Application of Vibrating Rod Level Switch in Coal Conveyor Pipes for Power Plants

I. Often Underestimated Measurement Point: Coal Drop Pipe

In bulk material conveying systems used in coal, power, and metallurgy industries, engineers often focus on level measurement in silos or storage bins, while paying less attention to the coal drop pipe. In practice, however, the coal drop pipe is one of the most prone locations for abnormal conditions, and vibrating rod level switches are widely used to provide reliable blockage detection in these critical points.

Coal drop pipes typically connect belt conveyors, screening equipment, crushers, or coal storage bins, serving as the transition channel for coal between process stages. When blockages or full-pipe conditions occur at this point, the impact is not localized but can quickly propagate through the system. Minor incidents may reduce conveying efficiency, while severe cases can cause belt slippage, equipment overload, or even emergency shutdowns. Therefore, effective monitoring of coal status within drop pipes is essential to ensure the stable operation of the conveying system.

II. What is This Measurement Technically Called?

In engineering documentation and on-site discussions, this measurement point is usually not referred to as “continuous level measurement.” More accurately, it is described as:

- Coal drop pipe level switch detection

- Blockage detection

- Full-pipe detection

- Material accumulation detection

At its core, this is a status detection problem:

Is there abnormal coal accumulation inside the pipe?

Thus, this type of application focuses on a binary signal (“yes/no,” “flow/blocked”) rather than the exact material height, which directly informs instrument selection.

III. The Real Complexity of Coal Drop Pipe Conditions

Externally, a coal drop pipe may appear to be a simple steel tube, but internal conditions are highly complex.

- Uncertain material behavior: Under normal operation, coal moves through the pipe in free fall or at high velocity, with only brief, intermittent contact with the sensor. Under abnormal conditions, coal gradually accumulates, forming stable coverage. The instrument must accurately distinguish between these two states.

- Impact and wear: Falling coal chunks repeatedly strike the pipe wall and sensor. A high proportion of large coal pieces increases mechanical stress on the instrument.

- Dust and environmental interference: Coal drop pipes have extremely high dust concentrations, often accompanied by vibration, noise, and temperature fluctuations, all of which can affect non-contact measurement methods.

- Limited maintenance accessibility: Many drop pipes are located at height, in enclosed or intersecting positions. Frequent instrument failures increase maintenance costs and safety risks.

IV. Limitations of Common Solutions

In practical projects, users have tested multiple technical approaches for blockage detection, all of which revealed significant limitations during long-term operation.

- Baffle-type or mechanical swing level switches: These rely on mechanical movement to detect material. While functional under laboratory conditions or short-term operation, in drop pipes the high impact and repeated collisions cause wear, misalignment, or jamming of moving parts. This leads to delayed response or failure, reducing sensitivity over time and increasing maintenance frequency.

- Photoelectric or ultrasonic sensors: In high-dust, turbulent environments, optical windows and ultrasonic paths are easily obstructed or scattered. Signal attenuation, false reflections, or lost echoes are common, causing false or missed alarms. These sensors depend heavily on clean, stable conditions and are often unreliable for long-term operation in typical coal conveying systems.

Overall, solutions that work under laboratory conditions or light-duty applications often fail to provide stable, reliable blockage detection under high-impact, high-dust, continuous-operation conditions of actual coal drop pipes.

V. Shift in Selection Approach

In this case study, the user gradually clarified their selection principle: do not pursue complex functions or long detection ranges; prioritize long-term reliability.

The essential requirements are:

- Can reliably detect whether the pipe is flowing freely

- Can detect persistent coal accumulation

Meeting these requirements, the project ultimately selected the Jiwei vibrating rod level switch as the blockage detection device for the coal drop pipe.

VI. Working Principle of the Vibrating Rod Level Switch

The Jiwei vibrating rod level switch is a typical contact-type level switch. When powered, the rod vibrates at a fixed frequency driven by an internal actuator.

- When the rod is in air or only briefly impacted by falling coal, its vibration remains stable, indicating no accumulation.

- When coal gradually accumulates and continuously covers the rod, vibration is dampened, causing changes in frequency and amplitude. The electronics detect this change in real time and output a stable binary signal.

