Guide to Process Connection Abbreviations: Threads & Flanges (ANSI/ASME, BS, JIS, GB/T)

In industrial automation, process control, and instrumentation engineering, process connections are critical for reliable linking between pipelines, instruments, and equipment. Different countries and standards systems use varying naming conventions and abbreviations for connections. Understanding these abbreviations is essential for engineering design, procurement, and on-site installation. This article provides a complete overview of common threaded and flanged connection abbreviations, covering American (ANSI/ASME), British (BS), Japanese (JIS), and Chinese (GB/T) standards.

1. Threaded Connections

Threaded connections are widely used for instruments, piping, and valves. They can be classified into tapered threads and parallel threads. Common abbreviations include:

| Abbreviation | Full Name | Standard/System | Description |

|---|---|---|---|

| NPT | National Pipe Taper | ANSI/ASME B1.20.1 | Tapered pipe thread, commonly used for pressure sealing. |

| NPTF | National Pipe Taper Fuel | ANSI/ASME | Dry-seal tapered thread, leak-proof, suitable for fuel or gas. |

| BSPT | British Standard Pipe Taper | BS | Tapered pipe thread, widely used in the UK and Commonwealth countries. |

| BSPP | British Standard Pipe Parallel | BS | Parallel pipe thread, requires O-ring or gasket for sealing. |

| G | Gas Thread | ISO 228 | Parallel thread, ISO standard, commonly for low-pressure liquids and gases. |

| Rc | Rc Taper Thread | JIS B 0203 | Tapered pipe thread according to Japanese standard, commonly used in JIS. |

| Rp | Rp Parallel Thread | JIS B 0203 | Parallel pipe thread, requires sealing gasket. |

| M | Metric Thread | ISO / GB/T | Metric thread, e.g., M20x1.5. |

| PT | Pipe Thread | JIS B 0203 | Commonly used in gas or liquid pipeline connections. |

| G(M) | Gas (Metric) | JIS / ISO | Parallel thread, low gas-tightness requirement. |

Notes:

- Tapered threads seal through thread contact.

- Parallel threads require additional sealing, such as O-rings or gaskets.

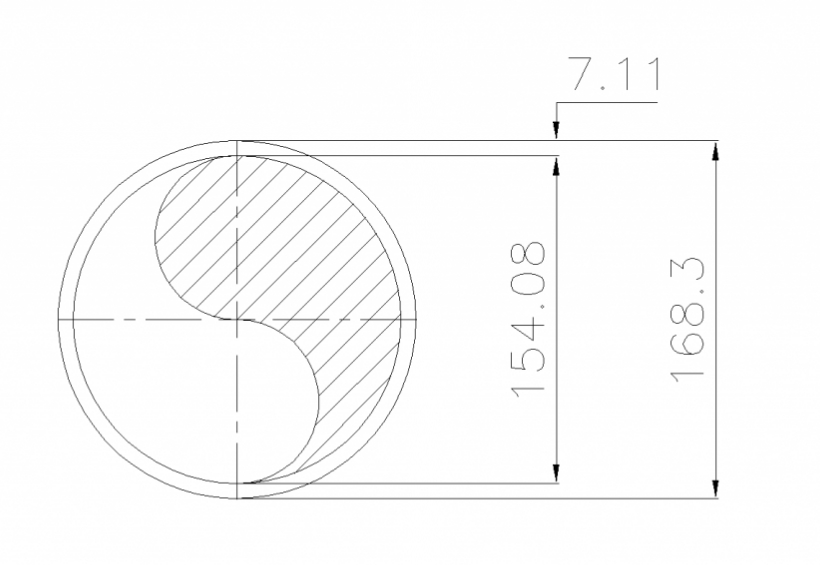

2. Flanged Connections

Flanged connections are widely used in pipelines and instrumentation. Abbreviations are based on flange type, structure, and standard.

| Abbreviation | Full Name | Standard/System | Description |

|---|---|---|---|

| RF | Raised Face | ANSI/ASME B16.5 | Raised face flange, commonly used sealing surface. |

| FF | Flat Face | ANSI/ASME B16.5 | Flat face flange, used with flat gasket. |

| SO | Slip-On | ANSI/ASME B16.5 | Slip-on flange, pipe inserted and welded. |

| WN | Weld Neck | ANSI/ASME B16.5 | Weld-neck flange, high pressure capacity. |

| SW | Socket Weld | ANSI/ASME B16.11 | Socket weld flange, suitable for small-diameter high-pressure pipes. |

| BL | Blind | ANSI/ASME B16.5 | Blind flange, used to close pipe ends. |

| SORF | Slip-On Raised Face | ANSI/ASME | Slip-on flange with raised face, common US designation. |

| CL150 | Class 150 | ANSI/ASME | Flange pressure rating, Class 150 ≈ 1.6 MPa. |

| CL300 | Class 300 | ANSI/ASME | Flange pressure rating, Class 300 ≈ 4.0 MPa. |

| PN | Pressure Nominal | GB/T | Nominal pressure rating in MPa. |

| JIS 5K / 10K / 16K | Japan Industrial Standard | JIS B 2220 | Flange pressure ratings, 5K ≈ 0.5 MPa, 16K ≈ 1.6 MPa. |

| JIS RF | Raised Face Flange | JIS | Raised face flange per JIS. |

| JIS FF | Flat Face Flange | JIS | Flat face flange per JIS. |

| GB | Chinese Standard Flange | GB/T 9112 / 9113 / 12228 | Example: GB/T 9112-2000 PN1.6 MPa raised face flange. |

| DIN | German Standard Flange | DIN 2573 / 2631 | Common PN16, PN25 ratings. |

| BS | British Standard Flange | BS 10 / BS 4504 | Compatible with British pipe systems. |

3. Common Examples

| Notation | Meaning |

|---|---|

| DN40, PN16 RF | Nominal diameter 40 mm, Chinese standard pressure 1.6 MPa, raised face flange |

| NPS 1½”, CL150, SORF | US standard pipe 1½”, Class 150, slip-on raised face flange |

| Rc 1″, JIS 10K RF | Japanese Rc 1″ tapered thread, 10K flange rating, raised face flange |

💡 Notes:

- US flanges use Class (150#, 300#, 600#…), while Chinese and Japanese standards use PN or K (MPa).

- Tapered threads seal via thread itself; parallel threads or flanges require gasket or O-ring.

- Mixed notation (e.g., DN + 150#) is common in local projects but still represents US Class rating.

4. Selection Guidelines

- Standard Matching: Threads and flanges must match the same standard system.

- Pressure Rating: Convert US Class to PN or K using pressure-temperature tables.

- Installation & Sealing: Tapered threads seal through threads; parallel threads or flanges require gaskets or O-rings.

- Mixed Notation Habit: DN + 150# is commonly used but represents US Class.

5. Conclusion

Mastering process connection abbreviations and standards helps to:

- Quickly identify thread and flange types

- Avoid interface mismatch in field installation

- Ensure accurate procurement and technical communication

For both domestic and international projects, understanding ANSI/ASME, BS, JIS, and GB/T connection abbreviations is essential knowledge for engineers and technical personnel.