Reliable Oil Tank Level Monitoring in Wind Turbine Gearboxes

Industry Background

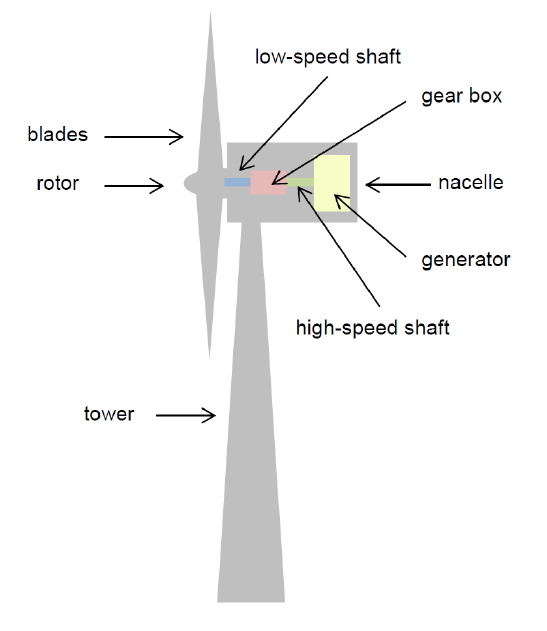

In modern wind turbines, the gearbox is the critical component that transfers wind energy from the rotor to the generator. Its operating condition directly affects the turbine’s power generation efficiency and service life. Installed at the top of the nacelle, the gearbox operates under harsh conditions — high temperature, constant vibration, and large temperature fluctuations. These factors make a reliable lubrication system essential. Insufficient lubrication can lead to bearing damage, gear wear, or even catastrophic gearbox failure, resulting in costly downtime.

To ensure stable and safe turbine operation, the gearbox oil tank must be continuously monitored for oil level. Accurate level detection is essential for dry-run protection, overfill prevention, and automatic pump control. However, traditional float or capacitive level switches often fail in high-vibration or wide-temperature environments. As a result, vibrating level switches have become the preferred solution among wind turbine manufacturers for their reliability and low maintenance.

Project Overview

This project was implemented in an onshore wind farm located along China’s eastern coast, where the installed turbines are 3.6 MW direct-drive models. Each gearbox oil tank holds approximately 120 liters of lubricant, operating between -10 °C and +80 °C. The nacelle is subject to extreme environmental variations — daily temperature differences exceeding 25 °C and strong vibration from the rotor.

The customer initially used a compact imported vibrating fork level switch but faced frequent false triggering under vibration. Maintenance costs were high, and spare parts were expensive. After on-site evaluation and performance testing, the customer selected Jiwei Automations’ Ring-21 Mini Vibrating Fork Level Switch as a reliable, compact, and cost-effective alternative.

Application Challenges

The monitoring system needed to achieve dry-run protection and overfill control for gearbox lubrication oil.

Operating parameters:

| Parameter | Value |

|---|---|

| Measuring range | 0–1 m |

| Process temperature | -10 to +80 °C |

| Process pressure | 0 bar (atmospheric) |

| Medium | Gear lubrication oil |

| Environment | Strong vibration, large temperature variations, limited installation space |

Key challenges included:

- Extremely limited nacelle space, requiring a compact-level switch design.

- Vibration interference, which can cause unstable switching signals.

- Frequent temperature fluctuations, potentially leading to false triggering.

- The low dielectric constant of lubricating oil, making capacitive or admittance-type switches unsuitable.

Jiwei Solution: Ring-21 Mini Vibrating Fork Level Switch

To address these challenges, Jiwei Automations provided the Ring-21 Mini Vibrating Fork Level Switch, purpose-built for compact installations and reliable performance in oil-based media.

Key Features

Compact Design

The Ring-21 features an ultra-short fork (38 mm) and a small M20 threaded housing, allowing easy installation in confined gearbox oil tanks without structural modification or additional brackets.

Superior Vibration Resistance

A robust mechanical structure and optimized resonant frequency design ensure stable output even under vibration acceleration exceeding 5 g — ideal for nacelle environments.

Media Independence

The switch operates reliably regardless of oil viscosity, density, or dielectric constant, making it suitable for both synthetic and mineral lubrication oils.

