Hydraulic Oil Tanks: Choosing the Best Radar Level Sensor

In hydraulic oil tanks, oil serves as the lifeblood, transmitting power and providing lubrication. The oil circulates in a closed system, but over time, it is gradually lost through lubrication points and leakages in the power equipment. To ensure the smooth functioning of power equipment, it’s crucial to monitor the oil level in every hydraulic oil reservoir tank and replenish it when necessary. One of the most accurate and reliable ways to achieve this is through radar level measurement.

The Role of Radar in Hydraulic Oil Tank Monitoring

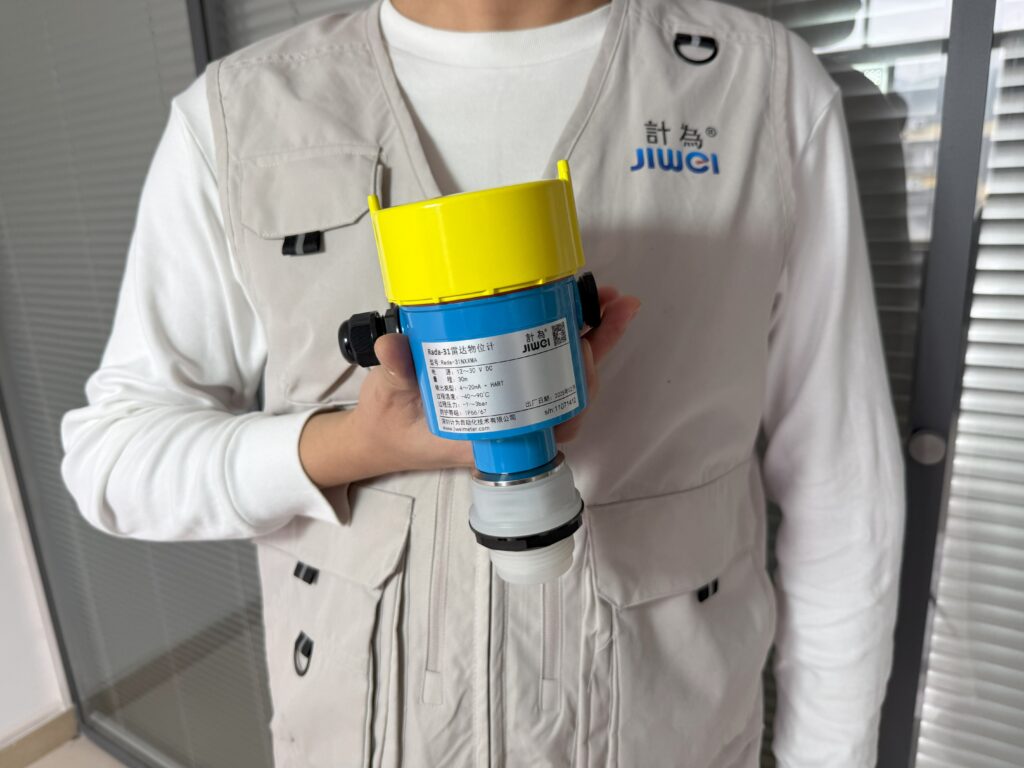

Radar level sensors are a non-contact technology that utilizes microwave signals to measure the distance between the sensor and the surface of the hydraulic oil. These microwave signals are emitted by the sensor and reflected off the surface of the oil, allowing the system to calculate the oil level in real time. This level of precision ensures that the hydraulic oil tank’s level is continuously monitored, preventing issues such as low oil levels that can negatively impact system performance.

Why Choose Radar Level Sensors for Hydraulic Oil Tanks?

- Accuracy in Challenging Conditions

One of the major advantages of radar level sensors is their ability to deliver high accuracy in complex and harsh environments. Traditional level measurement methods, like float switches or ultrasonic sensors, can be affected by factors such as temperature fluctuations, pressure changes, and the properties of the liquid being measured. Radar sensors, on the other hand, are not influenced by these variables. This makes them an excellent choice for hydraulic oil tanks, where conditions can vary significantly. - Non-Contact Measurement

Unlike other level sensors that rely on physical contact with the liquid, radar sensors offer a non-contact solution. This minimizes the risk of wear and tear on the sensor, ensuring a longer lifespan and reducing the need for maintenance. Since radar sensors don’t come into direct contact with the hydraulic oil, they are less likely to become clogged or damaged by debris or contamination in the oil. - High Reliability in a Variety of Liquids

Hydraulic oils come in many different types, each with unique characteristics like viscosity, density, and temperature sensitivity. Radar level sensors can accurately measure the level of hydraulic oil, regardless of its specific properties. Whether the oil is thick or thin, cold or hot, radar sensors maintain their accuracy and reliability, ensuring that the oil level is monitored consistently. - Continuous Monitoring for Optimal Performance

Radar level sensors provide real-time, continuous monitoring of the hydraulic oil level in the tank. This ensures that operators are always informed of the oil’s status, which is crucial for timely replenishment. By maintaining the oil level within an optimal range, the radar sensor helps prevent system malfunctions, overfilling, or underfilling, which can lead to equipment failure and downtime. - Versatility and Easy Integration

Radar sensors are versatile and can be integrated into a wide range of hydraulic systems. They can be used in both small and large tanks, and their installation is typically straightforward. Since radar sensors offer both point-level and continuous measurement capabilities, they can be tailored to meet specific needs in different industrial applications.

The Importance of Reliable Oil Level Monitoring

Hydraulic systems are crucial for the operation of heavy machinery, like industrial equipment and construction vehicles. Maintaining the correct hydraulic oil level is essential to avoid failures, which could lead to costly repairs. Low oil levels can cause overheating and component wear, while overfilling can lead to spillage, contamination, and pressure issues.

Radar level sensors offer an accurate, non-invasive solution to monitor oil levels in real-time. Unlike traditional sensors, they are more reliable and less prone to wear, even in tough environments. By maintaining optimal oil levels, radar sensors reduce system failures, downtime, and maintenance costs. This ultimately enhances equipment performance, extends lifespan, and ensures smooth operation.

Conclusion

Radar level sensors provide a reliable, accurate, and non-invasive solution for monitoring hydraulic oil levels in hydraulic oil tanks. Unlike traditional mechanical or float-based sensors, radar technology offers continuous, real-time measurement without being affected by temperature fluctuations, pressure changes, or oil viscosity variations. Their high precision and ability to function in tough industrial environments make them an essential tool for ensuring the smooth operation of hydraulic systems.

With radar technology, businesses can maintain optimal oil levels, reduce downtime, and avoid expensive repairs, ultimately enhancing the performance, efficiency, and longevity of their hydraulic equipment while improving overall operational safety.