Reliable Level Measurement for Buffer Tanks with Radar Level Meter and Vibrating Level Switch

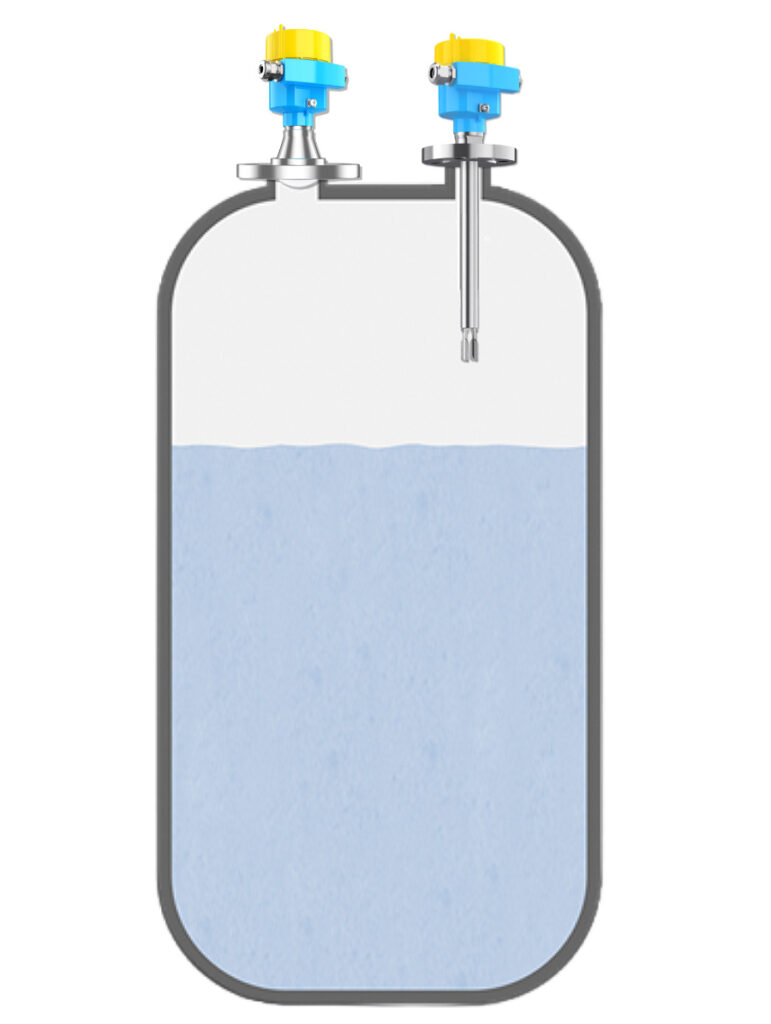

In industrial production, buffer tanks and storage tanks are crucial to ensure continuous production and stable material supply. To maintain smooth processes, operators must have real-time awareness of the liquid level inside buffer tanks, achieving both continuous level measurement and point level detection. Jiwei Automations provides a comprehensive solution with radar level meters and limit switches, combining high-precision measurement technology, high-temperature and high-pressure resistance, and intelligent functionality, perfectly meeting the complex operating conditions of industrial sites.

Key Challenges in Buffer Tank Level Measurement

Buffer tanks often contain complex and variable media, which may involve the following issues:

- Frequent medium changes: Differences in density, viscosity, and conductivity between batches can affect the stability of traditional instruments.

- Temperature and pressure fluctuations: High or low temperatures or pressure variations can lead to sensor drift, affecting measurement accuracy.

- High safety and protection requirements: Uncontrolled liquid levels may cause overflows or dry-run conditions, threatening production safety and equipment lifespan.

In this context, using high-performance radar level meters in combination with limit level switches enables both continuous level measurement and overflow/dry-run protection, ensuring production safety, efficiency, and reliability.

