Ash Silo High-Level Measurement & Solution

In coal-fired power plants, waste incineration plants, and cement production lines, ash silos serve as storage units for fly ash or other dust-containing materials. The reliability of level measurement in ash silos directly impacts the safety and continuity of system operations. However, due to high dust concentration and complex environmental conditions inside the silos, traditional level measurement instruments are easily affected by dust adhesion, high temperatures, material bridging, and vibration, which may result in false alarms, missed signals, or even equipment damage.

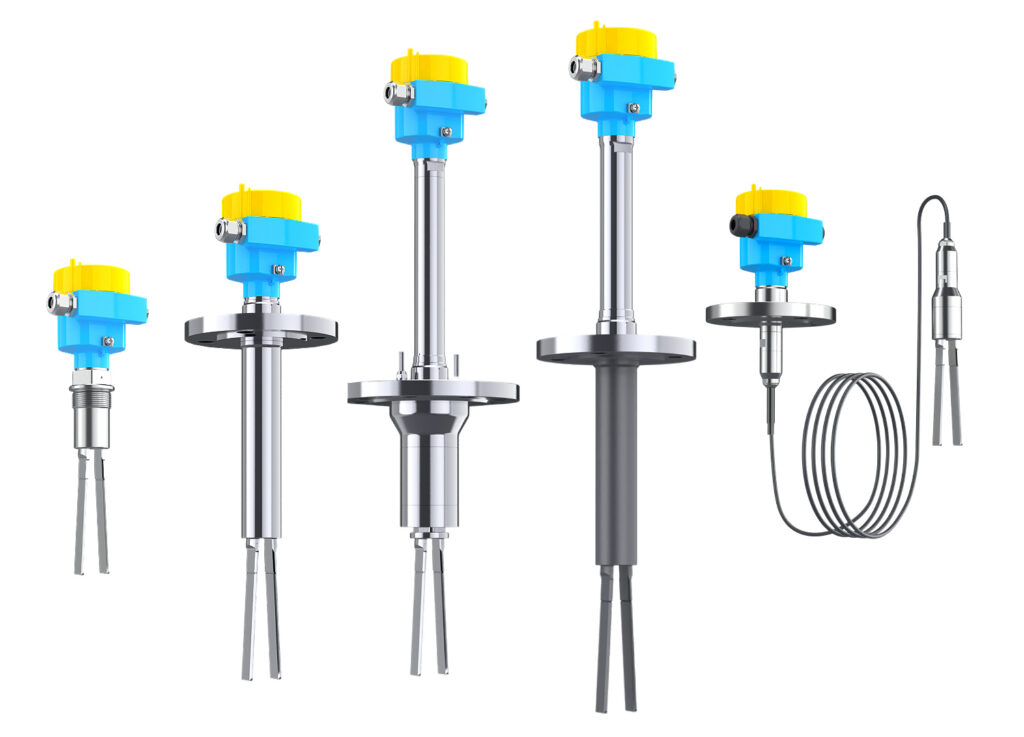

To address these challenges, Jiwei Automations has developed the Fork-11 Fork Level Switch, designed with a unique structure and high reliability, providing an effective solution for high-level measurement in ash silos.

Key Challenges in High-Level Measurement of Ash Silos

Ash silos represent a typical high-dust, high-temperature, and high-vibration storage environment. The main challenges in level measurement include:

1. Severe Dust Environment

High concentrations of fine dust inside ash silos easily accumulate on probe surfaces, causing signal attenuation, inaccurate readings, or false triggering. Traditional capacitive, RF admittance, or ultrasonic level sensors often require frequent cleaning and maintenance, resulting in reduced stability and higher operational costs.

2. Complex Material Accumulation and Arching

Fly ash and other fine-grained materials are prone to bridging or uneven accumulation, especially at the end of pneumatic conveying or static conditions. Improper placement of level sensors near these zones may cause measurement errors, affecting the accuracy of high-level alarms.

3. Harsh High-Temperature Conditions

Some ash silos operate at several hundred degrees Celsius, particularly near dust collector outlets or hot ash systems. Conventional sensors may fail under such conditions due to electronic aging or seal degradation, significantly shortening device lifespan.

4. Frequent Vibration and Shock

Ash silos are subject to airflow pulses, material impact, and unloading vibrations during operation. These disturbances may affect electronic circuits or mechanical structures, leading to zero drift or signal loss in conventional level sensors.

In summary, high-level measurement in ash silos is highly challenging due to the combination of dust, high temperatures, vibration, and complex material behavior, demanding superior reliability and adaptability from level switches.

Fork-11 Fork Level Switch Solutions

Jiwei Automations’ Fork-11 Fork Level Switch has been systematically optimized to address the complex working conditions of ash silos, offering clear advantages in structural design, vibration performance, and signal processing.

1. Strong Dust Resistance

The Fork-11 probe is made of 316L stainless steel with a smooth, seamless surface that prevents dust accumulation. Its fork resonance frequency and amplitude are carefully optimized to maintain stable vibration even in high-dust environments.

Its internal circuitry features an intelligent vibration detection algorithm. When dust adheres to the probe or minor material accumulation occurs, the system automatically identifies vibration changes and distinguishes true signals from interference, preventing false alarms. Even in long-term high-dust environments like power plant ash silos or dry ash bins, the Fork-11 maintains stable operation with minimal maintenance.

2. Adapting to Complex Material Accumulation

Fork-11 is highly sensitive to irregular material accumulation. It accurately detects high-level conditions even when ash layers are uneven, sloped, or temporarily surging. This ensures reliable high-level alarms and can serve as a safety overflow protection signal, preventing silo overpressure or discharge system blockage.

3. High-Temperature Resistance for Extreme Conditions

The high-temperature version of Fork-11 can withstand up to 400°C, meeting the needs of coal-fired power plants, waste-to-energy systems, and hot ash handling applications.

Its electronics are mounted with thermal isolation and optimized heat dissipation paths, ensuring stable measurements without drift. The fork material undergoes special heat treatment and sealing, enabling long-term operation in hot, dusty environments without failure.

4. Excellent Vibration and Shock Resistance

Fork-11 features reinforced mechanical structure with high-strength connections between the probe and flange, as well as anti-interference filtering circuits in the electronics.

Whether subjected to periodic airflow vibration or impact from material unloading, the Fork-11 consistently delivers stable output signals. Its design has passed rigorous vibration tests, making it suitable for heavy-duty industrial applications.

Advantages of Fork-11 in Ash Silo Applications

| Advantage | Feature | Technical Detail |

|---|---|---|

| Dust Resistance | Unaffected by dust adhesion | Smooth probe + intelligent detection algorithm |

| Material Accumulation | Accurate detection under uneven layers | High-frequency vibration sensitivity |

| High-Temperature | Up to 400°C | Thermal isolation + heat-treated probe |

| Vibration Resistance | Stable signal output | Anti-interference electronics + reinforced structure |

| Low Maintenance | Long-term operation without cleaning | Minimal intervention required |

These features make Fork-11 a highly reliable and cost-effective domestic alternative to imported fork level switches for ash silo high-level monitoring.

Conclusion

Accurate ash silo level measurement requires instruments capable of withstanding dust, high temperatures, vibration, and complex material accumulation while providing stable and precise signals. The Fork-11 Fork Level Switch meets these requirements with its combined high-temperature resistance, dust-proof design, and shock-resistant structure.

As demand grows for intelligent and safe ash silo management, the Fork-11 will continue to expand its applications, providing safer, more efficient level control solutions for industrial automation.