Need Accurate PEM Level Measurement? JWrada® Radar Level Meter Delivers!

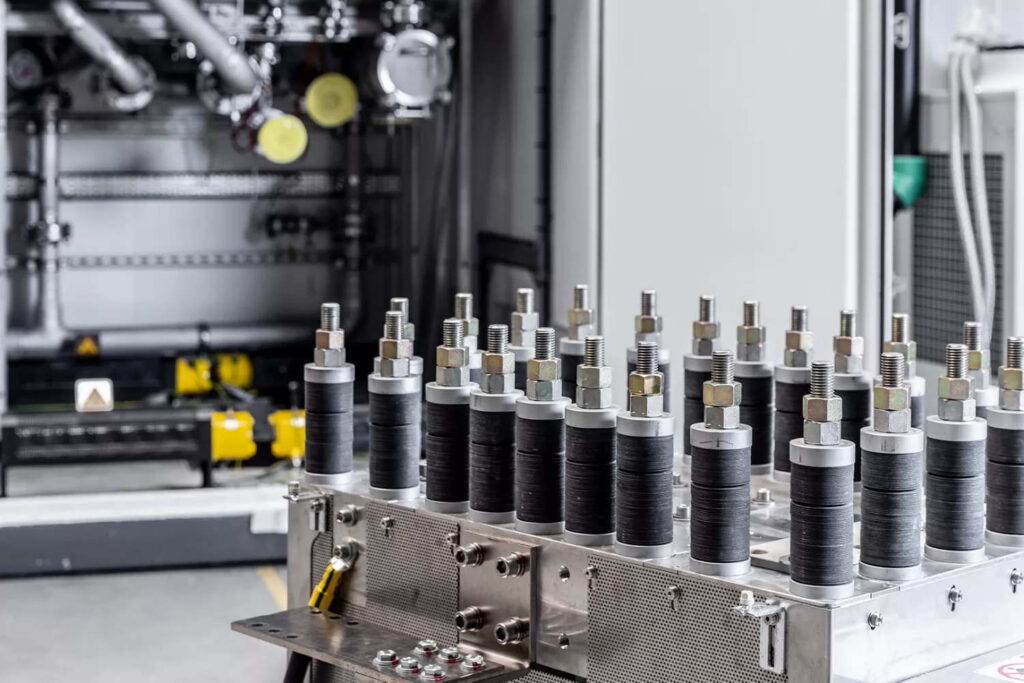

Application Background

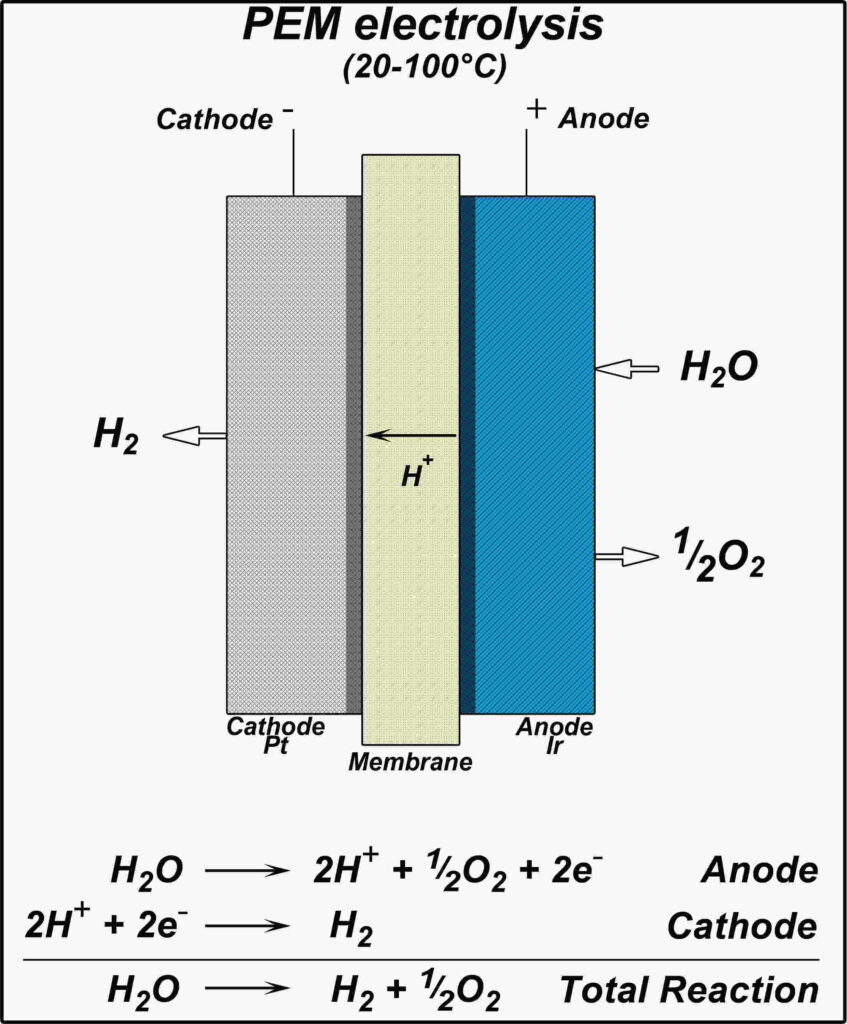

PEM electrolysers rely on precise level measurement and control to ensure stable operation and efficient hydrogen production. Radar level meters provide reliable, non-contact monitoring of ultrapure water (H₂O) split into hydrogen (H₂) and oxygen (O₂), enabling high-purity green hydrogen widely used in fuel cells, chemical synthesis, and green metallurgy.

With the global push towards “carbon peak and carbon neutrality” goals, green hydrogen has become a key pathway for energy transition. Among hydrogen production methods, the PEM (Proton Exchange Membrane) electrolysis technology is favored in the new energy sector due to its high efficiency, rapid response, and environmental friendliness.

In the system, the anode side injects ultrapure water, requiring level measurement to control the feed volume. The cathode side monitors residual water levels to ensure normal gas-liquid separation. Since the liquid surface is covered by highly pure hydrogen or oxygen gas during operation, the measurement devices must meet very high requirements for interference resistance, safety, and stability.

Typical Measurement Requirements and Challenges

| Measuring Task | Level Measurement |

|---|---|

| Measuring Point | Anode/Cathode Water Tanks |

| Medium | Ultrapure Water, Covered by Hydrogen or Oxygen |

| Measuring Range | 0 to 1 meter |

| Process Temperature | 0 to +70 °C |

| Process Pressure | 0 to 40 bar |

| Installation Environment | Compact Space with Internal Supports or Baffles |

| Special Challenges | Gas Coverage, Low Dielectric Constant, Vapor Interference, Non-contact Measurement Required |

Typical measurement challenges for PEM electrolysers include:

- Hydrogen/Oxygen gas coverage: The liquid surface is covered by flammable gases, making contact sensors prone to spark hazards.

- Ultrapure water characteristics: Low dielectric constant results in weak radar echoes, requiring high-frequency radar for effective detection.

- Restricted space: Compact tank structures with internal supports demand compact sensor antennas with focused beam angles.

- Condensation environment: Presence of vapor and slight condensation during operation requires radar with strong signal penetration and anti-interference ability.