Key Specifications:

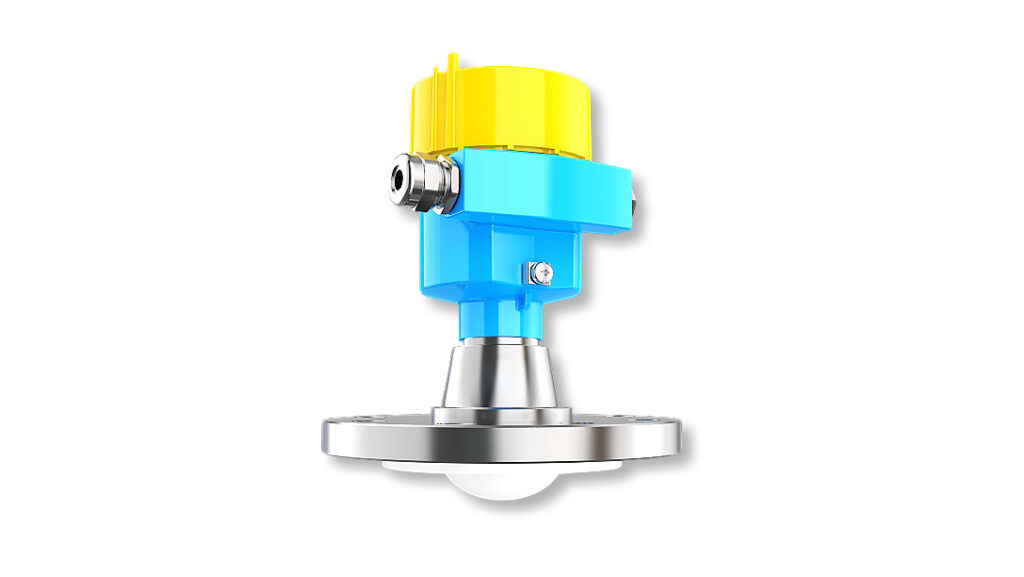

- Measurement range: 0–150 m (0–60 m optional)

- Output signal: 4–20 mA / HART / Modbus

- Process temperature: -40℃ ~ +220℃

- Process pressure: -1~40 bar (-1~25 bar optional)

- Antenna material: PTFE / 316L stainless steel

- Protection rating: IP68

- Installation: Threaded / Flanged

- Commissioning: Supports Bluetooth and remote HART control, integrated with the “Jiwei Smart Control” app — the only nationwide app that allows full remote operation and visualization, avoiding complex on-site procedures. Bluetooth function optional.

- Software system: Fully self-developed software algorithm platform, ensuring continuous optimization and iteration of signal processing. The proprietary algorithm guarantees leading-level measurement accuracy and stability, even under changing media, temperature fluctuations, or dusty environments.

Product Advantages:

- Non-contact measurement: Prevents wear and medium adhesion, reduces maintenance, and ensures long-term stable operation without frequent cleaning or probe replacement.

- Smart algorithm: Proprietary algorithm platform continuously optimizes signal processing for media changes, temperature and pressure fluctuations, and complex conditions, ensuring accurate and reliable measurement.

- High accuracy and reliability: ±1 mm measurement precision; maintains continuous and stable level monitoring even in high-temperature, high-pressure, or dusty environments.

- Flexible installation: Compact design suitable for space-limited buffer tanks, supports threaded or flanged mounting, replacing traditional instruments without modifying existing installation points.

- Remote commissioning and monitoring: Supports Bluetooth and remote HART; the app enables full control, parameter setting, echo monitoring, and fault diagnosis visualization, greatly improving commissioning efficiency.

- Durable and safe: High protection (IP68) and corrosion-resistant materials (PTFE/316L stainless steel) ensure suitability for harsh conditions, safeguarding equipment and production continuity.

- Energy-saving and cost-effective: Non-contact design, low maintenance, and intelligent remote operation reduce operational and maintenance costs while improving production efficiency.

Key Specifications:

