Level and Overfill Protection Solutions for Paper Industry Storage Tanks

In chemical and paper production, the level control of chemical additives directly affects product quality, process stability, and equipment safety. Common additives include hydrogen peroxide, alkalis, acids, and fillers, which are typically stored in stainless steel or glass fiber reinforced plastic (FRP) tanks. Due to their corrosive and volatile nature, liquid level monitoring imposes higher requirements on instrument corrosion resistance and measurement stability.

To meet these application requirements, Jiwei Automations offers a comprehensive solution combining JWrada® radar level meters and Ring-11 vibrating level switches. The radar meter provides continuous level measurement, while the Ring-11 switch ensures overfill and pump dry-run protection. Together, they guarantee safe and stable operation of chemical and paper storage tanks.

Operating Conditions and Measurement Challenges

Chemical additive storage tanks in the paper and chemical industries are mostly closed or semi-closed, with typical process temperatures ranging from +10 °C to +95 °C and near-atmospheric pressure. Although the pressure is low, the stored media are often corrosive and may emit gases or vapors, leading to signal attenuation or probe corrosion.

For example, sodium hydroxide, hydrogen peroxide, and sulfuric acid release gases during storage, which interfere with conventional ultrasonic or capacitive level sensors. Contact probes are prone to corrosion or fouling, resulting in unstable measurement. Therefore, non-contact radar level meters and vibration principle level switches are ideal choices for reliable operation in highly corrosive and high-vapor environments.

Continuous Level Measurement with JWrada® Radar Level Meter

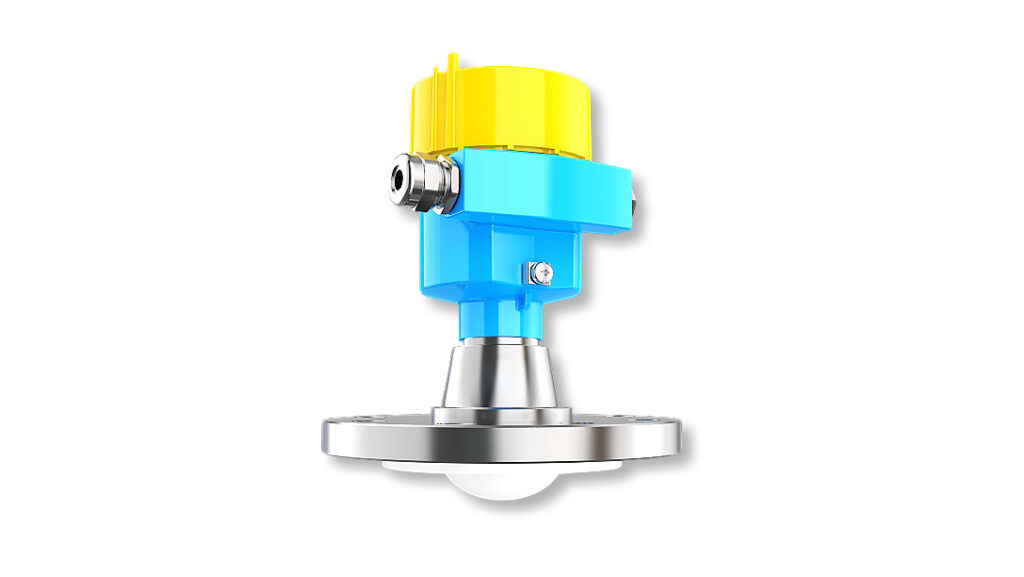

The Jiwei JWrada® radar level meter uses advanced high-frequency microwave non-contact measurement technology to provide stable level detection even in environments with vapor or corrosive media. Its chemically resistant antenna system is suitable for additive storage tanks commonly used in the paper and chemical industries.

Working Principle

The radar meter emits high-frequency electromagnetic waves toward the liquid surface and calculates the level based on the time delay of the returned echo. Radar signals are unaffected by temperature, vapor, or dielectric constant variations, ensuring continuous and accurate measurement even in dynamic or complex tank conditions.

Key Advantages

- Non-contact, maintenance-free, corrosion-resistant: The antenna does not contact the liquid, preventing fouling and chemical corrosion.

- High chemical resistance: PTFE- or PEEK-encapsulated antenna suitable for acids, alkalis, and oxidizing liquids.

- Resistant to vapor and foam: Signals penetrate vapor or light foam, ensuring stable data.

- Strong adaptability: Compatible with metal, FRP, or plastic tanks without frequent recalibration.

Performance Parameters

- Measuring range: up to 150 m

- Process temperature: -40 °C to +220 °C

- Process pressure: -0.1 to 4.0 MPa

- Measurement accuracy: ±1 mm, zero blind zone

With intelligent echo analysis and dynamic filtering algorithms, the JWrada® radar level meter provides clear level curves even under vapor or agitation conditions, supporting reliable tank management.

Overfill and Dry-Run Protection with Ring-11 Vibrating Level Switch

To ensure that chemical and paper factory tanks do not overflow or pumps run dry during filling or discharge, Jiwei’s Ring-11 vibrating level switch provides independent safety protection.

