Reliable Tuning Fork Level Switch Solutions for Leachate in Waste-to-Energy Projects

In waste-to-energy and solid waste resource utilization projects, the collection, transportation, and treatment of leachate are unavoidable critical processes. Compared with ordinary industrial liquids, leachate has a complex composition and harsh operating conditions, making level measurement one of the long-standing challenges in on-site automation systems. To address this, tuning fork level switches are often used for reliable monitoring. If level control fails, it can lead to frequent start-stop cycles of equipment at best, or leachate overflow at worst, posing environmental and safety risks.

During the operation of a waste-to-energy project, a certain energy and environmental protection company experienced unstable leachate level measurement, repeatedly encountering false alarms and equipment interlock failures. As a result, the project team re-evaluated the level detection solution and ultimately introduced tuning fork level switches at critical measuring points, resolving the long-standing operational difficulties on site.

Project Background: Characteristics of Leachate in Waste-to-Energy Projects

This project represents a typical waste-to-energy engineering case. After garbage is stored, turned, and compressed in the pits, leachate is continuously produced. This liquid is not from a single source but a mixture of multiple process liquids, including naturally exuded liquid from waste, liquid generated from fermentation reactions, and wastewater produced during pre- and post-incineration processes.

During long-term operation, the site observed the following prominent characteristics of leachate:

- High organic content and strong corrosivity, requiring high resistance in metals and sealing structures;

- Relatively high liquid temperature, especially in summer or under high-load operation, with significant temperature fluctuations;

- Abundant and stable surface foam, with thickness varying with process conditions and not easily dissipating naturally;

- Presence of suspended solids and impurities, prone to adhesion on sensor surfaces.

These characteristics together indicate that leachate level measurement is unsuitable for detection methods with complex structures or those sensitive to the medium.

Practical Issues with the Original Level Measurement Solution

Initially, the site used float level switches and electrode level switches to control leachate levels. Over time, problems gradually emerged:

- Thick foam caused floats to actuate prematurely, triggering high-level alarms before the liquid reached the set point, affecting system judgment.

- The corrosive nature of leachate damaged electrode-based products, reducing signal stability and increasing maintenance frequency.

- High temperature and suspended solids caused some mechanical parts to stick or respond slowly, increasing operational uncertainty and maintenance burden.

After multiple maintenance attempts failed to solve the issues, the project team decided to adopt a level detection method better suited to the harsh leachate conditions.

Selection Approach: Reassessing Leachate Level Measurement Requirements

The team focused on long-term stability in complex media, rather than only measurement accuracy. Leachate contains foam, suspended solids, and corrosive components, and is generally at elevated temperatures. This requires robust structural reliability, material resistance, and long-term operational stability in level switches.

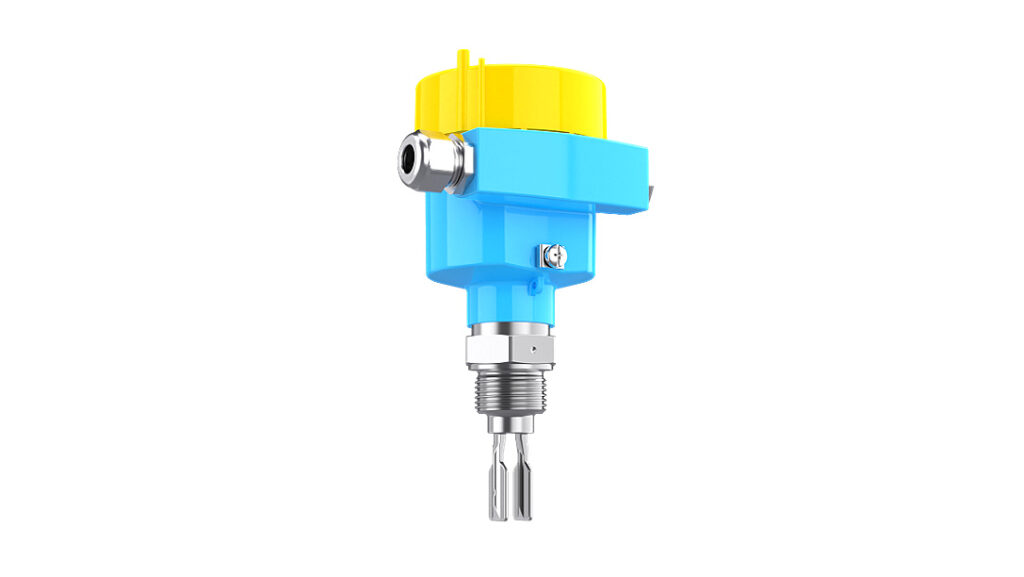

Tuning fork level switches were chosen due to their simple structure, clear working principle, and lack of moving parts.

- They detect liquid presence by changes in vibration status, without relying on buoyancy or medium conductivity.

- They are insensitive to density fluctuations and surface foam, matching leachate’s large level variations and stable foam.

- Their vibration-based operation mitigates the impact of debris adhesion, enabling long-term stable operation in complex media.

Material Configuration

The project team evaluated common domestic configurations. Many products still use carbon steel or 304 stainless steel, which may work under normal conditions but are prone to corrosion, reduced strength, or seal failure in leachate environments, affecting service life and reliability.

Jiwei Tuning Fork Level Switch:

- Standard 316L stainless steel, enhancing corrosion resistance and industrial field adaptability.

- Optional anti-corrosion coatings for high-chloride or high-organic-acid media.

- For more corrosive or complex applications, Hastelloy® C-22 is available for industrial-grade long-term operation.

Technical Measures for Leachate Conditions

- Corrosion Resistance: Fork body and connection parts made of 316L stainless steel with reliable sealing. Anti-corrosion coatings or Hastelloy can be selected for harsher media.

- High-Temperature Adaptability: Designed for up to 400 ℃ to maintain stable vibration and reliable output.

- Foam Interference Resistance: Detects liquid contact via vibration frequency and amplitude, avoiding false alarms from thick, stable foam.

- Optimized Sensitivity: Alarms trigger only when fork tines reach the actuation point, avoiding false alarms from suspended solids, adhesion, or particle contact.

On-Site Application and Operational Effect

Installed at critical points in the leachate regulation tank, the switches monitored real-time liquid levels. Leachate inflow caused large fluctuations, thick foam, and suspended solids, demanding highly stable measurements.

- Level signals remained stable; false alarms were significantly reduced.

- Operators no longer needed frequent manual verification.

- Equipment operated long-term without degradation or component wear.

- Maintenance and cleaning workload were reduced, saving time and cost.

Case Summary: Reliability in Complex Conditions

Leachate level measurement tests material selection, structural design, sensor principle, and field adaptability. Harsh conditions demand:

- High corrosion resistance to prevent surface damage or seal failure;

- Robust structure against high temperature and foam to prevent drift or false alarms;

- Optimized sensitivity to avoid false activation from solids or adhesion.

This project demonstrates that tuning fork level switches optimized for operating conditions provide stable, reliable level signals, reduce maintenance, and minimize manual intervention. Accurate, stable level data supports regulation tanks and downstream equipment, preventing overflow or unplanned shutdowns, achieving a safe operational closed-loop.

For waste-to-energy plants and environmental energy enterprises, selecting level switches compatible with leachate ensures overall system reliability and safety compliance. Materials, structure, and sensor characteristics must match field conditions to achieve long-term stability, low maintenance, and reliable operation.