Radar Level Meters and Level Switches Empower European Clean Energy Plant

Recently, Shenzhen Jiwei Automations Ltd., leveraging its expertise in liquid level measurement and project experience, successfully won the bid for the Helios BioEnergy Project in France. The project deploys multiple Jiwei instruments, including PRO series radar level meters and Ring-11 fork level switches, across key process units for methanol recovery, gas-liquid separation, and dry-run protection, providing reliable support for automation and safe operation in European clean energy production.

1. Project Background: A European Clean Energy Benchmark

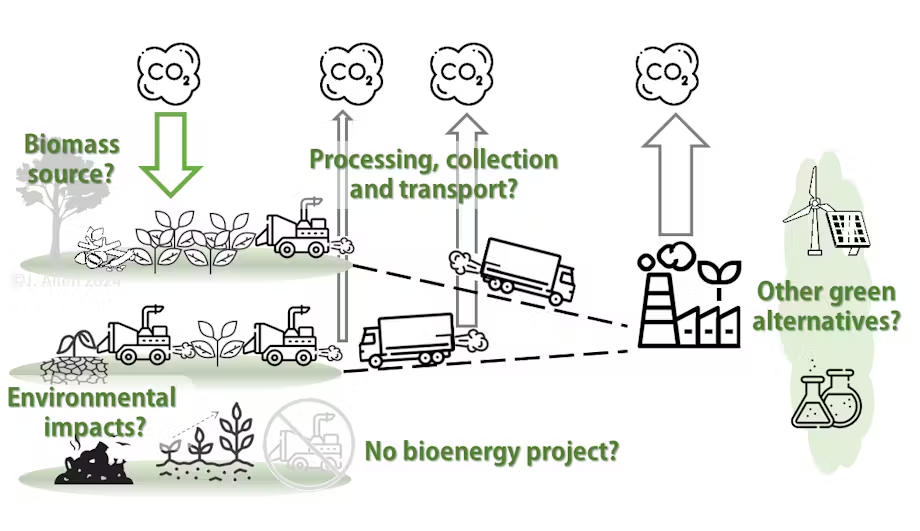

Located in northern France, the Helios BioEnergy Project is a comprehensive green energy facility jointly invested by European energy companies. Using biogas as the feedstock, the project employs multi-stage separation, absorption, and distillation to produce high-purity biomethane and methanol for power generation and chemical applications.

Upon completion, the plant will process over 200,000 tons of organic waste annually, producing around 150 million cubic meters of renewable energy, reducing CO₂ emissions by approximately 250,000 tons per year. This supports France’s 2050 carbon neutrality target and serves as a key demonstration of Europe’s clean energy transition.

In this system, liquid level monitoring is critical. Whether controlling tower liquid levels, detecting liquid interfaces in separators, or preventing overflow and dry-run conditions, instrumentation directly affects process stability and equipment safety. The project’s process media are complex, high-temperature, and high-pressure, demanding instruments with high reliability, corrosion resistance, and stable long-term performance.

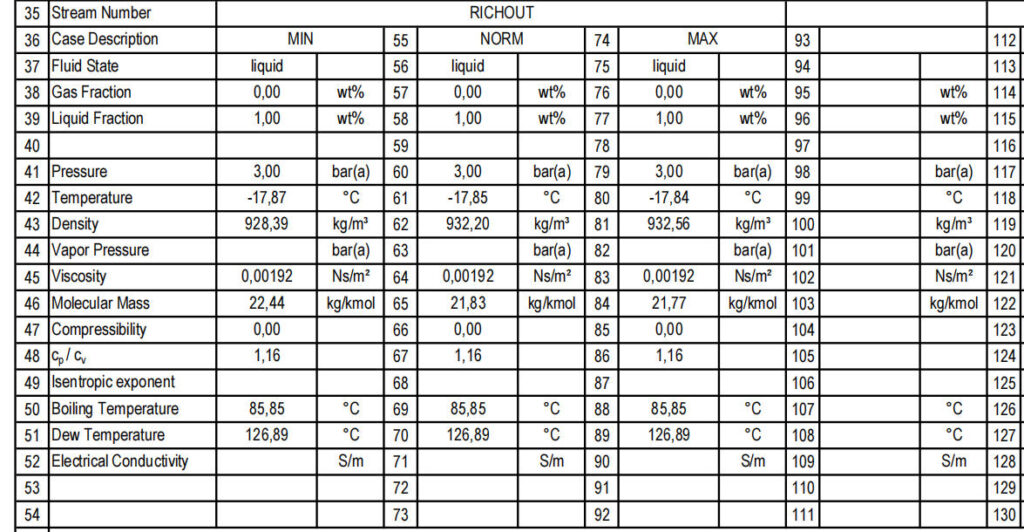

2. Process Challenges: High Temperature, High Pressure, Multi-Phase

Key media include methanol, water, CO₂, methane, hydrogen, H₂S, and SO₂, featuring multi-phase flow and high corrosion. Some equipment operates at 150°C and up to 21 bar.

