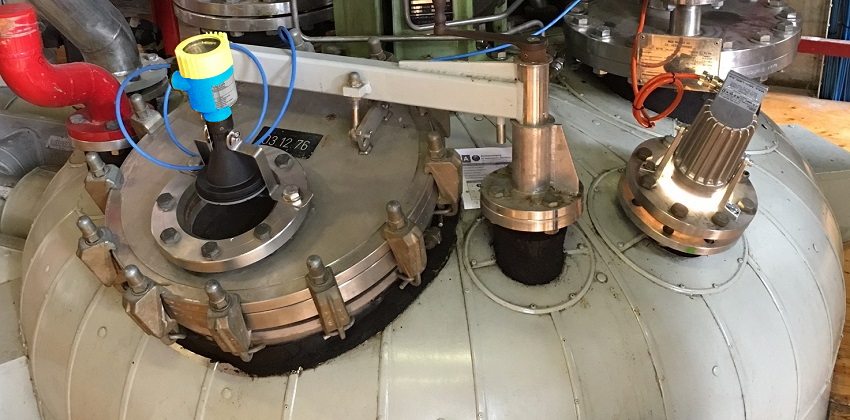

3. Stable Measurement Installed on Isolation Valves and Nozzles

In hazardous or corrosive environments, isolation valves or long nozzles are often used to separate sensors from the process fluid—enabling maintenance without draining tanks or halting production.

Conventional 26 GHz radars, with their broader beams, often suffer from echo interference within valves or nozzles. JWrada® addresses this with its ultra-narrow beam and focused signal path, navigating structural obstacles to provide clean, accurate level data.

In real-world applications, JWrada® has performed flawlessly on:

- 3″ and 4″ ball valves

- Long nozzles up to 1.5 m in length

With no echo noise from valve or pipe walls, it is perfectly suited for complex vessel designs and critical processes.

Summary: Why JWrada® Stands Out

| Key Benefits | Impact in Chemical Plants |

|---|---|

| Non-contact measurement | Safe installation through sight windows—no need for tank modifications or direct process contact |

| 120 dB dynamic range | Reliable measurements of low-DK liquids, foams, and challenging media |

| 3° narrow beam | Works on valves, nozzles, and tight spaces without signal distortion |

| Intrinsically safe & interference-resistant | Ideal for hazardous zones, moisture-prone areas, and electromagnetic noise environments |

JWrada® isn’t just suitable for standard tanks—it thrives in environments where safety, flexibility, and reliability are mandatory.

Conclusion

80 GHz radar level meters like the JWrada® series are revolutionizing liquid level measurement in chemical plants. They deliver unprecedented adaptability—whether installed through windowed tanks, across valve lines, or in difficult-to-access spots. With enhanced dynamic range and narrow beam technology, JWrada® reliably handles glass, foam, sludge, low-dielectric fluids, and complex geometries without compromising accuracy or safety.

If your process demands precision, flexibility, and maintenance efficiency, the new generation of 80 GHz radar with 120 dB dynamic range offers a smarter solution than ever.