Reliable Level Measurement Upgrades: From Magnetic Level Gauges to Radar Level Meters

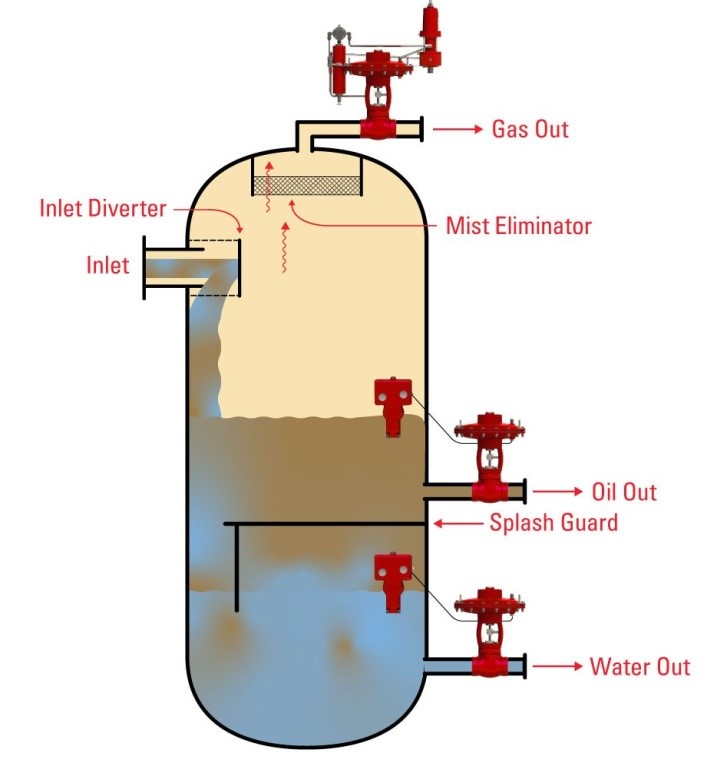

In chemical production, the reliability of level measurement and control directly affects both equipment safety and production efficiency. Level instruments are not only critical for process control but also key to ensuring smooth operation, preventing overflow, and avoiding dry running. In the past, due to technical limitations, magnetic level gauges were widely used in storage and separation tanks. However, with increasing automation levels in modern plants, traditional magnetic level gauges increasingly reveal limitations in stability, maintenance, and signal output.

Recently, a large chemical plant in the Middle East upgraded its water circulation system and gas-liquid separation tanks by replacing existing magnetic level gauges with radar level meters. The upgraded system operates stably, delivering continuous and reliable measurement data, providing a new solution for automated level monitoring.

1. Issues with Existing Equipment and Frequent Maintenance

The plant’s water circulation system supplies cooling and process water to various production units, using reclaimed water at ambient temperature and at normal or slightly negative pressure. Multiple storage and separation tanks were previously equipped with magnetic level gauges to monitor liquid levels and provide pump start/stop and alarm signals.

Over time, operators noticed several issues with magnetic level gauges:

- Float sticking and inaccurate indication.

Sediments and impurities in the reclaimed water accumulate in the float guide tube, causing the float to move poorly, leading to lagging or stuck readings. - Field readings inconsistent with actual liquid level.

During liquid surface fluctuations or micro-bubbles, floats respond poorly, resulting in deviations between local readings and DCS signals. - High maintenance frequency and labor dependency.

As mechanical devices, magnetic level gauges require regular cleaning and calibration, increasing manpower and cost. - Discontinuous signal output.

Additional components like magnetostrictive or reed switches are susceptible to vibration, temperature, and humidity, causing signal interruptions or drift.

These problems increased maintenance workload and posed risks to continuous operation. To fundamentally improve measurement stability and automation, the plant decided to upgrade its level instrumentation.

2. Technology Selection: Radar Level Meters Replacing Magnetic Gauges

During technology evaluation, the project team considered ultrasonic, hydrostatic, and radar level measurement solutions. Given the limited medium cleanliness, tank surface fluctuations, and potential temperature and pressure variations, non-contact radar level meters were chosen to replace magnetic level gauges.