Working Principle

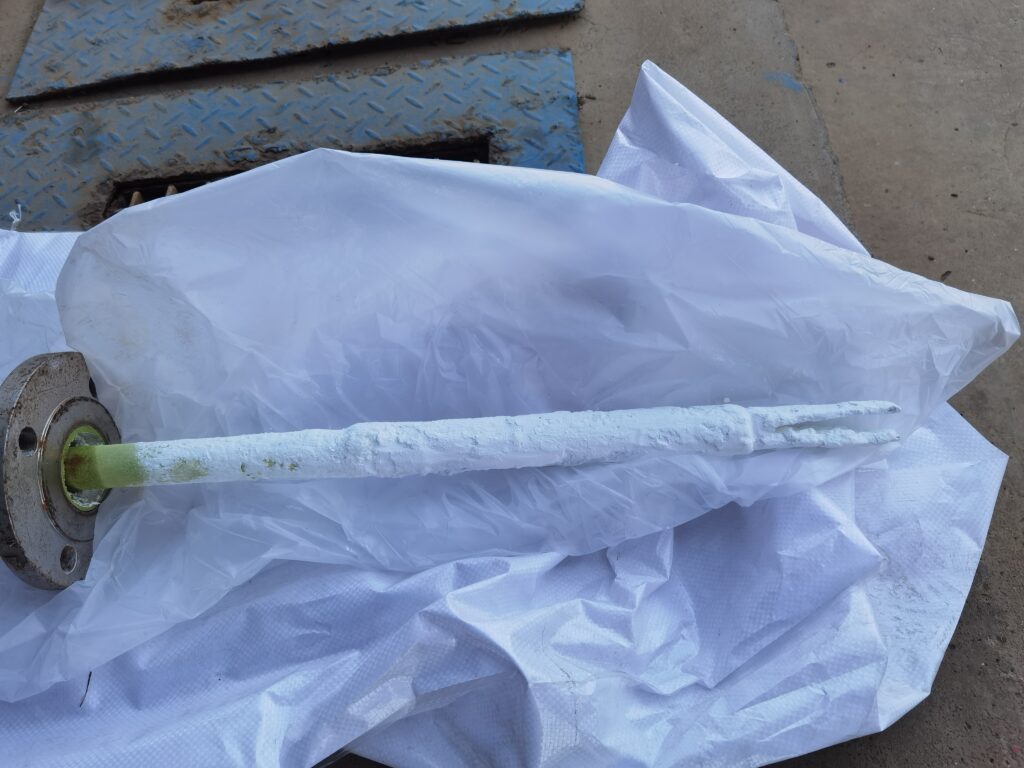

The Ring-11 probe contains a piezoelectrically driven fork that vibrates at a specific frequency. When the liquid touches the fork, the vibration frequency changes, and the controller outputs a switch action, triggering pump stop, valve closure, or an alarm to prevent overflow and equipment damage.

Key Advantages

- Independent and reliable detection: Unaffected by liquid conductivity, viscosity, or density.

- Corrosion-resistant construction: Wetted parts made of stainless steel or chemically resistant materials, suitable for acids, alkalis, and solvents.

- High sensitivity: Detects even low-density liquids for accurate switching.

- Easy installation: Compact, can be installed horizontally or vertically, with low maintenance.

- Wide application: Suitable for overfill protection, dry-run prevention, leakage detection, and safety interlocking.

Performance Parameters

- Process temperature: -50 °C to +400 °C

- Process pressure: -1 to +64 bar

- Output options: SPST, DPDT relay, PNP/NPN transistor, or NAMUR interface

- Protection grade: IP67, suitable for outdoor chemical environments

The gas-tight leadthrough structure effectively prevents vapor leakage, meeting the stringent safety and environmental requirements of chemical and paper industries.

Integrated Level Control Solution

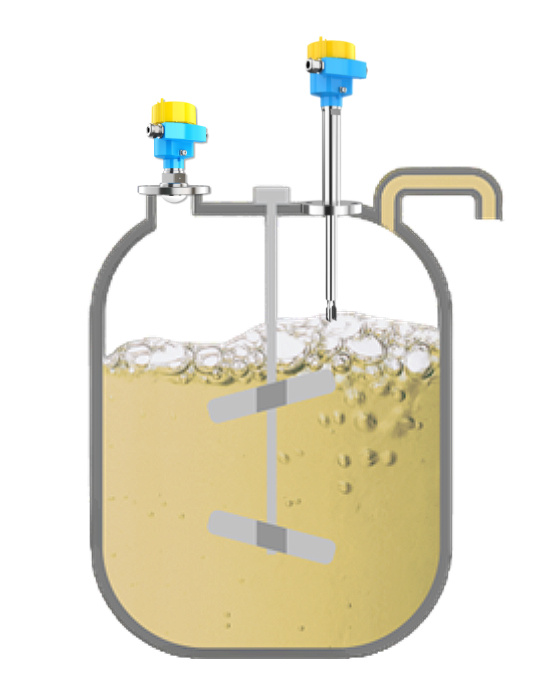

Combining the JWrada® radar level meter with the Ring-11 vibrating level switch provides an integrated solution for tank level monitoring and safety protection. JWrada® offers continuous real-time level and volume monitoring, transmitting data directly to the automation system for precise tank management and production optimization. The Ring-11 switch acts as an independent overfill and dry-run protection layer, immediately triggering alarms or cutting off supply when liquid levels exceed safe limits.

