Reliable Oil Tank Point Level Detection in Rotor Gearboxes with Jiwei Vibrating Level Switch

Oil Tank Point Level Detection in Rotor Gearbox Applications

Vibrating level switches are essential in modern wind energy systems for maximizing operational efficiency and turbine uptime. The rotor gearbox, which transfers kinetic energy from turbine blades to the generator, relies on precise oil level monitoring in its oil tank to maintain integrity and consistent performance. Without adequate lubrication, increased wear, overheating, and eventual gearbox failure can occur, leading to costly downtime.

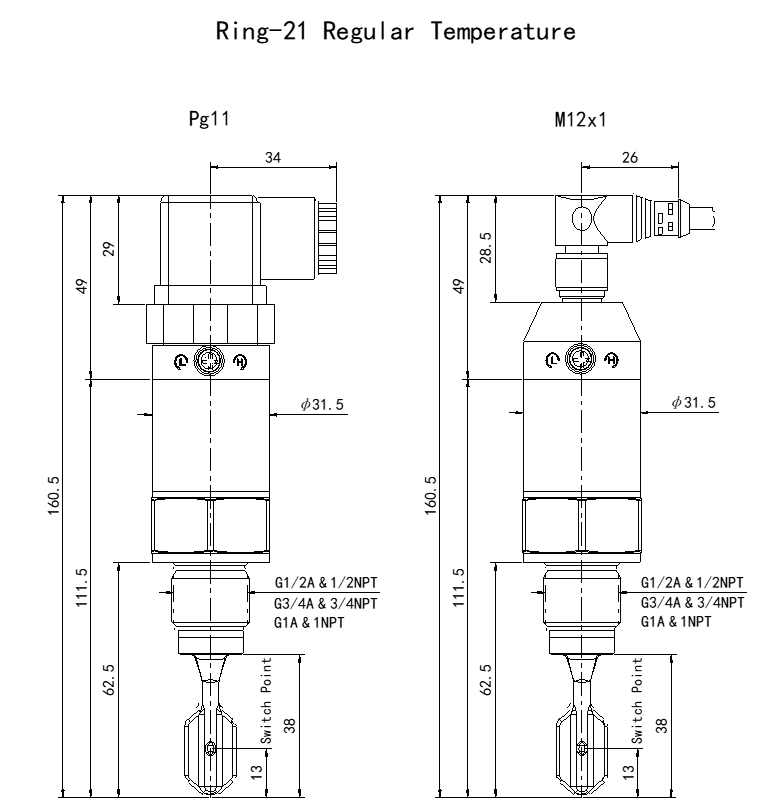

Jiwei Automations, a leading manufacturer of industrial level measurement instruments, offers the Ring‑21 vibrating level switch, a highly reliable and compact solution designed specifically for point level detection in gearbox oil tanks. Engineered to perform reliably in demanding and harsh environments, the Ring‑21 provides non-contact, media-independent switching, making it an ideal choice for wind turbine applications where precision and durability are critical. Its compact size allows for easy installation even in tight spaces, ensuring continuous monitoring of oil levels to prevent equipment damage and costly downtime.

In addition, Jiwei’s Ring-21 vibrating level switch is a versatile and compact liquid level switch designed for precise detection of limit levels in liquids. Independent of mounting position, the Ring-21 ensures reliable detection with millimeter accuracy. It can be used as an empty or full level detector, dry run protection, overfill protection, or pump protection in tanks and pipelines. With its economical design and maximum reliability, the Ring-21 provides a safe and cost-effective solution for liquid level monitoring across various industrial applications, complementing its capabilities in solid and viscous media detection.

Why Choose Jiwei Ring‑21 for Rotor Gearbox Oil Tanks?

✔ Highly Reliable, Media-Independent Switching

The Ring‑21 vibrating level switch operates based on the vibration frequency principle and provides a highly dependable switching point, regardless of changes in the oil’s dielectric constant, viscosity, temperature, or aeration. This makes it particularly effective for gear oil with foaming tendencies or additives.

✔ Dry-Run Protection and Wear Prevention

Ensuring a continuous oil supply to all moving gearbox components is essential to prevent metal-to-metal contact, which causes excessive wear. The Ring‑21 acts as a dry-run protection device, detecting low oil levels promptly and triggering alarms or shutdowns before damage occurs.

✔ Compact and Robust Design

With its short fork length (as low as 40mm) and compact housing, the Ring‑21 can be easily integrated into tight spaces, such as those found in nacelle-mounted gearboxes. Its rugged stainless steel construction ensures resistance to mechanical vibration and temperature fluctuations.

✔ Plug-and-Play Installation

Unlike conventional float switches or capacitive sensors, Ring‑21 requires no calibration with process media, significantly reducing commissioning time. The device can be installed and wired quickly, minimizing downtime and labor costs during retrofits or maintenance.

✔ Versatile Output Options

The Ring‑21 supports relay, PNP/NPN, and 8/16mA current outputs, allowing seamless integration into existing turbine control systems or SCADA networks.

Key Technical Features of Jiwei Ring‑21 Vibrating Level Switch

| Feature | Description |

|---|---|

| Switching Principle | Vibrating fork technology |

| Fork Length | Short type: 38mm |

| Medium Compatibility | Gear oil, lubricants, foaming and viscous oils |

| Installation Orientation | Horizontal or vertical |

| Process Connection | Threaded, custom options |

| Electrical Output | Relay, PNP/NPN, 8/16mA |

| Ambient/Process Temperature | –40°C to +150°C |

| IP Rating | IP66/IP67 |

Conclusion: Optimize Gearbox Health and Turbine Uptime

By adopting Jiwei’s Ring‑21 vibrating level switch for rotor gearbox oil tank level monitoring, wind turbine operators gain a cost-effective, reliable, and compact solution that minimizes wear, ensures full lubrication, and improves system safety. Designed to perform in harsh, space-limited environments, the Ring‑21 stands out for its ease of use, high durability, and maintenance-free operation.

Whether you’re designing new turbines or upgrading legacy systems, the Ring‑21 provides long-term peace of mind with precision level detection and robust engineering that matches international standards. Choose Jiwei Automations for your wind energy application—and ensure your turbines operate at full efficiency.

Target Keywords vibrating level switch, oil level detection, wind turbine gearbox oil tank, rotor gearbox lubrication, Jiwei Ring‑21, dry-run protection, gear oil level switch, point level measurement in wind turbine, compact oil level sensor