How to Test Fork Level Switch Correctly?

Incorrect Testing Method: Holding the Fork

When accepting and testing fork level switches, many customers habitually hold the fork body to observe whether the instrument reacts. However, this testing method is not applicable to Jiwei Ring-11 fork level switches and may even lead to incorrect judgments or damage to the equipment.

It is worth noting that some low-end fork level switches on the market may still trigger an action by holding the fork. This is due to their simple detection principles and poor resistance to environmental interference. In contrast, Jiwei Ring-11 employs more advanced detection technology, with a different fork response mechanism, meaning the traditional method of holding the fork is not suitable for testing.

So, why doesn’t the “hold test” method work for the Ring-11? What is the correct testing method? This article will detail the technical principles of the Ring-11, common misconceptions, and the correct testing methods, helping users ensure the reliability and longevity of the equipment.

Why the “Hold Test” Doesn’t Work for Ring-11

Standard fork level switches on the market typically use simple mechanical vibration detection, which is less sensitive. As a result, holding the fork can cause the switch to mistakenly detect liquid contact. However, these low-end designs are more prone to false triggers due to environmental vibrations, temperature fluctuations, and other factors.

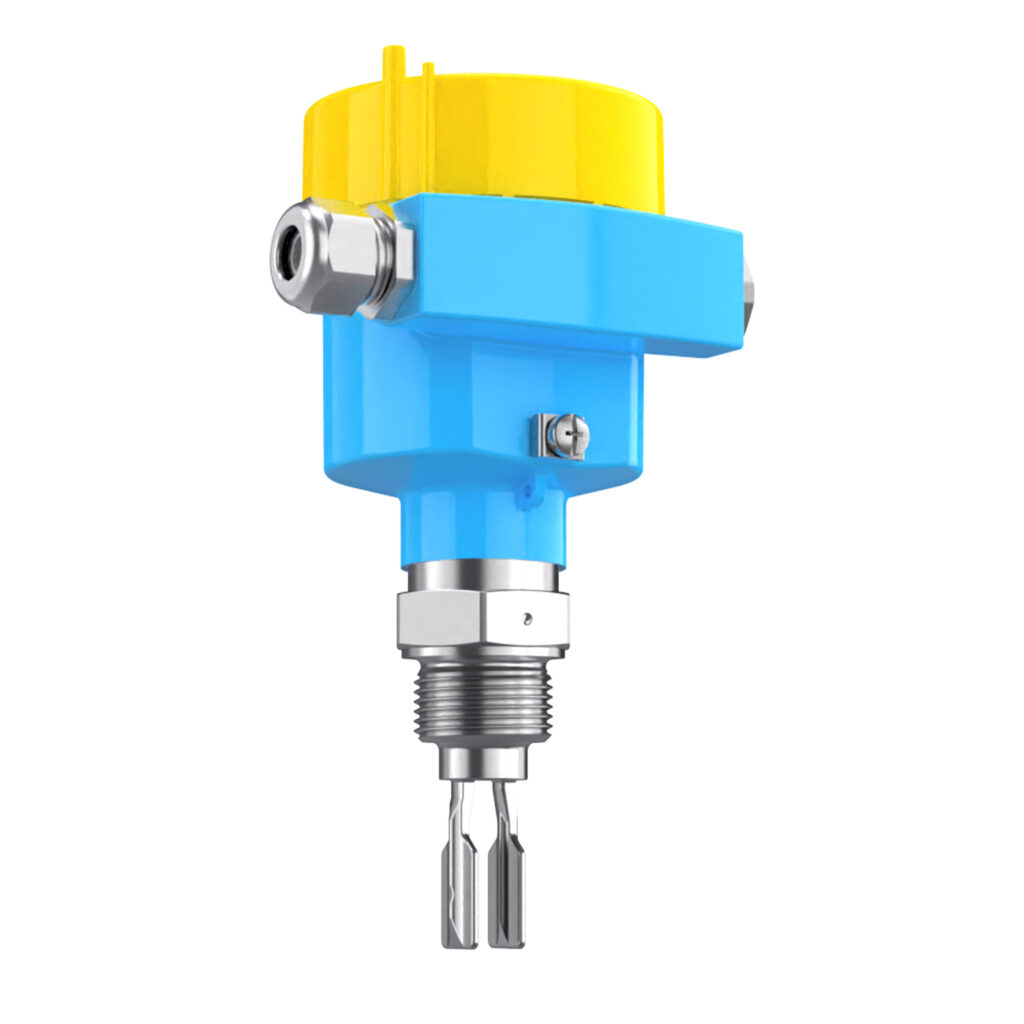

Jiwei Ring-11 Fork Level Switch

Jiwei Ring-11 adopts a more precise vibration frequency analysis technology, differing from cheaper products:

- High-precision frequency detection algorithm: Ring-11 determines liquid contact by measuring the vibration frequency of the fork, rather than relying on simple vibration sensing. The effect of holding the fork is insufficient to cause a significant frequency change, thus no switch action occurs.

- High temperature resistance up to 280°C, far exceeding the industry standard of 220°C: Jiwei Ring-11 Fork Level Switch features advanced high-temperature design, capable of stable operation in environments up to 280°C, significantly outperforming the typical industry standard of 220°C, ensuring reliable level detection even under extreme temperature conditions.

- Prevention of damage: Low-end products may allow holding tests, but Ring-11, due to its high-sensitivity detection mechanism, could suffer damage or accuracy degradation if excessive force is applied.

Correct Testing Method: Liquid Immersion Test

Since Ring-11 cannot be tested by holding the fork, the recommended method for verifying its functionality is the liquid immersion test, with the following steps:

- Step 1: Prepare an appropriate testing medium

Choose water, oil, or another suitable liquid based on the application, ensuring that the liquid fully covers the fork probe. - Step 2: Power on and check the initial state

Connect the power supply and ensure the Ring-11 is in the normal standby state. Observe the initial signal output, which should typically show a “no level” status. - Step 3: Carefully immerse the fork completely in the liquid

Avoid shaking the fork vigorously and ensure that it is fully immersed in the liquid without bubbles or tilting affecting detection. Observe the instrument’s signal output—when the fork contacts the liquid, the vibration frequency will change, and the switch should trigger the alarm signal. - Step 4: Confirm signal change

After the fork is fully immersed in the liquid, the switch output status should change, usually triggering the LED indicator, relay action, or signal transmission. Once the fork is removed, the signal should return to the no-level state, ensuring proper reset.

Jiwei Ring-11 VS Low-end Fork Level Switches

| Comparison Item | Jiwei Ring-11 | Low-end Fork Level Switches |

|---|---|---|

| Detection Principle | Frequency change detection, more precise | Mechanical vibration detection, prone to false triggering |

| Anti-interference Ability | Strong, can exclude environmental vibrations | Weak, easily affected by temperature and external force |

| Hand-held Test | Ineffective, requires liquid immersion | Can trigger action, simple but inaccurate |

| Reliability | High, suitable for complex applications | Low, prone to false alarms or missed detections |

| Durability | Long-lasting, robust design | Short lifespan, prone to damage |

Summary: Avoid Misconceptions, Ensure Accurate Testing

- Incorrect Method: Holding Test (applies to low-end products but not to Ring-11)

❌ Light grip won’t change frequency

❌ Excessive force may damage the fork

❌ Cannot accurately simulate liquid contact state - Correct Method: Liquid Immersion Test

✔ Use water or suitable liquid for testing

✔ Ensure the fork is fully immersed, observing alarm signals

✔ Signal should return to normal after removing the fork

Unlike cheap fork level switches on the market, Jiwei Ring-11 employs more advanced vibration frequency detection technology. It not only differs in testing method but also far outperforms low-end products in anti-interference ability, accuracy, and reliability. By choosing the correct testing method, users can ensure their equipment meets application needs and avoid the risks associated with incorrect judgments or misoperations.