- Gas-liquid two-phase flow in absorption and distillation towers with frequent liquid level fluctuations;

- Rapid liquid level changes in methanol collectors and condensation separation systems;

- Liquid-liquid stratification (methanol/water/organic residue) in multi-phase separators.

Traditional instruments face significant challenges under these conditions. Some imported devices experienced signal drift and false alarms during early commissioning. Consequently, the client required instruments with EX explosion-proof certification, SIL safety level, PN100 pressure rating, IP65+ protection, and complete FAT test reports.

3. Jiwei Solution: Reliable Precision Measurement

Jiwei provided a combined solution: PRO series radar level meters + Ring-11 fork level switches, for continuous monitoring and limit protection.

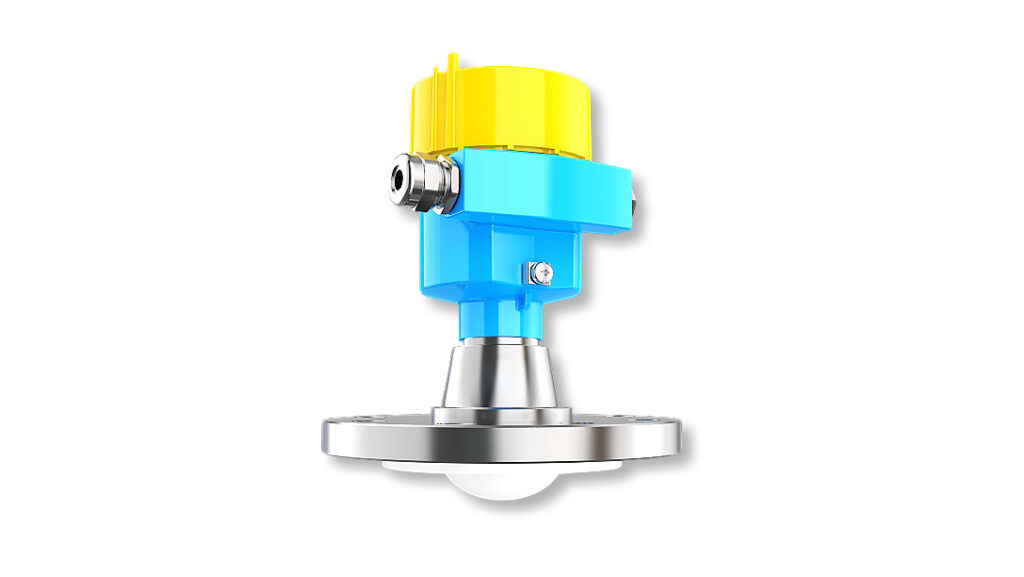

(1) PRO Series Radar Level Meters – High-Precision Monitoring

- Measurement technology: 80GHz FMCW radar with strong anti-interference capability

- Range & accuracy: 0–150 m, ±1mm accuracy

- Output: 4–20mA + HART, compatible with DCS systems

- Remote setup: Innovative Bluetooth mini-app remote configuration, China’s first

- Software: Self-developed, regularly updated

- Materials & design: PTFE radar antenna, corrosion-resistant and high-temperature durable

Installed in absorption towers (T-101), distillation towers (T-401), methanol collectors (V-407), and multi-phase separators (V-208), the radar meters delivered clear, stable readings with deviations <1mm even under foam and vapor interference.

