Level Measurement Innovation Accelerates with Siemens and NVIDIA

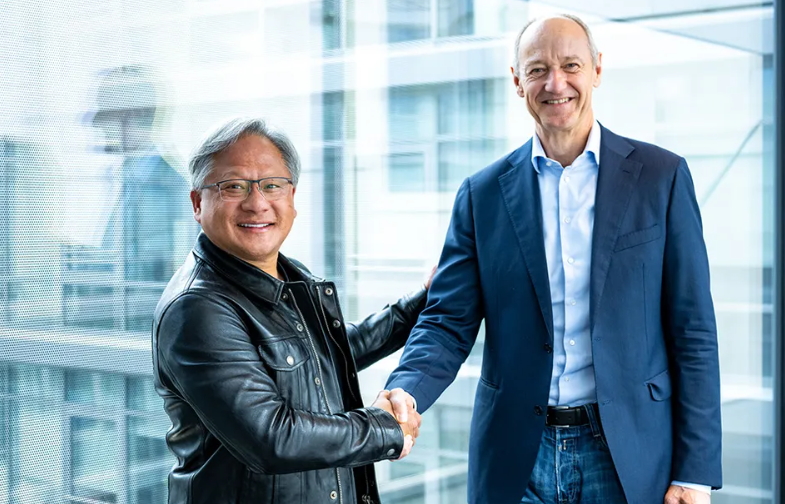

Recently, Siemens and NVIDIA announced a deepened strategic partnership aimed at advancing industrial artificial intelligence (AI) within the manufacturing sector. As leading players in the automation and measurement space, this collaboration signals transformative implications for the level measurement industry. It marks a pivotal shift toward smarter, more efficient instrumentation powered by AI and edge computing.

1. AI-Powered Level Measurement: From Sensing to Smart Decision-Making

Level measurement is a critical part of process control across industries such as chemicals, cement, food, and energy. However, it faces persistent challenges like harsh environments, signal interference, and high maintenance costs. Siemens and NVIDIA’s collaboration introduces AI-driven industrial computing platforms based on high-performance GPUs capable of real-time data processing and deep analytics.

With machine learning and advanced algorithms, future level measurement instruments will be able to:

- Automatically identify and suppress false echoes and signal noise

- Predict failures and trigger maintenance alerts before breakdowns occur

- Dynamically adapt measurement parameters for optimized device performance and longer lifespan

This evolution enables level sensors to shift from basic data acquisition tools to intelligent decision-support systems. The result: more reliable and precise monitoring of material levels in complex industrial scenarios.

2. Edge AI and Industrial IoT: Strengthening Real-Time Capabilities

One key focus of the Siemens-NVIDIA partnership is enhancing edge computing capabilities — an area of particular relevance for level measurement. Devices like radar and ultrasonic level meters are often installed in remote, dusty, or high-temperature environments where latency and connectivity are critical issues.

With the integration of NVIDIA’s AI acceleration hardware, smart level meters can process and analyze data directly on-site, reducing reliance on cloud infrastructure while improving response speed and data security. This development significantly strengthens the role of smart level sensors within the Industrial Internet of Things (IIoT), enabling:

- Real-time condition monitoring and predictive maintenance

- Seamless integration with SCADA and DCS systems

- Enhanced operational safety and energy efficiency

3. Driving New Standards and Broadening Application Scenarios

This collaboration is likely to influence the standardization of industrial AI applications, setting the groundwork for more consistent and secure deployment of AI-enabled measurement instruments. For the level measurement industry, this will support rapid adoption of AI-based solutions in extreme conditions — including high-dust silos, high-pressure reactors, and highly corrosive environments.

Moreover, we can anticipate the emergence of multi-sensor fusion technologies in level measurement — combining radar, vision systems, acoustics, and vibration analysis to create hybrid measurement solutions. This represents a breakthrough in overcoming the limitations of traditional single-mode sensing.

4. Competitive Landscape Redefined

The rise of AI-powered measurement devices will also reshape the competitive dynamics within the level measurement industry. Companies capable of integrating AI with strong R&D and domain expertise will gain a significant edge. Siemens, with its industrial legacy and access to cutting-edge GPU technology via NVIDIA, is positioned to lead this shift and set new technological benchmarks.

This change is also expected to drive innovation among emerging players and domestic brands, accelerating the development of cost-effective, intelligent level sensing solutions. The competition will evolve toward delivering not just precision, but also adaptability and smart control.

Conclusion

The strengthened alliance between Siemens and NVIDIA represents more than just a tech partnership — it signals the dawn of a new industrial AI era. For the level measurement sector, this means the beginning of a shift toward smart, autonomous, and networked instrumentation.

In the near future, level measurement devices will not merely transmit data; they will interpret it, react to it, and contribute directly to smarter process control. As the industry embraces digital transformation, AI-powered sensors and edge intelligence will become indispensable tools in achieving safer, more efficient, and greener industrial operations.

For engineers, manufacturers, and instrumentation professionals, this is an exciting turning point — one that will redefine best practices in level measurement and elevate the role of smart sensors in industrial automation.