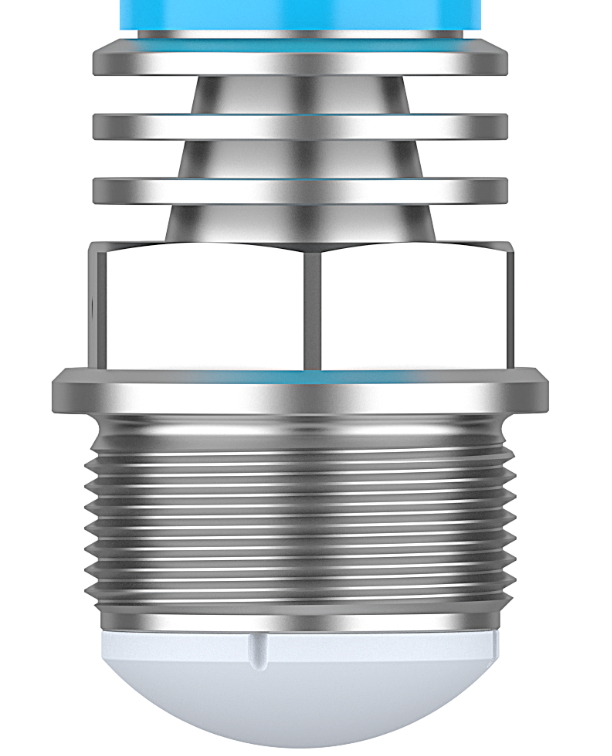

Solution: JWrada® Universal 80GHz Radar Level Meter

To address these measurement challenges, Jiwei Automation recommends the JWrada® series 80GHz universal radar level meter, featuring non-contact measurement and advanced FMCW (Frequency Modulated Continuous Wave) technology, delivering comprehensive upgrades in measurement accuracy, stability, and safety.

Key advantages of the JWrada® radar level meter include:

- 80GHz High Frequency: Provides narrower beam angle and stronger signal focus, easily penetrating confined tanks and avoiding internal structure interference.

- Non-contact Measurement: Avoids liquid contamination and mechanical wear, unaffected by gas or vapor, ensuring maintenance-free operation.

- High Sensitivity Echo Processing: Clearly detects liquid surface even with low dielectric constant ultrapure water under hydrogen or oxygen gas coverage.

- Flexible Process Connections: Supports threaded, flange, and hygienic connections with top or side mounting options.

- Smart Configuration: Supports Bluetooth remote commissioning via the Jiwei Smart Control app, significantly improving field efficiency.

Practical Application Results

In a renewable energy PEM hydrogen production project, the JWrada® radar level meter was deployed for anode feedwater control and cathode residual water monitoring. The installation environment was complex and confined; traditional contact probes suffered from contamination and frequent false alarms.

After switching to the JWrada® 80GHz radar meter, the customer reported:

- Level control accuracy stabilized within ±1 mm, with significantly faster system response;

- No false alarms on the hydrogen side, continuous operation exceeding 2000 hours without failure;

- Remote commissioning enabled parameter setup within minutes on site;

- Overall hydrogen production efficiency improved by approximately 7%, while reducing manual inspection frequency.

These results confirm the excellent performance of JWrada® in PEM electrolysers, especially its safety and maintenance advantages.

Three Core Advantages: Safety · Efficiency · Flexibility

| Advantage Category | Description |

|---|---|

| Safety | Non-contact design eliminates spark risk; suitable for hydrogen/oxygen atmospheres |

| Efficiency | Real-time level monitoring supports automated system control with fast response |

| Flexibility | Multiple installation and connection options; easy commissioning and maintenance-free operation |

JWrada® Radar Level Meter Specifications

| Parameter | Value |

|---|---|

| Measuring Frequency | 80GHz FMCW |

| Measuring Range | 0–120 meters (liquid/solid) |

| Accuracy | ±1 mm |

| Operating Temperature | -40 °C to +220 °C |

| Output Signals | 4…20 mA/HART, Modbus, Bluetooth commissioning |

| Protection Rating | IP66/IP68 (optional) |

Conclusion

PEM electrolysers impose stringent requirements on level measurement in terms of safety, accuracy, and adaptability. The JWrada® universal radar level meter from Jiwei Automation, with its advanced technology and extensive field experience, is setting new standards in level control for the new energy industry.

Amid the global hydrogen energy trend, selecting a truly reliable, intelligent, and adaptable level measurement device is key to ensuring efficient hydrogen production. Jiwei Automation is ready to partner with you to build a greener energy future.