Hidden Powers of Radar Level Transmitters: 4 Key Advantages of 80 GHz Technology

Radar level transmitters have become essential instruments in industries like petrochemicals, metallurgy, food processing, and water treatment. Their resilience to interference, maintenance-free operation, and stable performance under harsh conditions such as condensation, vapor, and temperature fluctuations make them a trusted choice. However, radar level transmitters offer more capabilities than most realize. This article explores four hidden strengths of modern 80 GHz radar level transmitters and why these features are critical for advanced level measurement.

1. True Non-Contact Measurement Through Glass and Plastic

In environments demanding high corrosion resistance or involving hazardous chemicals, it’s increasingly common to install radar sensors outside glass windows or plastic tank walls. This approach enables genuine non-contact level measurement, preventing direct exposure to process liquids, which reduces leakage risk, lowers maintenance frequency, and extends sensor lifespan.

Beyond just glass or plastic, modern 80 GHz radar waves can penetrate various non-conductive materials, including advanced composite resins, engineering plastics, and even some refractory brick structures. This capability expands installation possibilities and ensures reliable measurement without tank modifications.

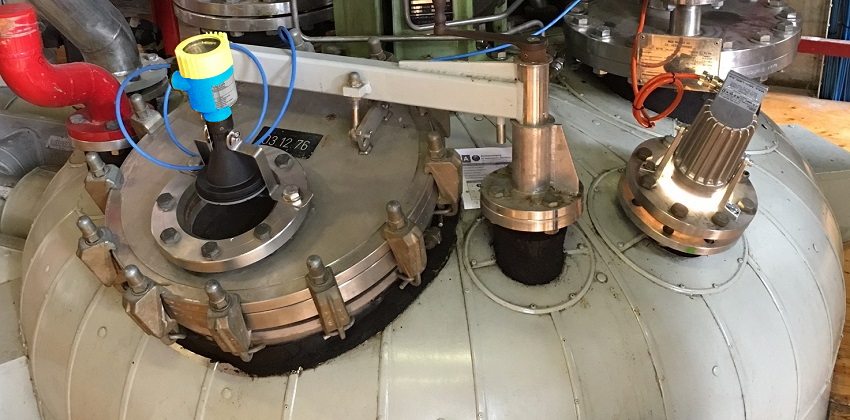

2. Seamless Integration with Isolation Valves for Maintenance Without Downtime

For measuring highly corrosive, toxic, or pressurized liquids, users often install isolation valves ahead of the radar sensor. This setup allows safe sensor maintenance or replacement simply by closing the valve, avoiding costly tank emptying or production halts.

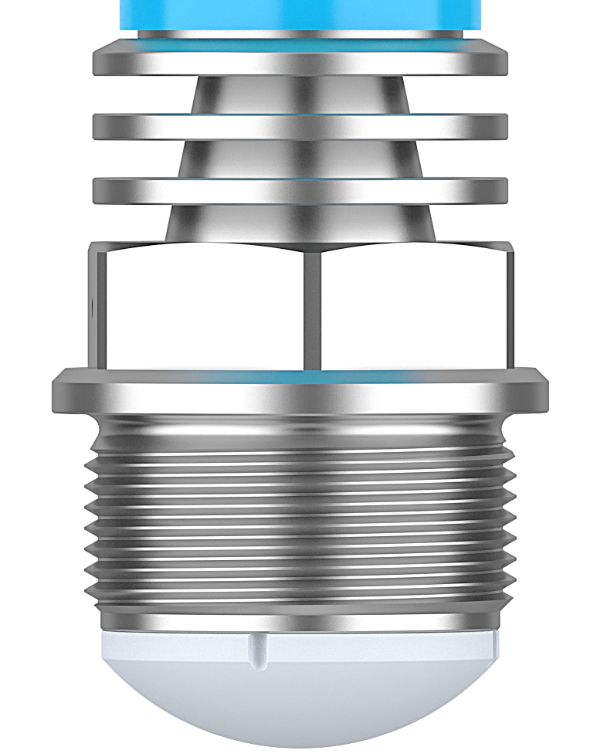

Traditional 26 GHz radars typically emit wider beams that reflect within valve bodies, causing signal interference and unstable measurements. In contrast, 80 GHz radar sensors have an ultra-narrow beam—sometimes as narrow as 3 degrees—that concentrates signals to bypass valve structures, maintaining clean and reliable echoes.

Field validations confirm these sensors perform stably on DN80 (3-inch) and DN100 (4-inch) ball valves, and even some gate valves, meeting demanding industrial requirements.

3. Flexible Installation Even in Confined or Complex Spaces

Historically, radar level sensors were recommended to be installed at a distance from tank walls to avoid reflection and signal disturbance, especially in spherical or dome-shaped tanks. However, actual plant layouts often limit ideal placement due to tight piping and space constraints.

Modern 80 GHz radar transmitters feature narrow beams and enhanced interference rejection, enabling accurate measurement even when mounted close to tank walls or at non-central locations. This flexibility simplifies field installations, retrofits, and reduces costly structural changes.

4. Reliable Measurement of Low Dielectric Constant Liquids

Measuring liquids with low dielectric constants (DK) like oils, organic solvents, or foams has traditionally been challenging because their weak radar reflection yields faint signals.

80 GHz radar transmitters with a dynamic range up to 120 dB provide about 1,000 times greater sensitivity than typical 90 dB devices. This boost allows detection of weak echo signals from low DK liquids (as low as 1.5), dramatically improving measurement reliability across chemical processing, food production, and environmental industries.

Why Dynamic Range Matters

Dynamic range refers to the ratio between the strongest and weakest echo signals a radar sensor can detect, measured in decibels (dB). A wider dynamic range means the sensor can “hear” faint echoes alongside strong ones, crucial for accuracy in challenging conditions such as foam, vapor, or dirty antenna surfaces.

The leap from 90 dB to 120 dB dynamic range represents a thousand-fold improvement in sensitivity, opening new frontiers in radar measurement performance.

Conclusion: Expanding the Possibilities of Radar Level Measurement

The advancements in 80 GHz radar transmitters redefine how and where level measurement can be done. From non-contact measurements through tough materials, safe maintenance with isolation valves, flexible installation in cramped spaces, to reliable readings of difficult low-DK liquids—the technology significantly broadens application scope.

If you face complex level measurement challenges, consider how next-generation 80 GHz radar transmitters can provide safer, more flexible, and more reliable solutions tailored to your demanding industrial processes.