Wet Gypsum Storage Hall Monitoring: 5 Essential Level Sensing Solutions

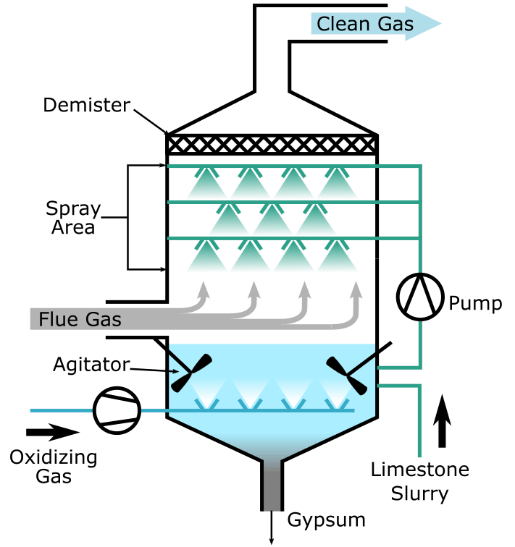

A Wet Gypsum Storage Hall is a dedicated facility at a power plant’s wet flue gas desulfurization (FGD) unit where the calcium sulfate (gypsum) byproduct is dewatered and stockpiled. After limestone slurry in the absorber produces gypsum, the slurry is dewatered (e.g. via hydrocyclones) and pumped into the storage hall. In this hall the wet gypsum is further dewatered and stored as a solid cake for shipment or disposal. Monitoring the gypsum level in the storage hall is critical: accurate level sensors report the stockpile height and inventory, enabling optimized transport, preventing overflow, and ensuring continuous FGD operation.

Effective gypsum stockpile monitoring relies on point-level switches. Point switches (e.g. vibrating forks) provide on/off alarms at critical levels. For example, level sensors are needed to determine the stockpile height of the gypsum and quantity of the stock to optimize transportation management. In practice, these technologies are used to ensure reliable measurement under harsh conditions (dust, moisture, abrasive material). wet Gypsum Storage Hall Wet Gypsum Storage Hall

Role of the Wet Gypsum Storage Hall in FGD Systems

In wet FGD systems, power-plant flue gas is scrubbed with limestone slurry to remove SOx. The chemical reaction produces gypsum (CaSO₄·2H₂O) as a solid byproduct. This gypsum slurry is removed from the absorber and sent to the Wet Gypsum Storage Hall, where it is thickened, filtered, and stockpiled. The wet gypsum is further dewatered and processed in the wet gypsum storage hall, producing a useful by-product. In other words, the storage hall is essentially a large dewatering tank or building where gypsum cakes accumulate. Wet Gypsum Storage Hall

Once in wet gypsum storage hall, gypsum is often piled by conveyors or pumps. The pile height will vary with production and transport schedules. It is important to know how much gypsum is on hand. Too little inventory can interrupt sales/shipment; too much can overload conveyors or violate storage permits. Therefore, point alarms are installed throughout the hall. Typically, sensors are mounted on roof trusses or conveyors to measure the pile’s surface. These instruments must tolerate a harsh environment: wet (moist) gypsum, corrosive limestone residues, dust, and possible rapid changes during filling.

Importance of Level Measurement in Wet Gypsum Stockpiles

Accurate level sensing in the wet gypsum storage hall enables several critical functions:

- Inventory management: Knowing the gypsum pile height/volume helps operators plan transport (trucks, railcars) efficiently. Stockpile measurements optimize transportation management by indicating the amount of material ready for dispatch.

- Process control: The FGD chemical process depends on a continuous limestone feed. If the gypsum pile gets too high, conveyors may be stopped or capacity limited. Conversely, if empty, upstream slurry may back up. Level sensors can interlock the feed pumps or alarms accordingly.

- Safety and overflow protection: Overfilling the hall can cause spillage or structural overload. High-level switches act as hard safeties to shut down slurry feed if needed.

- Efficiency and maintenance: Point-level switches are maintenance-free and immune to dust. This keeps measuring systems reliable under the gypsum dust and debris that would foul other devices.

In practice, point-level switches are often used. For example, several point-level switches at various elevations provide full/empty alarms or conveyor cut-outs. In conveyors and chutes feeding the pile, additional switches protect equipment from jamming or overfilling.

Point-Level Switch Technologies for Wet Gypsum Storage Hall

Point-level detectors (level switches) provide simple on/off alarms:

Vibrating tuning fork level switches – A tuning fork vibrates at a fixed frequency. When buried in gypsum, its vibration amplitude is damped, triggering a switch. Fork level switches are compact and fast-acting. They can detect very low-density material (as low as 0.008 g/cm³), making them suitable for gypsum fines or dry dust layers.

Vibrating rod level switches – A nested dual-tube structure that detect solids. The dual-rod level switch is designed to handle coarse and heavier materials, such as gypsum. The dual-rod structure enhances mechanical stability and sensitivity, reducing the risk of false trips and minimizing wear over time. This design is particularly suitable for applications where false activation needs to be avoided, ensuring the switch only triggers when there is an actual change in material level. It is ideal for applications that require consistent material handling and durable switches.

Rotary paddle level switches – A motor turns a small paddle. Contact with gypsum stops the paddle, triggering an alarm. Paddle switches are simple and inexpensive, but have moving parts that can wear or jam in heavy sticky gypsum.