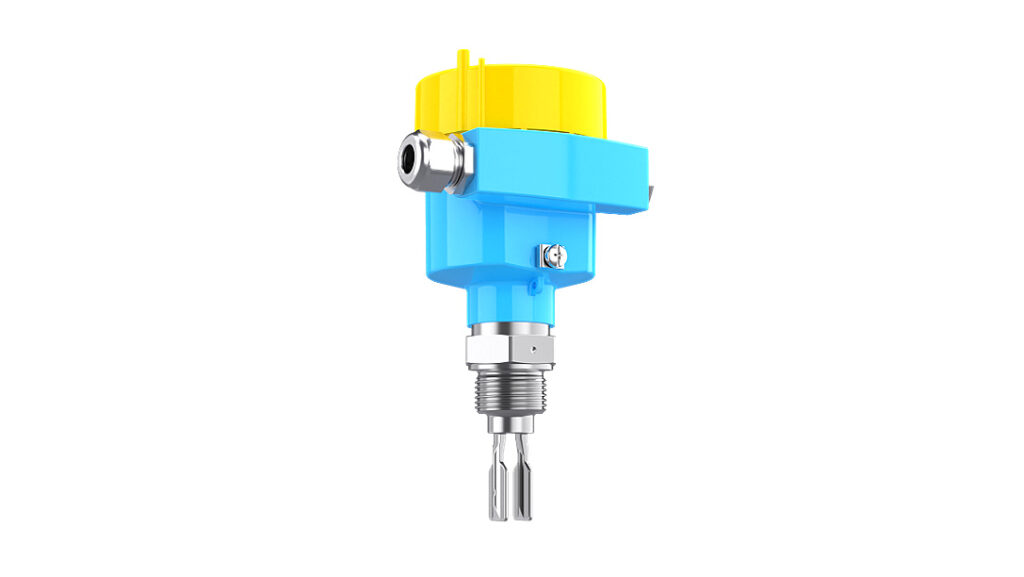

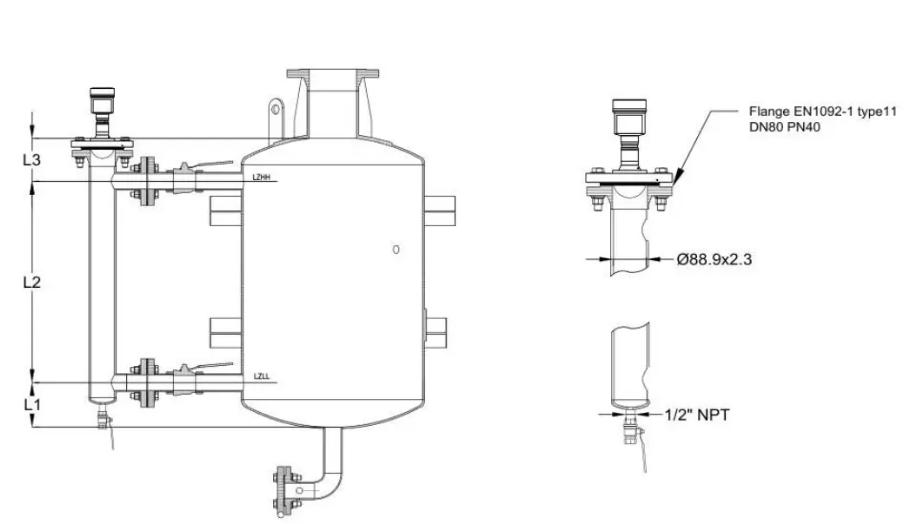

(2) Ring-11 Fork Level Switch – Safety Interlock Guardian

- Principle: Piezo-driven vibrating fork detects liquid level via frequency change

- Applicable media: Density ≥0.5 g/cm³, including methanol, condensate, gas-liquid mixtures

- Explosion-proof: Ex ia IIC T6 Ga/Gb intrinsic safety design

- Pressure & temperature: PN25–PN100, -50~+400°C

- Output: NAMUR NE43, compatible with European DCS

- Safety: Certified with EX, SIL, EAC, 3C, CE, RoHS, REACH; suitable for SIS

Installed at condensate separators, reflux tanks, and overflow alarms, Ring-11 switches ensure rapid, accurate response, preventing pump dry-run or overflow incidents.

4. Project Execution: High Standards & Local Support

A dedicated Jiwei project team managed every phase under ISO 9001 quality management system. Instruments underwent factory calibration, seal testing, and FAT verification with real-time video reporting for European clients. Technical representatives confirmed the professional manufacturing process and complete documentation.

Delivery included:

- Datasheets & model selection tables

- Wiring & process connection diagrams

- FAT reports, SIL reports, safety manuals, material & pressure certificates

- Installation & operation manuals (IOM)

Post-delivery, Jiwei engineers provided remote DCS configuration support and parameter setup guidance.

5. Customer Feedback & Project Outcomes

After commissioning, the Helios operations team praised the instruments: radar meters maintained stable readings under high humidity, temperature, and foam; Ring-11 switches responded accurately in multi-phase and gas-liquid conditions.

The project achieved:

- Reduced manual intervention

- Extended maintenance intervals

- Stable, reliable operation

- Full recognition from the owner and EPC contractor, making Jiwei a recommended supplier for future projects

6. Conclusion

The Helios project demonstrates Jiwei Automations’ capability in European clean energy applications and showcases Chinese instrument reliability in high-end international markets. Jiwei continues to focus on liquid and point level measurement, expanding ATEX, IECEx, and SIL certifications to provide reliable, intelligent, and safe process measurement solutions worldwide.

About Jiwei Automations

China’s leading instrumentation manufacturer, products perfectly replace VEGA and meet international top-tier standards.

Shenzhen Jiwei Automations Ltd. specializes in radar level meters, fork level switches, rotary paddle switches, and vibrating rod switches. Products serve chemical, energy, environmental, food, pharmaceutical, metallurgical, and water treatment industries. Jiwei owns multiple invention patents, utility model patents, and software copyrights, covering core sensing, signal processing, and instrument design.

Jiwei emphasizes reliability as the core, with full ERP & MES traceable production. Products hold EX, SIL, EAC, 3C, CE, RoHS, and REACH certifications, compliant with IEC and EN standards.

Jiwei’s instruments are exported to Germany, Russia, Italy, Turkey, India, Korea, and Southeast Asia, performing reliably in major energy and chemical projects. Moving forward, Jiwei continues to optimize product performance and international certifications, supporting safer, smarter, and more efficient industrial processes globally.