Radar Level Measurement for Bulk Powder Vehicles: Enhancing Safety and Automation in Loading

Radar Level Measurement in Bulk Powder Vehicle Loading: Engineering Application and Safety Advantages

In industries such as cement, building materials, power, and mineral processing, fine particulate products like cement, fly ash, limestone powder, and slag powder are commonly transported using tank-type bulk vehicles. The loading process is not only frequent but also requires high standards for environmental protection, safety, and operational efficiency, making it a critical step in the bulk powder production chain. Radar Level Measurement

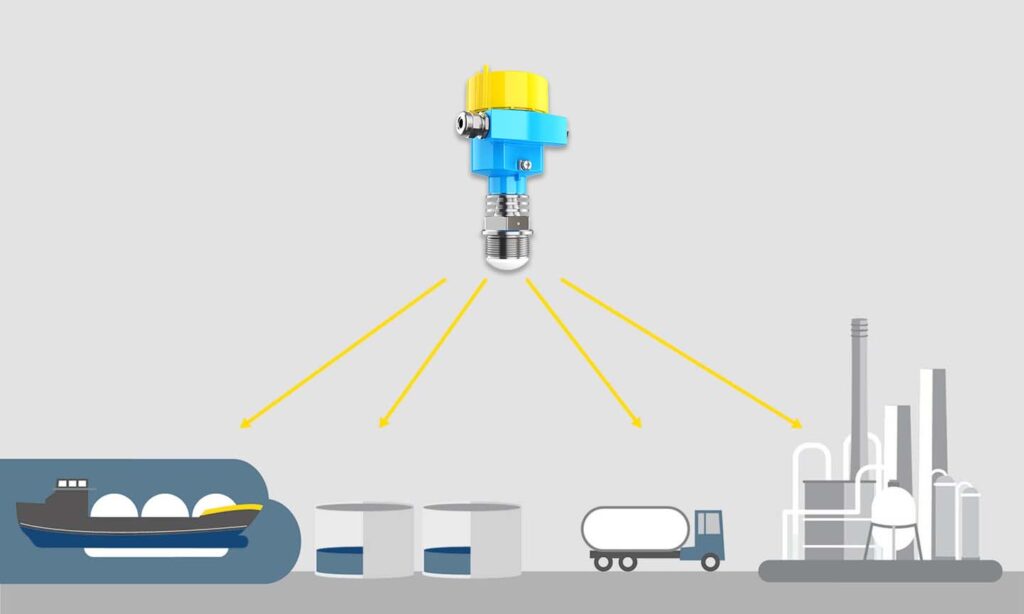

With increasingly stringent environmental regulations, traditional open loading methods are being phased out, while enclosed, dust-free, automated loading systems have become the industry standard. In these systems, radar level sensors are widely applied to monitor solid material levels in specialized vehicles, gradually becoming a key measurement method for ensuring loading safety.

1. Application Scenario: Dynamic Level Measurement at the Filling Port, Not Traditional Inventory

Many users typically associate radar level sensors with inventory measurement in large silos or storage tanks. However, in bulk powder vehicle applications, both measurement logic and installation differ significantly.

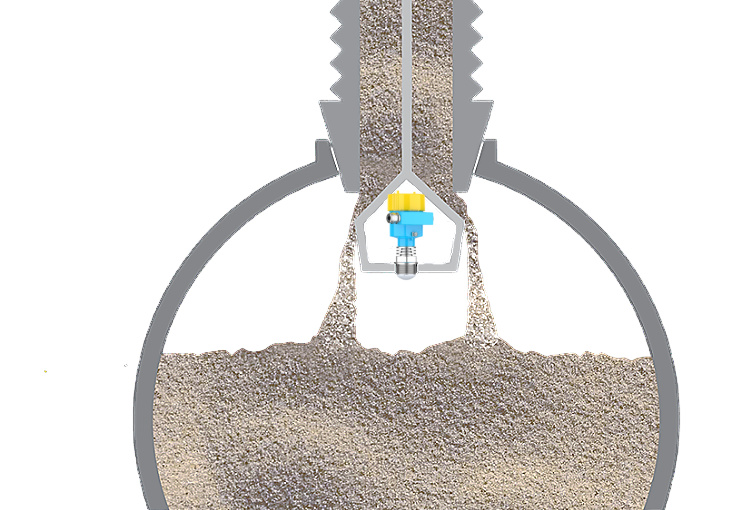

As shown, the radar level sensor is not mounted at the top of the vehicle tank but installed inside an enclosed cavity beneath the filling port, with its measurement direction pointing vertically toward the forming solid material heap inside the tank. This setup indicates that the application is not for inventory tracking but specifically for loading process monitoring.

