Level Measurement Upgrade: Replacing Siemens Fork Level Switch with Jiwei Ring-11

In the chemical and process industries, accurate level measurement in key storage tanks directly affects equipment safety, process stability, and production continuity. For many years, Siemens tuning fork level switches have been widely used in storage tanks, separators, and process vessels due to their mature technology and simple structure. However, as industrial automation continues to advance, users have gradually encountered challenges such as unstable signals, deposits on the sensor surface, frequent maintenance, and limited system integration capability.

Recently, a chemical enterprise located in the High-tech Zone of Zibo, Shandong Province, decided to upgrade the level measurement and control systems of several critical tanks by replacing its existing Siemens tuning fork switches with Jiwei Ring-11 vibrating fork level switches. This upgrade significantly improved measurement reliability, reduced maintenance costs, and optimized DCS system integration efficiency.

Level Measurement Upgrade: From Siemens to Jiwei Ring-11

Background: Limitations of the Siemens Fork Level Switch

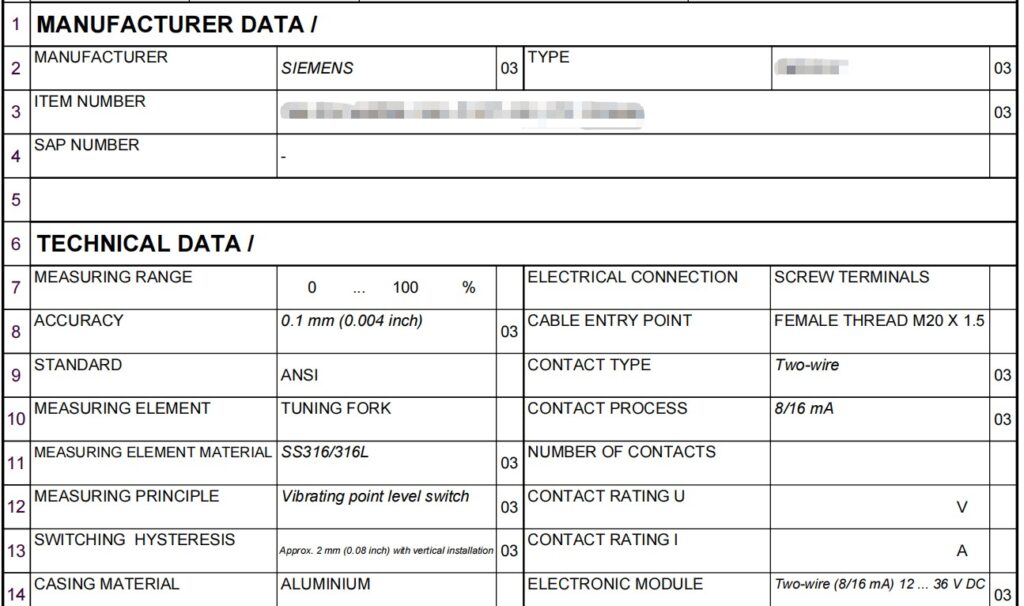

Based on on-site operating data, the Siemens fork level switch featured the following specifications:

- Sensing Element: Tuning fork

- Material: SS316/316L stainless steel

- Accuracy: 0.1 mm (0.004 in)

- Switch Hysteresis: Approx. 2 mm (0.08 in)

- Electrical Interface: Screw terminals, two-wire, 8/16 mA output

- Installation: ANSI flange or threaded connection

- Housing Material: Aluminum

Although the specifications appeared adequate on paper, field engineers observed several issues during long-term operation:

- Fork jamming: Fine sediment adhered to the fork, reducing sensitivity and causing delayed switching.

- Signal instability: Vibration, level fluctuations, or condensation occasionally led to false or missed alarms.

- Frequent maintenance: Regular cleaning and inspection were required, increasing labor costs.

- Limited system compatibility: The two-wire output and limited contact types restricted integration with modern DCS systems.

Therefore, the plant required a level switch that was reliable, maintenance-free, and easily integrated into automated process systems.

Technical Selection: Advantages of Jiwei Ring-11 Vibrating Fork Level Switch

After comparing several technologies—including hydrostatic, capacitive, and conventional tuning fork types—the enterprise selected the Jiwei Ring-11 vibrating fork level switch for its superior stability and adaptability.

Key Advantages of the Ring-11

- Vibration-based detection with fast response:

Utilizing vibration resonance, the Ring-11 detects liquid level changes with exceptional speed and minimal delay. It remains unaffected by foam, light buildup, or variations in liquid viscosity. - Corrosion-resistant materials:

The sensing element is made from 316/316L stainless steel, ensuring durability and reliability in a wide range of chemical media. - High sensitivity:

Provides fast, stable switching at critical level points to ensure process safety. - Excellent system compatibility:

Supports two-wire 4–20 mA or 8/16 mA outputs, easily connecting to DCS, PLC, and other automation systems for smart level control. - Enhanced anti-interference performance:

Maintains stable output even under vibration, fluctuating levels, or slight deposits—offering improved reliability over the Siemens model. - Compact, easy-to-install design:

With standard flange connections and a compact body, Ring-11 can directly replace existing devices without pipeline modification, reducing downtime.