The 80GHz radar level meter uses high-frequency microwave pulses. Electromagnetic signals are emitted from the antenna, reflected by the liquid surface, and received back, with level calculated based on signal travel time. Compared with magnetic gauges, radar level meters offer:

- Non-contact measurement, no mechanical wear. Unaffected by dirt, scaling, or foam.

- Low maintenance and long-term stability. No moving parts, no cleaning or recalibration required.

- Strong adaptability. Accurate in ambient, high humidity, steam, or variable temperature conditions.

- Standardized signal output. Supports 4–20mA and HART communications for easy DCS integration.

In this project, radar level meters were installed at the top flanges of water circulation and separation tanks, using existing interfaces without new openings, greatly shortening installation time.

The Jiwei PRO series 80GHz high-frequency radar level meter used in the project features PTFE fully-sealed antennas for anti-condensation and corrosion resistance. It employs Jiwei’s proprietary high-speed signal processing chip to accurately identify liquid surfaces even in the presence of turbulence or bubbles.

Its 80GHz frequency and narrow 3° beam angle allow precise focusing, avoiding false echoes from tank structures. Dynamic signal curve adaptive algorithms ensure stable measurement under alternating gas-liquid conditions or rapid level changes.

At the system level, Jiwei PRO series meters support multiple protocols (HART, Modbus) and allow easy configuration of zero, span, and output. Wide power supply range (DC 12–36V) with reverse polarity and surge protection ensures long-term stability in industrial electrical environments. Dedicated process connections ensure optimal echo in different tank types, with ±1mm accuracy, fully meeting continuous monitoring and remote control requirements.

This upgrade solved issues of float sticking, measurement errors, and frequent maintenance, while improving system automation and data reliability.

3. On-site Commissioning and Performance

After installation, the technical team powered and calibrated the system. Intelligent adaptive algorithms allow the meters to automatically detect tank height and echo characteristics, filter signals dynamically, and output reliable measurements.

Testing results:

- Clear echo waveform at ambient conditions.

- Rapid response to liquid level changes.

- Stable readings during pump-induced fluctuations.

- HART communication shows trends matching manual measurements within ±3mm.

Maintenance feedback indicated extremely high stability, with no cleaning required even with minor scaling or condensation. Integrated sealing and corrosion-resistant antennas provide excellent interference immunity, maintaining high signal-to-noise ratio in humid, vibration-prone environments. Reliability and maintenance-free operation reduce labor requirements and enable replication across other tank systems.

4. Upgrade Results and User Feedback

The project covered multiple storage and separation tanks. Post-upgrade, the system is stable, with accurate local and DCS readings and correct alarm actions. Key feedback:

- Significantly improved reliability. No drift or false alarms after six months.

- Reduced maintenance cost. No cleaning needed, less frequent inspections.

- Easy installation and short upgrade cycle. Using existing flanges, installation shortened from three days to one.

- Strong system compatibility. Standard signals integrated into existing DCS without additional modules.

The plant technical manager noted that the upgraded system not only runs more stably but also frees operators from routine maintenance, demonstrating the value of reliable instruments in long-term operation.

5. Project Significance: From Traditional to Intelligent

Magnetic level gauges have long been used in industry due to their simple structure and visual clarity. However, as automation and digitalization increase, demands have shifted from “readable” to “connectable, controllable, and maintainable.”

This Middle East chemical plant project demonstrates that Jiwei PRO series radar level meters deliver superior performance under complex conditions and, even in ambient water circulation systems, provide stable, reliable, and maintenance-free operation.

The project validates radar meters as replacements for traditional magnetic gauges, offering a replicable upgrade path. Level measurement technology in the chemical industry is evolving from mechanical to electronic, from single-point display to system connectivity, and from periodic maintenance to intelligent operation.

With ongoing radar technology iteration and cost optimization, more traditional magnetic level gauges will be replaced by high-performance radar meters, enabling safer, more efficient, and smarter process monitoring and control.