Dedicated Loading Monitoring: Radar Sensor Installed in Enclosed Cavity

During loading, powder material enters the tank by gravity or pneumatic conveying, gradually forming a naturally angled heap. The radar sensor monitors the height changes and growth trends of this heap in real-time, providing the control system with essential reference data.

Key distinctions from traditional silo or warehouse measurement include:

- Not used for trade measurement: The final loading weight is confirmed by weighing systems; the radar does not generate settlement data or serve as a delivery reference. Its focus is on whether the tank space remains within safe limits during loading.

- Not for long-term storage: Unlike continuous inventory monitoring in silos, vehicle loading is short-duration, highly dynamic, and the radar level measurement operates only during loading. Once loading ends, it exits the critical control process.

- High-risk, short-duration measurement: In high-speed loading, dusty, and opaque tank conditions, the radar provides real-time risk awareness and safety boundary assessment, detecting when material levels approach limits rather than recording final results.

Thus, the correct engineering definition for this application is filling-port radar level measurement, not traditional storage measurement.

2. Industry Challenges: Weighing Shows “How Much,” But Not “Where”

In automated bulk powder loading systems, weighing systems are essential to determine final load weight. However, relying solely on weighing systems cannot fully cover loading risks:

- Loading is “invisible”:

Cement and fly ash generate large amounts of airborne dust during loading. The filling port and tank interior are virtually unobservable by human or optical means.- Photoelectric or laser sensors are easily blocked by dust.

- Contact probes can be buried or worn by material.

- Manual judgment is impossible in unmanned systems.

- High flow dynamics cause weighing lag:

Powder materials have good flowability; under high-speed loading, material continues to flow due to gravity and pneumatic inertia even after the weighing system signals stop. This is particularly evident when:- High flow rates are used to reduce loading time.

- The tank is near full capacity.

- Multiple vehicles operate consecutively, with frequent system start-stop cycles.

As a result, although weight targets are reached, the internal material level may already approach or exceed safety limits, increasing the risk of spillage and dust emissions.

- Overfilling disrupts dust-free goals:

Overfill often causes material to escape through dust ports, safety valves, or sealed connections, contaminating the loading area and equipment, increasing cleaning and maintenance workload, and raising environmental compliance risks. - Radar adds “visibility” to the system:

Installed inside the filling port’s enclosed cavity, the radar sensor points vertically toward the forming material heap, avoiding the turbulent free-fall zone and minimizing signal fluctuations. This optimized placement ensures stable operation under high dust and disturbance, providing direct, actionable information on tank internal space.

The radar does not measure final weight but offers a critical judgment of remaining safe space, enabling the control system to slow down or stop loading before risks occur.

3. Measurement Structure: Why the Filling Port Placement

From an engineering perspective, placing the radar inside the filling port provides clear advantages:

- Proven in field applications:

Validated in cement, limestone powder, and grain powder vehicle loading systems, this placement shows superior measurement accuracy, response speed, and reduced maintenance compared to traditional top or external installations. - Avoids free-fall interference:

Powder turbulence in free-fall generates airflow, dust, and turbulence, causing multi-path reflection and noise. Internal placement reduces these effects, stabilizing radar signals. - Compatible with enclosed, dust-free systems:

Direct integration with sealed tanks or loading pipes avoids extra openings or external supports, preserving dust-free, safe operation. - Non-contact and long-term reliable:

Airborne radar level measurement prevents dust adhesion, corrosion, and wear. Even with varying material properties (poor flow, caking, corrosive), the radar operates stably over time.

4. System Coordination: Radar Level Measurement and Weighing

A mature automated loading system typically uses:

- Weighing system: controls target load weight.

- Radar sensor: monitors tank space safety.

- Control system: interlocks both signals.

When the radar detects that material approaches a set height, the system can reduce or stop flow in advance, preventing overfill due to inertia. Radar Level Measurement

Conclusion

In bulk powder vehicle automated loading, radar level measurement focuses on remaining safe tank space, not total material weight. Internal placement inside the filling port avoids free-fall interference, stabilizes signal return, integrates with dust-free enclosed systems, and enables long-term reliable operation under high-dust, dynamic conditions. With loading systems moving toward enclosed, automated, and unmanned operation, radar level measurement is evolving from an optional feature to a standard safety configuration, ensuring both loading accuracy and operational safety. Radar Level Measurement