This principle makes the vibrating rod level switch independent of dielectric constant and reflection signals, and unaffected by dust, making it highly suitable for coal detection applications.

VII. Installation Method and On-Site Details

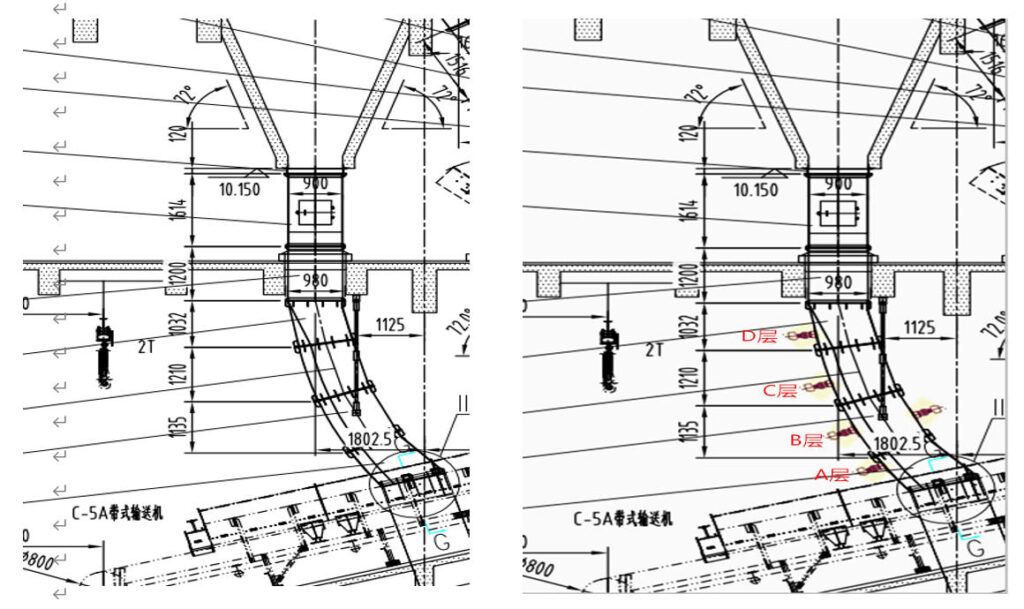

This project involved a fuel conveyor system in a power plant. The drop pipe consists of 10 mm steel plate with 25 mm three-in-one wear-resistant ceramic lining, resulting in a total effective thickness of approximately 35 mm, providing strong abrasion and impact resistance.

The vibrating rod level switch is installed on the sidewall of the drop pipe. Installation location is critical for long-term stable operation:

- Avoid the main high-speed coal impact area to reduce mechanical wear

- Ensure that in blockage or full-pipe conditions, coal covers the rod promptly for reliable detection

After on-site verification, the installation point was chosen in the downstream area prone to material accumulation, balancing impact resistance and detection sensitivity.

The rod insertion length was confirmed multiple times to ensure sensitivity to blockage while limiting mechanical stress, improving durability and operational reliability.

The output signal is connected to the PLC system for interlock control and blockage alarm, ensuring safe system operation.

VIII. Actual Customer Feedback

After a period of operation, maintenance staff reported that under normal conveying conditions, the system requires minimal intervention, with no false or unnecessary alarms. In the event of abnormal accumulation, it outputs stable and timely signals, supporting interlocks and alarm requirements.

The maintenance team noted that the system is suitable for high-impact, high-dust environments, reducing daily maintenance workload while providing reliable blockage detection when needed.

IX. Conclusion Vibrating Rod Level Switch

Coal drop pipe level monitoring is fundamentally a safety- and stability-oriented engineering task.

In this application, complex algorithms or high-resolution measurement are not core requirements. What matters most is an accurate understanding of the working conditions and ensuring the long-term reliability of the instrument.

The Jiwei vibrating rod level switch, based on a mature vibration detection principle, is simple in structure, resistant to interference, and capable of operating reliably in high-impact, high-dust environments. It provides stable, repeatable detection for blockage conditions and is practical and sustainable in engineering applications. Vibrating Rod Level Switch

In coal conveying systems, some measurement points may seem insignificant, but failure can trigger chain reactions, potentially affecting the entire system. In such applications, reliability is the most critical and irreplaceable factor. Vibrating Rod Level Switch