Powerful Advances in Level Measurement: Pressure Transmitters, Flow Meters, and Transmitters

📈 1. Pressure Transmitter Market Expands, Elevating Level Measurement Precision

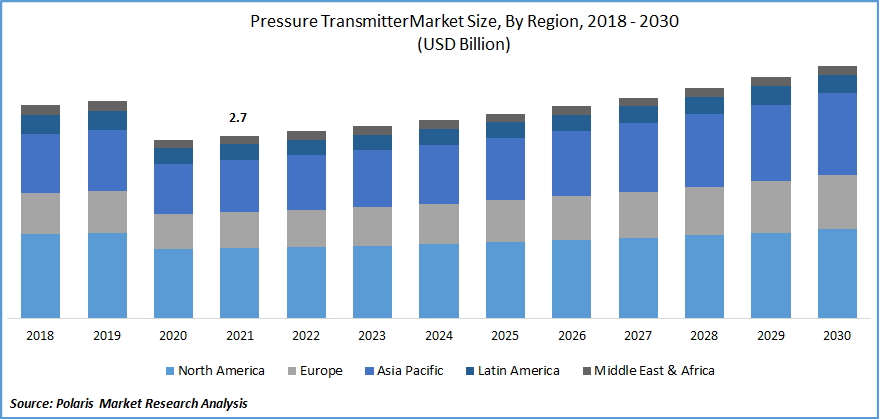

Recent market analysis projects the global pressure transmitter market will reach $3.84 billion by 2030, growing at a compound annual growth rate (CAGR) exceeding 3%. Pressure transmitters have become indispensable in liquid level measurement across various industries such as oil and gas, chemicals, water treatment, and food processing. Their core contributions include:

- Providing accurate real-time monitoring of liquid static pressure to ensure precise tank and silo level data, critical for process safety and optimization;

- Enabling integration with digital platforms and Industrial Internet of Things (IIoT) systems, facilitating remote monitoring, data logging, and predictive maintenance, which minimize unplanned downtime and maintenance costs;

- Meeting increasing demands for instruments compliant with strict industrial automation protocols, environmental regulations, and high safety standards, such as ATEX and SIL certifications.

This rapid growth reflects industry-wide recognition of the value of combining pressure and level measurement into unified, high-precision digital instruments.

🔧 2. Emerson’s New Non-Intrusive Ultrasonic Flow Meter Advances Measurement Technology

Emerson recently launched the Flexim FLUXUS/PIOX 731 ultrasonic flow meter series, designed for non-intrusive, high-accuracy flow measurement. Its modular design and advanced sensing technologies offer:

- Gas-liquid two-phase flow detection and wet gas compensation, improving accuracy in complex fluid environments;

- Robust performance under extreme process conditions including high and low temperatures, humid steam, and aggressive chemical atmospheres;

- Certifications such as ATEX, IECEx, and FM, assuring safe operation in hazardous environments.

This innovation highlights a shift in flow measurement technology towards intelligent, maintenance-friendly devices that can seamlessly integrate with level measurement instruments. Such integration supports holistic process parameter monitoring, improving overall process control and efficiency.

🏭 3. Siemens SITRANS P320 Enhances Maintenance at BASF’s Chemical Facility

Siemens SITRANS P320 pressure transmitter deployment at BASF’s chemical plant resulted in an 18% reduction in unplanned downtime, driven by:

- Compatibility with Siemens’ MindSphere cloud platform, enabling remote real-time monitoring and AI-based anomaly detection for proactive maintenance alerts;

- Ultra-low latency PROFINET communication (<2ms) ensuring fast, reliable data transfer critical for real-time control systems;

- Exceptional measurement stability and accuracy, enhancing operational reliability and safety.

This success story exemplifies the growing role of cloud integration and edge AI in advancing the capabilities of level and pressure measurement devices, supporting predictive maintenance and operational excellence.

🌍 4. European Electromagnetic Flow Meter Market Steadily Grows

The European electromagnetic flow meter market is forecasted to grow from $148 million in 2023 to $200 million by 2032, with a CAGR of 3.37%. The increasing adoption of insertion and inline electromagnetic flow meters is driven by:

- The need for IIoT-enabled smart upgrades that offer real-time monitoring, remote control, and data analytics;

- The demand for highly precise, regulation-compliant measurement solutions in wastewater, power generation, and chemical industries;

- The trend toward easy-maintenance solutions capable of handling highly conductive and corrosive fluids.

This growth trend aligns with advancements in level measurement technologies, collectively enabling comprehensive and intelligent process monitoring.

🔍 Industry Insights and Future Outlook

| Trend | Core Value |

|---|---|

| Digital Integration | Combining pressure, flow, and level measurement under IoT and cloud platforms for centralized monitoring and control. |

| Non-Intrusive Measurement | Ultrasonic and electromagnetic flow meters minimize process disruption and simplify maintenance. |

| Intelligent Operation | AI-enhanced transmitters enable predictive maintenance and reduce downtime. |

| Regulatory Compliance | Increasingly stringent global safety and environmental standards push for instrument modernization and local standard harmonization. |

✅ Recommendations for Industry Stakeholders

- Procurement: Select instruments offering IIoT connectivity, intelligent diagnostics, and high safety certification such as ATEX and SIL2 for future-proofing operations;

- Technology Adoption: Integrate cloud computing and edge AI technologies to realize real-time, multi-parameter process monitoring and predictive analytics;

- Instrument Selection: Prioritize durable, corrosion-resistant, and highly stable devices that can withstand challenging industrial environments and meet evolving regulatory demands.