Anode Material Level Measurement Solution | Jiwei Dual-Rod Vibrating Level Switch for Graphite and Silicon-Carbon Silos

The Undervalued Role of Level Measurement in New Energy Manufacturing

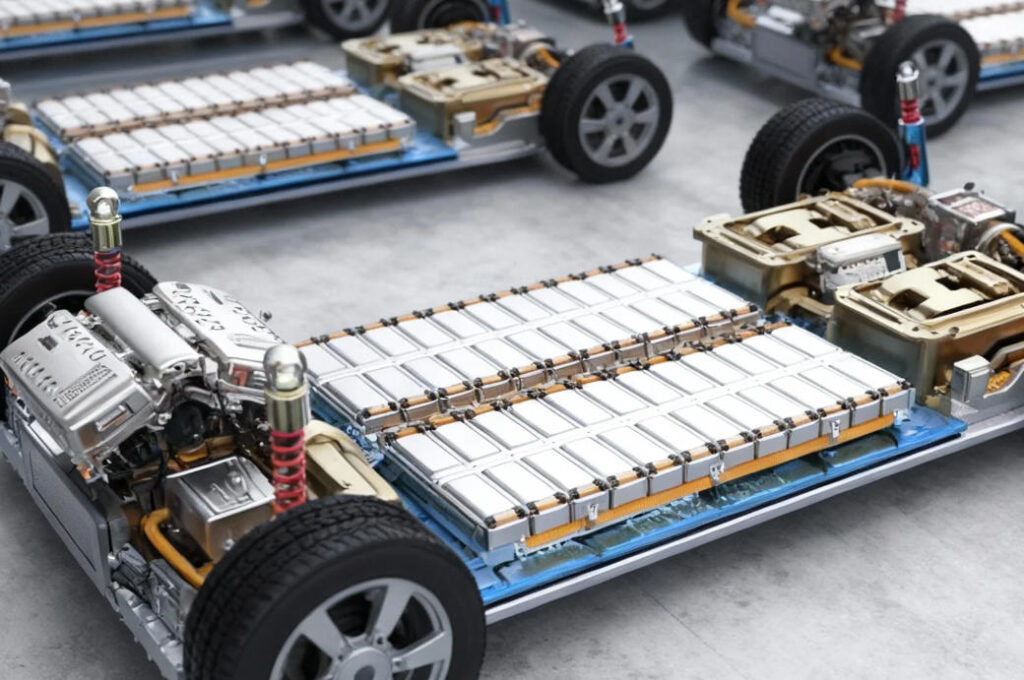

Within the new energy industry supply chain, the manufacturing of lithium battery materials is rapidly moving toward high levels of automation and continuous processing. Compared to battery cell design, chemical formulations, and core processing equipment, level measurement is often regarded as a mature, standardized component that is frequently simplified during the design phase.

However, in actual production—particularly in the storage and transport of anode materials—if the level signal becomes distorted, the impact extends far beyond a mere inaccurate alarm. It directly disrupts the feeding rhythm, triggers emergency shutdowns, and can even cause silo overflows or material shortages. This makes it a hidden bottleneck that constrains the stable operation of the entire production line.

Typical Measurement Challenges for Lithium Battery Anode Materials

A new energy technology company in Jiangxi Province has long faced issues with unstable level measurements during its anode material production. The stored materials consist mainly of graphite and silicon-carbon, which exhibit the following characteristics:

- Fine powder with a high specific surface area that easily adheres to sensor surfaces.

- Tendency to generate significant static electricity in dry environments, interfering with electronic signals.

- Material fluidity that fluctuates based on humidity and process speed, leading to unstable material levels.

Under these conditions, conventional level switches frequently experienced false alarms, delayed responses, or total failure. Sometimes the system would report a full silo when it was not, and other times it failed to output a signal as it approached empty, severely compromising production continuity and safety.

Why Traditional Level Solutions Fail

Through onsite investigations, the company discovered that the problem was not a simple equipment defect, but rather a mismatch between the measurement principle and the material properties.

In high-dust and high-static environments, many traditional point level switches are susceptible to material buildup and electrostatic interference, which cause the detection threshold to drift. Over time, false alarms evolved from occasional incidents to a constant problem. Eventually, the facility had to rely on frequent manual intervention, which defeated the purpose of the original automated design.

Technical Logic of the Jiwei Dual-Rod Vibrating Level Switch

To address this pain point, the company introduced the Jiwei dual-rod design vibrating level switch at critical silo positions. Unlike traditional single-rod or fork structures, this product utilizes a symmetrical dual-rod resonance structure that judges material contact through stable changes in the resonant state.

This structure provides distinct advantages for anode material applications:

- Effective interference rejection: The dual-rod resonance effectively cancels out the interference caused by dust adhesion. Even if there is a certain amount of material buildup on the rod surface, it will not trigger a false signal.

- Independence from electrical properties: The detection result does not depend on changes in the material’s dielectric constant. This provides excellent adaptability to different ratios of graphite and silicon-carbon mixtures.

- Patented innovation: As a pioneer in dual-rod design in China, the product holds three invention patents specifically for its structural reliability.

Stable Performance in Complex Environments

In the field, the Jiwei vibrating level switches were installed at key high and low points of the raw material silos and integrated with the supervisory control system. The equipment can operate stably for long periods in humid and dusty environments without being affected by ambient static or material fluctuations.

Following implementation, the company tracked the operational data closely. The results showed that the false alarm rate dropped to zero. Previous issues such as silo overflows and empty-bin incidents were completely eliminated, significantly improving the operational status of the storage and transport sections.

Value for Production Continuity and System Stability

Once the level signals stabilized, the overall synergy of the production system improved. Upstream feeding is no longer interrupted by false full-bin reports, and downstream processes avoid the risk of shutdowns caused by material shortages. For new energy manufacturers, this improvement manifests not only in efficiency but also in a direct reduction of operational risks and maintenance costs.

From a systemic perspective, reliable level detection provides a trustworthy foundation for subsequent data analysis, rhythm optimization, and further intelligent upgrades.

Strategic Thinking for the Future of New Energy Manufacturing

As the new energy industry moves toward manufacturing characterized by high consistency and high reliability, basic measurement equipment is shifting from being just functional to being stable and adaptable to complex conditions. In this context, level measurement is no longer a secondary accessory but a vital node in the smart manufacturing architecture.

The application of Jiwei vibrating level switches in this project demonstrates that a truly suitable measurement solution for the new energy industry must stem from the essence of material properties and working conditions. The focus should be on core reliability rather than a simple accumulation of parameters.

Conclusion

The practice at the Jiangxi plant proves that choosing the right measurement principle is more important than frequently replacing equipment. By introducing a vibrating level switch with a more logical structure and stronger anti-interference capabilities, the company successfully solved a long-standing measurement bottleneck, ensuring the continuous and stable production of anode materials.

Would you like me to generate a technical comparison table between the dual-rod resonance principle and traditional point level sensors to further clarify these advantages?