Dry-Run Protection

When oil levels drop below the setpoint, Ring-21 immediately outputs a switching signal to stop the oil pump, effectively preventing dry running and gearbox wear.

Easy Commissioning

Factory pre-calibration eliminates the need for field adjustment or medium calibration, simplifying installation and reducing maintenance costs.

Working Principle

The Ring-21 Vibrating Level Switch uses a piezoelectric crystal to excite the fork into resonance. When the fork contacts liquid, the resonant frequency decreases due to damping effects. The integrated electronic circuit detects this frequency change and sends a corresponding switch signal.

Unlike capacitive sensors, Ring-21 is unaffected by the electrical properties of the liquid, ensuring stable operation even in low-conductivity oils or foaming conditions.

Field Installation and Performance

In the wind turbine gearbox oil tank level monitoring project, Jiwei’s Ring-21 mini tuning fork level switch was selected as the key component for dry-run protection and overflow control. Due to the limited installation space inside the gearbox oil tank, traditional tuning fork or capacitive level switches were difficult to mount. Therefore, engineers chose the compactly designed Ring-21 model. The product was directly installed on the side wall of the oil tank with an M20 threaded connection, and the fork length was only 38 mm, perfectly fitting the confined space without affecting the internal layout of the gearbox. No additional brackets or protective covers were required.

In the control system, the Ring-21 adopts an SPST relay output signal, which is connected through the control cabinet to the safety input port of the PLC and linked with the start-stop logic of the oil pump. When the oil level drops below the set point, the PLC receives the signal and automatically stops the oil pump to prevent dry-run; when the oil level rises to a safe height, the switch resets automatically to enable oil replenishment. This interlocking mechanism allows the lubrication system of the wind turbine to operate under fully automatic protection without manual intervention, effectively preventing gear wear and overheating caused by insufficient lubrication.

During installation and commissioning, Jiwei’s technical team conducted real-time monitoring of the liquid level signal through the PLC interface. The test results showed that the Ring-21 had a response time of less than 0.5 seconds, with high sensitivity and repeatability. Throughout the entire test, there were no false triggers or signal fluctuations. Thanks to its highly vibration-resistant mechanical design and stable resonant frequency control technology, the switch maintained stable signal output even when the wind turbine was operating under vibration acceleration above 5g, without any malfunction.

In addition, the Ring-21 features a fully sealed stainless steel probe structure, providing excellent resistance to oil contamination and corrosion. Even under long-term exposure to high-temperature oil mist and strong mechanical vibration, the probe surface remains free of oil buildup or fouling, ensuring long-term maintenance-free operation. After extended field operation, the Ring-21 has demonstrated outstanding stability and reliability in the gearbox oil tank, delivering an efficient and safe liquid level protection solution for the entire lubrication system.

Customer Feedback and Results

After six months of continuous operation — exceeding 4,000 working hours — the system demonstrated outstanding reliability:

- Stable level detection without false alarms

- Maintenance-free design reduced inspection frequency

- Quick installation (less than one hour retrofit time)

- Performance comparable to imported products but at 30% lower cost

The wind farm operator reported zero lubrication-related dry-run incidents since installation, confirming that Jiwei Ring-21 provides a dependable and cost-effective level protection solution for wind turbine gearboxes.

Extended Applications

Beyond wind turbine lubrication systems, the Ring-21 Mini Vibrating Fork Level Switch is ideal for:

- Hydraulic station oil tank monitoring

- Machinery lubrication systems

- Air compressor oil level detection

- Chemical dosing tank overfill protection

- Auxiliary liquid monitoring in pharmaceutical and food equipment

Its versatility, compact structure, and high stability make Ring-21 a perfect replacement for imported vibrating level switches across multiple industries.

Conclusion

In wind energy applications where reliability is critical, any level detection failure can lead to severe maintenance costs and production losses. With its compact design, high vibration resistance, and reliable dry-run protection, Jiwei Ring-21 Mini Vibrating Fork Level Switch delivers a robust solution for gearbox oil tank monitoring.

As the renewable energy sector continues to expand, Jiwei Automations proves that Chinese high-end instrumentation can match international performance standards — providing innovative, reliable, and affordable level measurement solutions for global industrial applications.