Integrated Advantages

- Continuous monitoring: JWrada® provides accurate real-time level data for automatic control.

- Independent overfill protection: Ring-11 ensures immediate shutdown during abnormal filling.

- Smart connectivity: Seamless integration with PLC or DCS, supporting analog and digital communication.

- Low maintenance, high reliability: Non-contact and vibration principles eliminate mechanical wear, extending service life.

This combined solution has been widely applied in paper, chemical, pharmaceutical, and environmental industries, effectively preventing chemical spills, improving operational safety, and enhancing process efficiency.

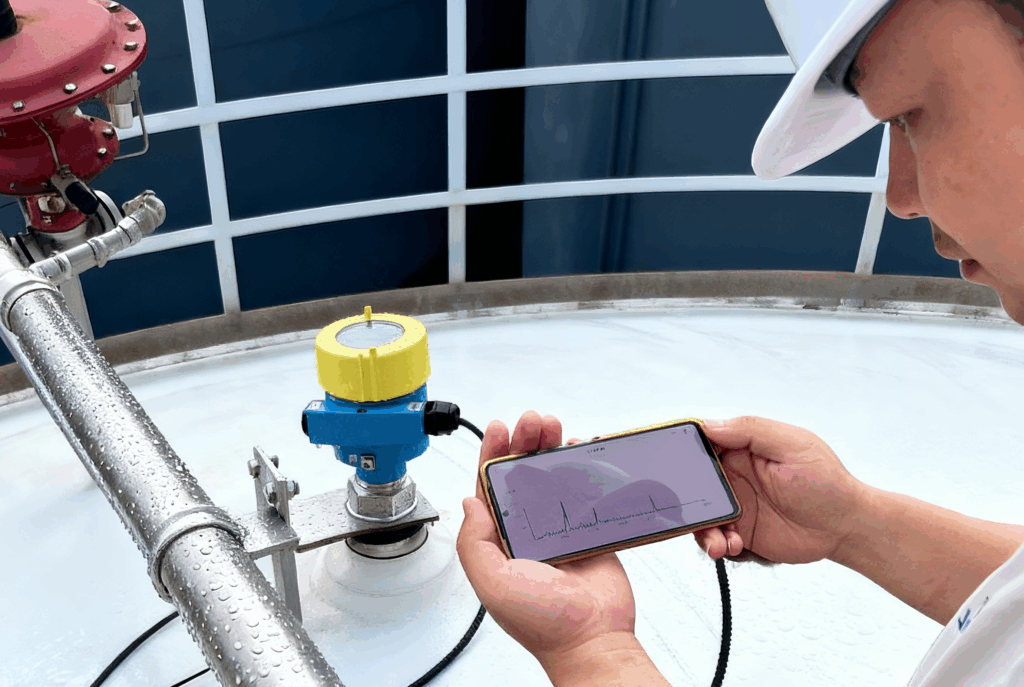

Case Study: Chemical Additive Storage in a Ningbo Paper Mill

At a Ningbo paper mill, monitoring the level of sodium hydroxide and hydrogen peroxide in storage tanks has always been a critical production task. Previously used ultrasonic level sensors frequently failed due to high vapor concentrations and light foam in the tanks, while temperature fluctuations and chemical corrosion caused measurement instability, increased maintenance costs, and posed overflow and pump dry-run risks.

Solution Provided by Jiwei Automations

- JWrada® Radar Level Meter: Non-contact microwave radar provides continuous level measurement, unaffected by vapor, foam, or temperature fluctuations, giving operators real-time data for tank utilization optimization and precise production planning.

- Ring-11 Vibrating Level Switch: Provides overfill and pump dry-run protection. Once the liquid reaches the set point, the switch automatically triggers to stop the pump or activate an alarm, forming an independent safety interlock.

After implementation, level measurement stability significantly improved, tank utilization increased by approximately 15%, maintenance frequency decreased by over 60%, and no overflow incidents occurred. The radar meter’s non-contact measurement and Ring-11’s corrosion-resistant design extended equipment lifespan, reduced operational costs, and enhanced tank operation safety and process reliability, providing an efficient and sustainable solution for chemical additive management at the Ningbo paper mill.

Conclusion

In chemical and paper storage tank management, safety and reliability are paramount. Jiwei JWrada® radar level meters provide non-contact continuous measurement unaffected by vapor or corrosive media, while Ring-11 vibrating level switches establish an independent protective system to prevent overfill and pump dry-run.

Together, they form an efficient, safe, and low-maintenance level control system, offering chemical and paper industries a cost-effective solution that ensures production safety and environmental protection.