Distinctive Features

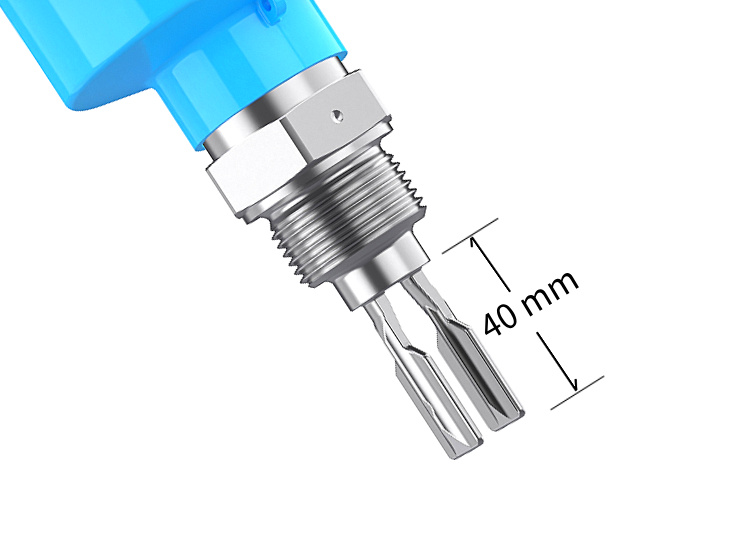

Fork length is only 40 mm, enabling precise installation in pipelines and narrow spaces where traditional instruments cannot fit.

Low-density liquid detection

With precise frequency tuning, it detects liquids with densities as low as 0.5 g/cm³, extending its use to light hydrocarbons and other low-density media.

Strong anti-interference capability

Proprietary design ensures reliable performance under foam, bubbles, viscous liquids, and vibration conditions.

Flexible output options

Offers relay, two-wire, NAMUR, and transistor outputs for broad system compatibility.

Comprehensive certifications

Certified to SIL2/3, EAC, RoHS, REACH, 3C, CE, and both intrinsic safety (Ex ia) and explosion-proof (Ex d) standards for gas and dust environments.

High reliability design

Based on vibration frequency detection, the structure is rugged and built for long-term stability under extreme operating conditions.

Industry standard compliance

Meets food-grade safety standards, ensuring hygienic and reliable performance in food and pharmaceutical applications.

Outstanding temperature resistance

Handles process temperatures up to 400°C, ensuring reliable measurement in chemical, petroleum, and pharmaceutical high-temperature environments.

Installation and Commissioning

At the site, the Ring-11 switches were installed using the original Siemens mounting points.

The aluminum housing and robust fork structure ensured mechanical stability on the ANSI flange.

Electrical wiring was straightforward, using screw terminals with a two-wire 8/16 mA signal directly integrated into the DCS system.

With a response delay of less than 0.5 seconds, the switch adapted automatically to vertical installation without calibration.

Field tests under both steady and fluctuating liquid levels confirmed fast, accurate switching without false alarms. The entire installation was completed efficiently, reducing planned downtime to less than one day, which greatly improved production continuity.

User Feedback and Application Value

During installation, engineers reused the existing Siemens mounting points and completed the replacement in less than a day. No changes were needed for flanges, wiring, or signal settings. After connection, the DCS system immediately recognized the 8/16 mA signal, and alarms, interlocks, and trends were displayed in real time.

After six months of operation, on-site monitoring confirmed stable and reliable signal output—no false or missed alarms. Even during fluctuating levels and frequent process switching, the Ring-11 responded accurately and consistently.

The maintenance team reported no need for manual cleaning or recalibration, significantly reducing workload.

From a production standpoint, the improvement was evident: the previous occasional signal delays that affected pump start/stop timing were eliminated. Now, the switching is crisp and stable, allowing remote monitoring from the control room without night-shift patrols.

As one process engineer commented:

“Ring-11 runs steadily and gives us peace of mind. Since installation, we haven’t had to touch it once—it just works.”

Project Significance

This upgrade illustrates a clear trend in level measurement: transitioning from traditional mechanical tuning forks to intelligent, high-reliability point level switches.

The Ring-11’s stability, system compatibility, and ease of integration make it ideal for modern process plants. It connects seamlessly to DCS systems without extra programming or interface conversion, enabling digital transformation with minimal effort.

Moreover, its robust performance under foam, light deposits, and vibration minimizes human intervention and reduces maintenance costs. The engineering team plans to standardize Ring-11 across other plant units, achieving unified measurement standards and simplified management.

After field verification, the plant recorded noticeable improvements in signal accuracy and response speed, enhancing pump control, alarm reliability, and interlock safety—effectively eliminating previous overflow and dry-run incidents.

This replacement project was not merely an instrument swap, but a strategic step toward smarter, safer, and more efficient level measurement, offering a valuable reference for other chemical plants seeking similar upgrades.