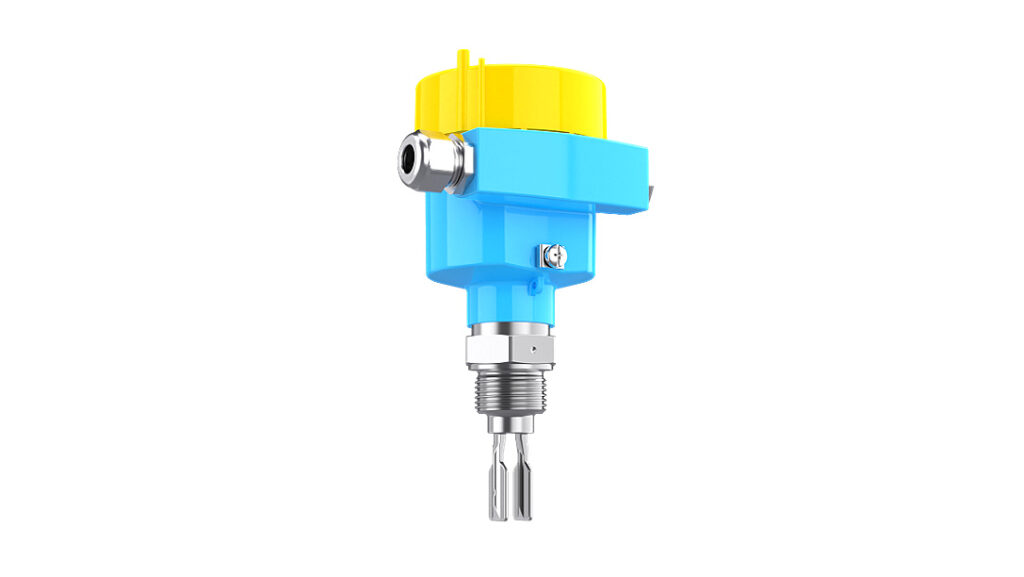

- Point detection: Overflow and dry-run protection

- Operating temperature: -40℃ ~ +400℃, industry-leading

- Operating pressure: -1~64 bar

- Material: 316L stainless steel, high-corrosion-resistant alloy, Hastelloy

- Certification: EAC, SIL, CE, 3C

- Patents: Multiple domestic and international invention patents

- Installation: Threaded or flanged

Product Advantages:

- Leading high-temperature technology: Operates reliably in media up to 400℃, far exceeding standard market products. Maintains sensitive response and long-term stability in high-temperature steam, hot liquids, or chemical media, avoiding measurement drift or failure due to temperature. This technology leads the Chinese market, providing reliable solutions for high-temperature applications.

- Sealed insulated sleeve: Designed for high-temperature and high-pressure conditions, ensuring system sealing and electrical insulation. Made with proprietary materials, it is corrosion-resistant, heat-resistant, and pressure-resistant, providing stable operation and reducing equipment failure risks.

- Safety and reliability: SIL-certified, offering reliable protection against overflow and dry-run scenarios, preventing accidents and extending equipment life while minimizing production loss.

- Technological innovation: Multiple patents combined with proprietary high-frequency vibration signal tuning deliver industry-leading sensitivity and anti-interference performance. Accurate and reliable point detection is maintained even under complex media, dust interference, or flow disturbances.

- Easy on-site installation: Standard threaded or flanged interfaces allow quick mounting and commissioning, compact design suits space-limited tanks, and Bluetooth/remote HART functionality enhances installation efficiency and real-time signal visualization.

Application Value of Jiwei Buffer Tank Level Solution

The solution ensures production safety by preventing overflow or dry-run conditions. Real-time level monitoring combined with point-level alarms optimizes material replenishment and discharge processes, improving production efficiency. Non-contact radar measurement and high-temperature, corrosion-resistant vibrating limit switches reduce maintenance frequency and cost. Continuous level data and point signals support statistical analysis, production optimization, and quality control, facilitating digital factory management. Certified by EAC and SIL, with multiple invention patents, the solution guarantees reliability and technical leadership.

Technical Highlights:

- Continuous level measurement and point detection dual protection for production safety and operational stability.

- Radar level meter supports Bluetooth and remote HART for easy installation and maintenance.

- Compact, lightweight radar meter body (~1.5 kg) for easier handling than comparable products.

- Vibrating limit switch withstands high temperature and pressure, with rapid response and high precision.

- Proprietary algorithm platform ensures all products leave the factory with the latest optimized software, guaranteeing stable and reliable measurement performance.

Conclusion

Jiwei Automations’ buffer tank level measurement solution, combining JWrada® radar level meters and high-performance vibrating limit switches, achieves continuous measurement, point detection, safety protection, and intelligent remote commissioning. Suitable for chemical, pharmaceutical, food, or metallurgical industries, it ensures stable, reliable, and safe liquid level monitoring.

With proprietary technology, industry-leading high-temperature capability, international certifications, and multiple patents, Jiwei’s buffer tank solution is a market-leading choice for advanced industrial level measurement both in China and internationally.