How Jiwei’s Advanced Level Switches Enhance Graphene Powder Handling and Other Industrial Applications

Introduction to Graphene Powder and Its Industrial Importance

Graphene powder, a revolutionary material derived from a single layer of carbon atoms arranged in a hexagonal lattice, is transforming industries worldwide. Known for its exceptional strength, conductivity, and flexibility, graphene is used in applications ranging from electronics to energy storage and advanced composites. However, handling and measuring this fine powder comes with unique challenges. Accurate level measurement is critical in industries processing graphene powder to avoid operational issues like material overflow, underfill, or inefficient processes.

Challenges in Measuring Graphene Powder

Graphene powder’s fine particle size and low bulk density make it difficult to measure using traditional methods. These challenges are exacerbated when the powder is stored in silos or tanks where static build-up or bridging could affect measurement accuracy. For industries involved in graphene powder production, precise material level detection systems are essential to ensure smooth, efficient operations.

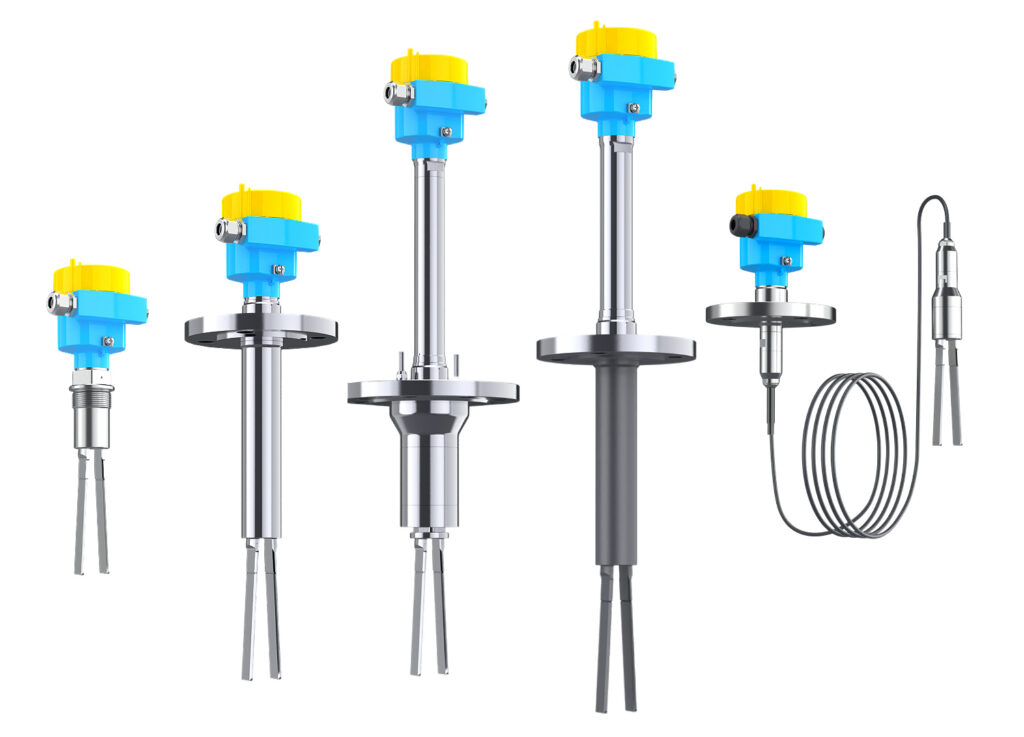

This is where Jiwei’s vibrating rod and tuning fork level switches offer industry-leading solutions. These advanced devices are designed to handle fine powders, like graphene, with high accuracy, reliability, and versatility in harsh industrial environments.

Jiwei’s Vibrating Rod Level Switches: Perfect for Fine Powders

Jiwei’s vibrating rod level switches are engineered to provide highly sensitive and reliable level detection for materials like graphene powder. The first made-in-China vibrating rod level switch features innovative double vibration rods, setting a benchmark in the industry. This design ensures superior performance even in challenging environments. Here are the key advantages of these switches:

- High Sensitivity: Achieved through precise adjustment of resonant vibration frequencies, Jiwei’s vibrating rod level switches are suitable for almost all granular bulk solid applications, including fine-grained solids with densities as low as 0.02 g/cm³.

- Temperature Tolerance: The switches can withstand process temperatures up to 250°C and even ultra-high temperatures of 400°C with water or air cooling, making them ideal for high-temperature industrial environments.

- Versatile Application: These switches perform excellently in liquids, excelling at precipitate interface measurements. They can also be used reliably in tall and narrow silos, oscillating environments, and liquid sediment measurement.

- Superior Anti-Buildup Performance: The design of the vibrating rod level switch ensures superior anti-buildup performance, reducing maintenance needs even in viscous and adhesive mediums.

- Enhanced Durability: Built with abrasion-resistant double-rod construction and self-diagnostic functions for precise fault detection, these switches ensure reliability in harsh conditions.

- Maintenance-Free Operation: Jiwei’s vibrating rod level switches operate without the need for frequent maintenance, unaffected by changes in product properties.

The 316L and 318 S13 materials used for the probe ensure excellent corrosion resistance, further enhancing the switch’s longevity in harsh environments.

Jiwei’s Tuning Fork Level Switches: Ideal for Light Powders

Jiwei’s tuning fork level switches are also designed to excel in applications involving fine powders like graphene. These switches operate based on the principle of resonance, detecting material presence by changes in vibration frequency. Key benefits of Jiwei’s Fork-11 tuning fork level switches include:

- Precise Frequency Adjustment: The fork tines are designed for optimal performance, and the resonant frequency is precisely adjusted, allowing the switch to be used with powders and flakes having bulk densities as low as 0.008 g/cm³.

- Avoids Buildup: The tuning fork level switch is especially effective in preventing material buildup, a common issue in the handling of fine-grained powders.

- Versatility with Suspension Cable: When equipped with a suspension cable, the Fork-11 can be applied in tall and narrow silos, making it ideal for industries processing fine powders like graphene.

- High Temperature Resistance: With the ability to withstand process temperatures up to 400°C, Jiwei’s tuning fork level switches excel in high-temperature applications, ensuring reliable performance even under extreme conditions.

- Self-Diagnostic Capabilities: The tuning fork switches are equipped with a strong self-diagnostic function, which helps to precisely locate faults and minimize downtime.

- Corrosion-Resistant Materials: The wetted parts are made from durable, corrosion-resistant 316L stainless steel, ensuring longevity even in the harshest environments.

These features make Jiwei’s Fork-11 tuning fork level switches particularly suited for measuring graphene powder and other fine materials with high accuracy.

Conclusion

As graphene powder continues to find its way into more industries, having reliable, high-precision level measurement systems is essential. Jiwei’s vibrating rod and tuning fork level switches are designed to meet the unique challenges of measuring fine powders like graphene. These switches provide exceptional sensitivity, durability, and versatility, making them the ideal choice for industries requiring precise material level detection.

Whether you are managing graphene powder in an advanced composite production line or another industrial setting, Jiwei’s level switches ensure smooth operations, reduce downtime, and enhance process efficiency. By integrating Jiwei’s cutting-edge technologies, industries can achieve more accurate material management, driving both safety and productivity.