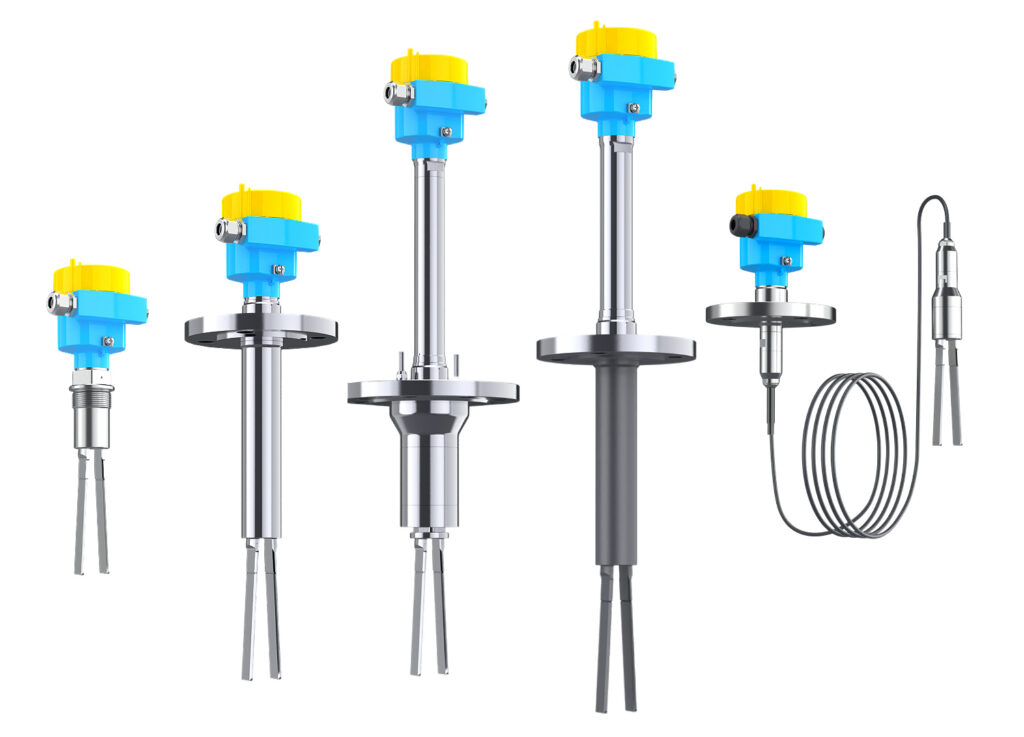

Jiwei Fork-11 and Tube-11 Level Switch Solutions

For point-level detection in a Wet Gypsum Storage Hall, Jiwei Automations offers two recommended products:

- Jiwei Fork-11 Tuning Fork Level Switch – A rugged tuning-fork sensor for fine solids. The Fork-11 is designed to avoid material buildup on the tines, and it can detect extremely low densities (down to 0.008 g/cm³). This makes it ideal for sensing fine gypsum dust or powder that might linger on top of the pile. It is available in gas and dust explosion-proof (Ex) versions, ensuring reliable operation in environments with both flammable gases and combustible dust, such as power plants.

- Jiwei Tube-11 Vibrating Rod Level Switch – The Jiwei Tube-11 Vibrating Rod Level Switch features a vibrating rod sensor, with the option of using a suspension cable for high or hard-to-reach applications, such as tall stockpiles or silos. It is offered in explosion-proof (Ex) versions for both gas and dust, ensuring dependable performance in environments with the presence of flammable gases and combustible dust. Tube-11 also comes with industrial certifications and self-diagnostic capabilities, ensuring reliable operation in challenging conditions.

These Jiwei switches complement continuous sensors. For example, a Fork-11 or Tube-11 gives a reliable high-level alarm or prevents the conveyors from overfeeding when the pile reaches a set elevation. In field usage, choosing between Fork-11 vs. Tube-11 depends on material characteristics: Fork-11 excels with light, dusty gypsum; Tube-11 handles coarse, abrasive gypsum.

Comparison of Point-Level Switch Technologies

| Technology / Product | Measurement Type | Typical Application / Comments |

|---|---|---|

| Jiwei Fork-11 (tuning fork) | Point level switch | Detects fine/powdery gypsum; very low density (0.008 g/cc); ideal for dusty environments. |

| Jiwei Tube-11 (vibrating rod) | Point level switch | Vibrating dual-rod on cable; suits heavy/coarse gypsum in tall silos; overfill detection; robust in abrasion. |

| Jiwei Spin-11 Rotary Paddle Level Switch | Point level switch | Simple mechanical switch; cheap; good for bulk solids; prone to wear or jamming in sticky gypsum. |

Best Practices

- Placement: Ensure point sensors like Fork-11/Tube-11 are mounted above expected maximum fill levels.

- Calibration and Diagnostics: Use sensors with self-test or remote diagnostics.

- Environment: Account for moisture and alkalinity. Use corrosion-resistant materials (stainless steel probes, rugged housings).

- Safety: For overfill protection, use redundant switches at critical heights. Ensure any electrical sensors in the hall are rated for Explosive Dust atmospheres (e.g. Ex certified).

Conclusion

In summary, point-level switches are crucial for safe and efficient wet gypsum storage hall operations. Devices like the Jiwei Fork-11 and Tube-11 provide reliable detection tailored to different gypsum characteristics, from fine dust to coarse chunks. By implementing these switches with proper placement and redundancy, power plants can prevent overflows, protect equipment, and maintain smooth FGD processes.